ISO/TS 19870:2023

(Main)Hydrogen technologies — Methodology for determining the greenhouse gas emissions associated with the production, conditioning and transport of hydrogen to consumption gate

Hydrogen technologies — Methodology for determining the greenhouse gas emissions associated with the production, conditioning and transport of hydrogen to consumption gate

ISO 14044 requires the goal and scope of an LCA to be clearly defined and be consistent with the intended application. Due to the iterative nature of LCA, it is possible that the LCA scope needs to be refined during the study. This document specifies methodologies that can be applied to determine the carbon footprint of a product (CFP) or partial CFP of a hydrogen product in line with ISO 14067. The goals and scopes of the methodologies correspond to either approach a) or b), given below, that ISO 14040:2006, A.2 gives as two possible approaches to LCA. a) An approach that assigns elementary flows and potential environmental impacts to a specific product system, typically as an account of the history of the product. b) An approach that studies the environmental consequences of possible (future) changes between alternative product systems. Approaches a) and b) have become known as attributional and consequential, respectively, with complementary information accessible in the ILCD handbook.[1] There are numerous pathways to produce hydrogen from various primary energy sources. This document describes the requirements and evaluation methods applied to several hydrogen production pathways of interest: electrolysis, steam methane reforming (with carbon capture and storage), co-production and coal gasification (with carbon capture and storage), auto-thermal reforming (with carbon capture and storage), hydrogen as a co-product in industrial applications and hydrogen from biomass waste as feedstock. This document also considers the GHG emissions due to the conditioning or conversion of hydrogen into different physical forms and chemical carriers: — hydrogen liquefaction; — production, transport and cracking of ammonia as a hydrogen carrier; — hydrogenation, transport and dehydrogenation of liquid organic hydrogen carriers (LOHCs). This document considers the GHG emissions due to hydrogen and/or hydrogen carriers’ transport up to the consumption gate. It is possible that future revisions of this document will consider additional hydrogen production, conditioning, conversion and transport methods. This document applies to and includes every delivery along the supply chain up to the final delivery to the consumption gate (see Figure 2 in the Introduction). This document also provides additional information related to evaluation principles, system boundaries and expected reported metrics in the form of Annexes A to K, that are accessible via the online ISO portal (https://standards.iso.org/iso/ts/19870/ed-1/en).

Technologies de l'hydrogène — Méthodologie pour déterminer les émissions de gaz à effet de serre associées à la production, au conditionnement et au transport de l'hydrogène jusqu'au point de consommation

