ISO/R 1457:1970/Amd 1

(Amendment)Title missing - Legacy paper document

Title missing - Legacy paper document

General Information

Relations

Standards Content (Sample)

Ref, No. : IW/R 1457-1970/A1-1972 (E)

-1-

UDC 669.387’248’268 : 620.198

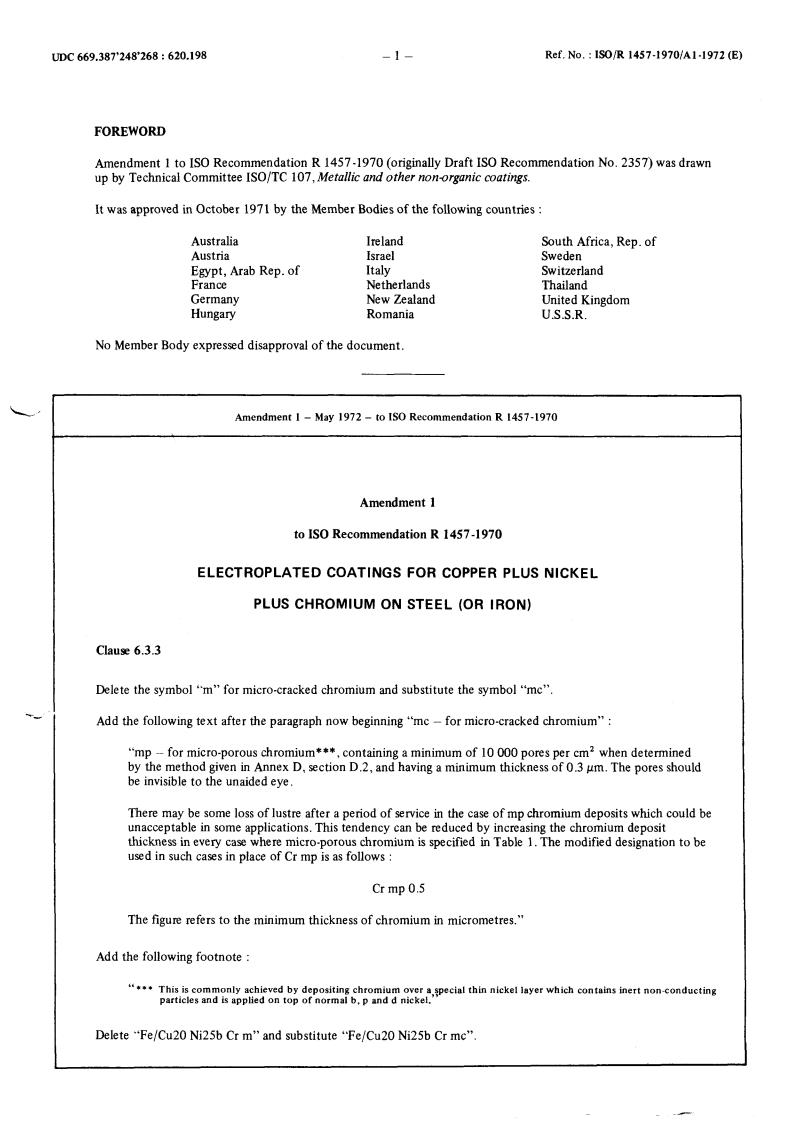

FOREWORD

Amendment 1 to IS0 Recommendation R 1457-1970 (originally Draft IS0 Recommendation No. 2357) was drawn

up by Technical Committee ISO/TC 107, Metallic and other non-organic coatings.

It was approved in October 1971 by the Member Bodies of the following countries :

Australia Ireland South Africa, Rep. of

Austria Israel Sweden

Egypt, Arab Rep. of Italy Switzerland

France Netherlands Thailand

Germany New Zealand United Kingdom

Hungary Romania U.S.S.R.

No Member Body expressed disapproval of the document.

Amendment 1 - May 1972 - to IS0 Recommendation R 1457-1970

Amendment 1

to IS0 Recommendation R 1457-1970

ELECTROPLATED COATINGS FOR COPPER PLUS NICKEL

PLUS CHROMIUM ON STEEL (OR IRON)

Clause 6.3.3

Delete the symbol “m” for micro-cracked chromium and substitute the symbol “mc”.

Add the following text after the paragraph now beginning “mc - for micro-cracked chromium” :

“mp - for micro-porous chromium***, containing a minimum of 10 O00 pores per cmz when determined

by the method given in Annex D, section D.2, and having a minimum thickness of 0.3 pm. The pores should

be invisible to the unaided eye.

There may be some loss of lustre after a period of service in the case of mp chromium deposits which could be

unacceptable in some applications. This tendency can be reduced by increasing the chromium deposit

thickness in every case where micro-porous chromium is specified in Table 1. The modified designation to be

used in such cases in place of Cr mp is as follows :

Cr mp 0.5

The figure refers to the minimum thickness of chromium in micrometres.”

Add the following footnote :

“ *** This is commonly achieved by depositing chromium over a,specia

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.