General Information

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 19870

First edition

2023-11

Hydrogen technologies —

Methodology for determining the

greenhouse gas emissions associated

with the production, conditioning and

transport of hydrogen to consumption

gate

Technologies de l'hydrogène — Méthodologie pour déterminer

les émissions de gaz à effet de serre associées à la production, au

conditionnement et au transport de l'hydrogène jusqu'au point de

consommation

Reference number

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

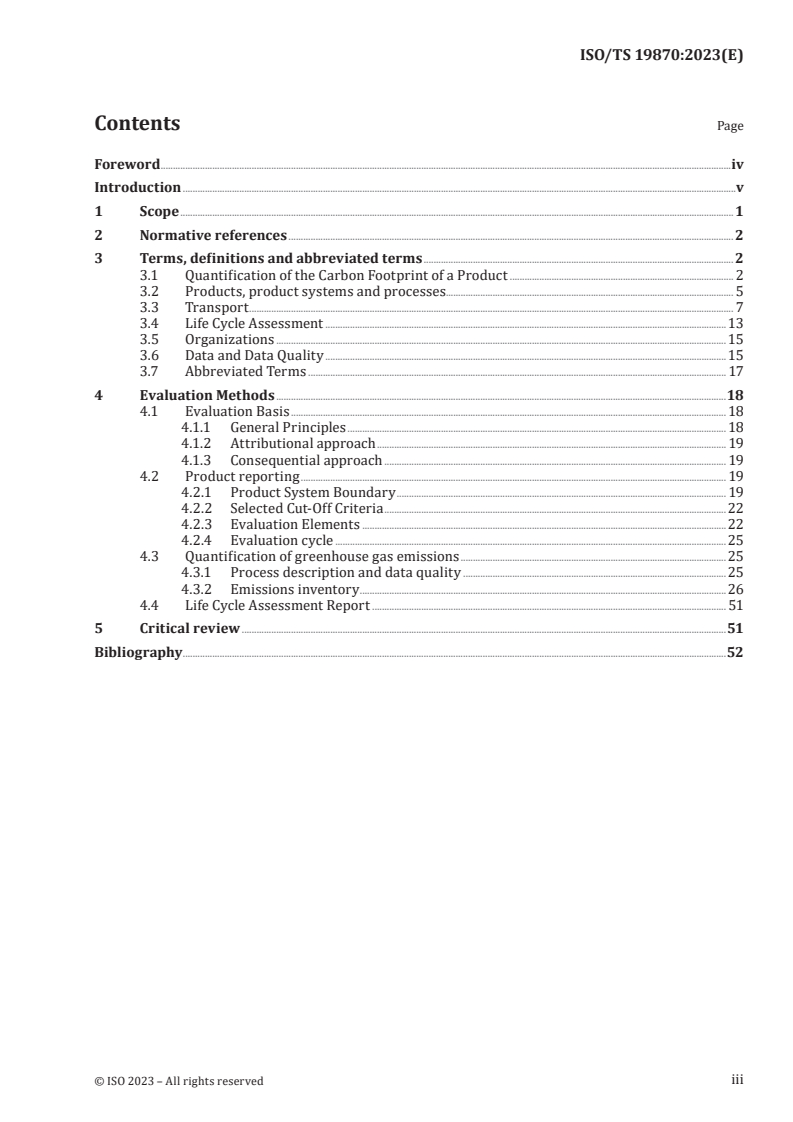

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 2

3 Terms, definitions and abbreviated terms . 2

3.1 Quantification of the Carbon Footprint of a Product . 2

3.2 Products, product systems and processes . 5

3.3 Transport . 7

3.4 Life Cycle Assessment .13

3.5 Organizations . 15

3.6 Data and Data Quality .15

3.7 Abbreviated Terms . 17

4 Evaluation Methods .18

4.1 Evaluation Basis . 18

4.1.1 General Principles . 18

4.1.2 Attributional approach . 19

4.1.3 Consequential approach . 19

4.2 Product reporting . 19

4.2.1 Product System Boundary . 19

4.2.2 Selected Cut-Off Criteria . 22

4.2.3 Evaluation Elements .22

4.2.4 Evaluation cycle . 25

4.3 Quantification of greenhouse gas emissions . 25

4.3.1 Process description and data quality . 25

4.3.2 Emissions inventory .26

4.4 Life Cycle Assessment Report . 51

5 Critical review .51

Bibliography .52

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 197, Hydrogen technologies, Subcommittee

SC 1, Hydrogen at scale and horizontal energy systems.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

Introduction

The Paris Agreement was adopted at the UN Climate Change conference (COP21) with the aims of:

strengthening the global response to the threat of climate change, restricting global temperature rise

to below 2 °C above pre-industrial levels and pursuing efforts to limit the temperature increase to 1,5 °C

above pre-industrial levels. To meet these goals, greenhouse gas (GHG) emissions need to be reduced by

about 45 % from 2010 levels by 2030, reaching net zero in 2050 (IPCC, 2018; UNFCCC, 2021).

GHG initiatives on mitigation rely on the quantification, monitoring, reporting and verification of GHG

emissions and/or removals. International Standards that support the transformation of scientific

knowledge into tools can help in reaching the targets of the Paris Agreement to address climate change.

ISO 14040 and ISO 14044 define the principles, requirements and guidelines identified in existing

International Standards on life cycle assessment (LCA). The ISO 14060 series provides clarity and

consistency for quantifying, monitoring, reporting and validating or verifying GHG emissions

and removals to support sustainable development through a low-carbon economy. It also benefits

organizations, project proponents and stakeholders worldwide by providing clarity and consistency on

quantifying, monitoring, reporting and validating or verifying GHG emissions and removals.

ISO 14067 is based on the principles, requirements and guidelines on LCA identified in ISO 14040 and

ISO 14044 and aims to set specific requirements for the quantification of a carbon footprint (CFP) and

a partial CFP.

ISO 14067 defines the principles, requirements and guidelines for the quantification of the carbon

footprint of products. Its aim is to quantify GHG emissions associated with the lifecycle stages of a

product, beginning with resource extraction and raw material sourcing and extending through the

production, use and end-of-life stages of the product.

Figure 1 illustrates the relationship between ISO 14067 and other ISO documents on LCA.

PCR Product category rule

Figure 1 — Relationship between standards beyond the GHG management family of standards

(source ISO 14067:2018)

Hydrogen can be produced from diverse sources including renewables, nuclear and fossil fuels using

carbon capture, utilization and storage (CCUS) to reduce the emissions associated with its production.

Hydrogen can be used to decarbonize numerous sectors including transport, industrial manufacturing

and power generation.

v

A particular challenge is that identical hydrogen molecules can be produced and combined from

sources that have different GHG intensities. Similarly, hydrogen-based fuels and derivatives will be

indistinguishable and can be produced from hydrogen combined with a range of fossil and low-carbon

inputs. Indeed, some of the products made from hydrogen (e.g. electricity) can themselves be used in the

production of hydrogen. Accounting standards for different sources of hydrogen along the supply chain

(see Figure 2) will be fundamental to creating a market for low-carbon hydrogen, and these standards

need to be agreed upon internationally. Additionally, there is the possibility that consumption gates

are not located in proximity to hydrogen production gates, requiring hydrogen transport. ISO 14083

gives guidelines for the quantification and reporting of GHG emissions arising from transport chain

operations.

A mutually recognized international framework that is robust, avoids miscounting or double counting

of environmental impacts is needed. Such a framework will provide a mutually agreed approach to

“guaranties" or “certificates” of origin, and cover greenhouse gas inputs used for hydrogen production,

conditioning, conversion and transport.

This document aims at increasing the methodologies that should be applied, in line with ISO 14067, to

the specific case of the hydrogen value chain, covering different production processes and other parts

of the value chain, such as conditioning hydrogen in different physical states, conversion of hydrogen

into different hydrogen carriers and the subsequent transport up to the consumption gate.

Figure 2 — Examples of hydrogen supply chain

vi

TECHNICAL SPECIFICATION ISO/TS 19870:2023(E)

Hydrogen technologies — Methodology for determining

the greenhouse gas emissions associated with the

production, conditioning and transport of hydrogen to

consumption gate

1 Scope

ISO 14044 requires the goal and scope of an LCA to be clearly defined and be consistent with the

intended application. Due to the iterative nature of LCA, it is possible that the LCA scope needs to be

refined during the study.

This document specifies methodologies that can be applied to determine the carbon footprint of a

product (CFP) or partial CFP of a hydrogen product in line with ISO 14067. The goals and scopes of the

methodologies correspond to either approach a) or b), given below, that ISO 14040:2006, A.2 gives as

two possible approaches to LCA.

a) An approach that assigns elementary flows and potential environmental impacts to a specific

product system, typically as an account of the history of the product.

b) An approach that studies the environmental consequences of possible (future) changes between

alternative product systems.

Approaches a) and b) have become known as attributional and consequential, respectively, with

[1]

complementary information accessible in the ILCD handbook.

There are numerous pathways to produce hydrogen from various primary energy sources. This

document describes the requirements and evaluation methods applied to several hydrogen production

pathways of interest: electrolysis, steam methane reforming (with carbon capture and storage), co-

production and coal gasification (with carbon capture and storage), auto-thermal reforming (with

carbon capture and storage), hydrogen as a co-product in industrial applications and hydrogen from

biomass waste as feedstock.

This document also considers the GHG emissions due to the conditioning or conversion of hydrogen into

different physical forms and chemical carriers:

— hydrogen liquefaction;

— production, transport and cracking of ammonia as a hydrogen carrier;

— hydrogenation, transport and dehydrogenation of liquid organic hydrogen carriers (LOHCs).

This document considers the GHG emissions due to hydrogen and/or hydrogen carriers’ transport up to

the consumption gate.

It is possible that future revisions of this document will consider additional hydrogen production,

conditioning, conversion and transport methods.

This document applies to and includes every delivery along the supply chain up to the final delivery to

the consumption gate (see Figure 2 in the Introduction).

This document also provides additional information related to evaluation principles, system boundaries

and expected reported metrics in the form of Annexes A to K, that are accessible via the online ISO

portal (https://standards . iso. org/i so/t s/19870/ ed -1/ en ).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 14040:2006, Environmental management — Life cycle assessment — Principles and framework

ISO 14044, Environmental management — Life cycle assessment — Requirements and guidelines

ISO 14067:2018, Greenhouse gases — Carbon footprint of products — Requirements and guidelines for

quantification

ISO 14083:2023, Greenhouse gases — Quantification and reporting of greenhouse gas emissions arising

from transport chain operations

ISO/TS 14071, Environmental management — Life cycle assessment — Critical review processes and

reviewer competencies: Additional requirements and guidelines to ISO 14044:2006

3 Terms, definitions and abbreviated terms

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1 Quantification of the Carbon Footprint of a Product

3.1.1

allocation

partitioning the input (3.2.8) or output (3.2.10) flows of a process or a product system (3.2.3) between

the product system under study and one or more other product systems

[SOURCE: ISO 14040:2006 and ISO 14040:2006/AMD 1:2020]

3.1.2

carbon footprint of a product

CFP

sum of greenhouse gas emissions (3.1.12) and greenhouse gas removals (3.1.4) in a product system (3.2.3),

expressed as CO equivalent (3.1.10) and based on a life cycle assessment (3.4.5) using the single impact

category of climate change

Note 1 to entry: A CFP can be disaggregated into a set of figures identifying specific GHG emissions (3.1.12) and

removals (3.1.4). A CFP can also be disaggregated into the stages of the life cycle (3.4.4).

Note 2 to entry: The results of the quantification of CFP (3.1.8) are documented in the CFP study report expressed

in mass of CO e (3.1.11) per functional unit (3.2.14).

[SOURCE: ISO 14067:2018, 3.1.1.1]

3.1.3

partial CFP

sum of greenhouse gas emissions (3.1.12) and greenhouse gas removals (3.1.4) of one or more selected

process(es) in a product system (3.2.3) expressed as CO equivalents (3.1.10) and based on the selected

stages or processes within the life cycle (3.4.4)

Note 1 to entry: A partial CFP is based on or compiled from data related to (a) specific process(es) or footprint

information modules (defined in ISO 14026:2017, 3.1.4), which is (are) part of a product system (3.2.3) and

can form the basis for quantification of a carbon footprint of a product (CFP). More detailed information on

information modules is given in ISO 14025:2006, 5.4.

Note 2 to entry: The results of the quantification of the partial CFP are documented in the CFP study report

expressed in mass of CO e (3.1.10) per declared unit.

3.1.4

greenhouse gas removal

GHG removal

withdrawal of a greenhouse gas (3.1.9) from the atmosphere

[SOURCE: ISO 14067:2018, 3.1.2.6]

3.1.5

CFP study

all activities that are necessary to quantify and report the carbon footprint of a product (3.1.2) or a

partial CFP (3.1.3)

[SOURCE: ISO 14067:2018, 3.1.1.4]

3.1.6

product category

group of products that can fulfil equivalent functions

[SOURCE: ISO 14025:2006, 3.12]

3.1.7

production batch

amount of products produced by a device between any two points in time selected by the operator

3.1.8

quantification of CFP

activities that result in the determination of the carbon footprint of a product (3.1.2) or a partial CFP

(3.1.3)

Note 1 to entry: Quantification of the CFP (3.1.2) or the partial CFP (3.1.3) is part of the CFP study (3.1.5)

[SOURCE: ISO 14067:2018, 3.1.1.6]

3.1.9

greenhouse gas

GHG

gaseous constituent of the atmosphere, both natural and anthropogenic, that absorbs and emits

radiation at specific wavelengths within the spectrum of infrared radiation emitted by the Earth’s

surface, the atmosphere and clouds

Note 1 to entry: For a list of greenhouse gases (3.1.9), see the latest IPCC Assessment Report (currently carbon

dioxide (CO ); methane (CH ); nitrous oxide (N O)). Other GHGs are not considered relevant for this document.

2 4 2

Note 2 to entry: Water vapour and ozone, which are anthropogenic as well as natural greenhouse gases (3.1.9), are

not included in the carbon footprint of a product (3.1.2).

Note 3 to entry: The focus of this document is limited to long-lived GHGs and it therefore excludes climate effects

due to changes in surface reflectivity (albedo) and short-lived radiative forcing agents (e.g. black carbon and

aerosols).

[SOURCE: ISO 14067:2018, 3.1.2.1]

3.1.10

carbon dioxide equivalent

CO equivalent

CO e

unit for comparing the radiative forcing of a greenhouse gas (3.1.9) to that of carbon dioxide

Note 1 to entry: Mass of a greenhouse gas is converted into CO equivalents by multiplying the mass of the

greenhouse gas (3.1.9) by the corresponding global warming potential (3.1.11) or global temperature change

potential (GTP) of that gas.

Note 2 to entry: In the case of GTP, CO equivalent is the unit for comparing the change in global mean surface

temperature caused by a greenhouse gas to the temperature change caused by carbon dioxide.

[SOURCE: ISO 14067:2018, 3.1.2.2]

3.1.11

global warming potential

GWP

index, based on radiative properties of greenhouse gases (3.1.9) (GHG) measuring the radiative forcing

following a pulse emission of a unit mass of a given GHG in the present-day atmosphere integrated over

a chosen time horizon, relative to that of carbon dioxide (CO )

Note 1 to entry: “Index” as used in this document is a “characterization factor” as defined in ISO 14040:2006,

3.37.

Note 2 to entry: A “pulse emission” is an emission at one point in time.

[SOURCE: ISO 14067:2018, 3.1.2.4]

3.1.12

greenhouse gas emission

GHG emission

release of a greenhouse gas (3.1.9) into the atmosphere

[SOURCE: ISO 14067:2018, 3.1.2.5]

3.1.13

greenhouse gas emission factor

GHG emission factor

coefficient relating activity data with the greenhouse gas emission (3.1.3)

[SOURCE: ISO 14067:2018, 3.1.2.7]

3.1.14

capital goods emission

CAPEX emission

GHG emissions (3.1.12) related to the manufacturing of capital goods

3.1.15

subdivision

virtual subdivision

decomposition of the analysed unit process into physically or virtually distinguishable sub-process

steps with the possibility to collect data exclusively for those sub-processes

3.2 Products, product systems and processes

3.2.1

product

any goods or service

Note 1 to entry: The product can be categorized as follows:

— services (e.g. transport);

— software (e.g. computer program, dictionary);

— hardware (e.g. engine mechanical part);

— processed materials (e.g. lubricant).

[SOURCE: ISO 14040:2006, 3.9]

3.2.2

product flow

products (3.2.1) entering from or leaving to another product system (3.2.3)

[SOURCE: ISO 14040:2006, 3.27]

3.2.3

product system

collection of unit processes with elementary flows (3.2.16) and product flows (3.2.2), performing one or

more defined functions and which models the life cycle (3.4.4) of a product (3.2.1)

[SOURCE: ISO 14044:2006, 3.28]

3.2.4

co-product

two or more products (3.2.1) coming from the same unit process or product system (3.2.3)

[SOURCE: ISO 14040:2006, 3.10]

3.2.5

conditioning

means changing the physical conditions (temperature, pressure) of a species

Note 1 to entry: In this document, examples are changing the pressure of gaseous hydrogen or liquefying gaseous

hydrogen.

3.2.6

conversion

means changing the chemicals conditions of a species

Note 1 to entry: In this document, examples are changing hydrogen molecules into ammonia or LOHCs.

3.2.7

heating value

amount of energy released when a fuel is burned completely

Note 1 to entry: Care must be taken not to confuse higher heating values (HHVs) and lower heating values (LHVs).

3.2.8

input

product (3.2.1), material or energy flow (3.2.17) that enters a unit process

Note 1 to entry: Products (3.2.1) and materials include raw materials, intermediate products (3.2.9) and co-

products (3.2.4).

[SOURCE: ISO 14040:2006, 3.21]

3.2.9

intermediate product

output from a unit process that is input to other unit processes that require further transformation

within the system

[SOURCE: ISO 14040:2006, 3.23]

3.2.10

output

product (3.2.1), material or energy flow (3.2.17) that leaves a unit process (3.2.13)

Note 1 to entry: Products (3.2.1), and materials include raw materials, intermediate products (3.2.9), co-products

(3.2.4) and releases (3.4.11).

[SOURCE: ISO 14040:2006, 3.25]

3.2.11

system boundary

boundary based on a set of criteria representing which unit processes (3.2.13) are a part of the system

under study

[SOURCE: ISO 14040:2006/AMD 1:2020, 3.32]

3.2.12

system expansion

concept of expanding the product system (3.2.3) to include additional functions related to the co-

products (3.2.4)

Note 1 to entry: The product system (3.2.3) that is substituted by the co-product (3.2.4) is integrated in the product

system (3.2.3) under study. In practice, the co-products (3.2.4) are compared to other substitutable products, and

the environmental burdens associated with the substituted product(s) are subtracted from the product system

(3.2.3) under study. The identification of this substituted system is done in the same way as the identification of

the upstream system for intermediate product (3.2.9) inputs (3.2.8). See also ISO/TR 14049:2012, 6.4

Note 2 to entry: The application of system expansion (3.2.12) involves an understanding of the market for the co-

products (3.2.4). Decisions about system expansion (3.2.12) can be improved through understanding the way co-

products (3.2.4) compete with other products, as well as the effects of any product substitution upon production

practices in the industries impacted by the co-products (3.2.4).

Note 3 to entry: Can be referred to as system expansion (3.2.12) and also as expanding the system boundary

(3.2.11).

[SOURCE: ISO 14044:2006/AMD 2:2020, D.2.1]

3.2.13

process

set of interrelated or interacting activities that transforms inputs (3.2.8) into outputs (3.2.10)

[SOURCE: ISO 14044:2006, 3.11]

3.2.14

functional unit

quantified performance of a product system (3.2.3) for use as a reference unit

Note 1 to entry: As the carbon footprint of a product treats information on a product basis, an additional

calculation based on a declared unit can be presented.

[SOURCE: ISO 14040:2006, 3.20]

3.2.15

reference flow

measure of the inputs (3.2.8) to or outputs (3.2.10) from processes (3.2.13) in a given product system

(3.2.3) required to fulfil the function expressed by the functional unit (3.2.14)

Note 1 to entry: In the case of a partial CFP (3.1.3), the reference flow (3.2.15) refers to the declared unit.

[SOURCE: ISO 14067:2018, 3.1.3.9]

3.2.16

elementary flow

material or energy entering the system being studied that has been drawn from the environment

without previous human transformation, or material or energy leaving the system being studied that is

released into the environment without subsequent human transformation

Note 1 to entry: “Environment” is defined in ISO 14001:2015, 3.2.1.

[SOURCE: ISO 14044:2006, 3.12]

3.2.17

energy flow

input (3.2.8) to or output (3.2.10) from a unit process or product system (3.2.3), quantified in energy

units

Note 1 to entry: Energy flow that is an input can be called an energy input; energy flow that is an output can be

called an energy output.

[SOURCE: ISO 14040:2006, 3.13]

3.3 Transport

3.3.1

cargo

goods or sets of goods (liquid, solid or gaseous) transported from one place to another on a means of

transport (3.3.5)

3.3.2

consignment

separately identifiable amount of freight (3.3.3) transported from one consignor to one consignee via

one or more modes of transport

Note 1 to entry: Although “consignment” and “shipment” are common terms often considered as synonyms, in

this document and other technical publications, a consignment is differentiated to a shipment. Indeed, a shipment

refers to a grouping of freight corresponding to the shipper needs, whereas a consignment refers a grouping of

freight according to a carrier or freight forwarder’s transport solutions.

[SOURCE: ISO 14083:2023, 3.1.4]

3.3.3

freight

goods, materials, commodities, parcels, etc. being transported from one location to another

[SOURCE: ISO 14083:2023, 3.1.7]

3.3.4

fuel consumption

amount of energy used by a means of transport (3.3.5) to fulfil a given task

3.3.5

means of transport

modes of transport such as inland waterway, pipeline, rail and road that are used for the transport of

freight

3.3.6

route

journey (to be) taken to get from one point to another point

3.3.7

delivery gate

location where products have their custody transferred according to contractual arrangements

between the purchaser and the provider.

3.3.8

consumption gate

location of the final delivery of the product along its complete supply chain.

3.3.9

transport

movement of freight (3.3.3) from one location to another performed by modes of transport

Note 1 to entry: The term “transport” in general is used for movement supported by means.

3.3.10

vehicle

any means of transport (3.3.5)

Note 1 to entry: Within this standard, this definition includes vessels (watercraft and aircraft like ships, boats,

and planes), for reasons of simplification only. Pipelines (see 3.3.24) are not considered a vehicle.

[SOURCE: ISO 14083:2023, 3.1.35, modified Note 1 to entry]

3.3.11

empty trip

section of the route of a vehicle (3.3.10) during which no freight or passenger is transported

[SOURCE: ISO 14083:2023, 3.1.5]

3.3.12

distance adjustment factor

DAF

ratio between the actual distance and the transport activity distance, related to the same origin and

destination locations

EXAMPLE Ratio between “actual distance” and “shortest feasible distance (3.3.31)”

[SOURCE: ISO 14083:2023, 3.3.5]

3.3.13

fleet

set of vehicles (3.3.10) operated by one transport service operator

[SOURCE: ISO 14083:2023, 3.1.6]

3.3.14

great circle distance

GCD

transport distance determined as the shortest distance between any two points measured along the

surface of a sphere

[SOURCE: ISO 14083:2023]

3.3.15

hub

DEPRECATED: node

DEPRECATED: site

DEPRECATED: station

DEPRECATED: facility

DEPRECATED: centre

DEPRECATED: depot

location where passengers transfer and/or freight (3.3.3) is transferred from one vehicle (3.3.10) or

mode of transport to another before, after or between different elements of a transport chain

Note 1 to entry: Hubs include, but are not limited to, rail/road terminals, cross-docking sites, airport terminals,

terminals at seaports and distribution centres.

[SOURCE: ISO 14083:2023, 3.1.8]

3.3.16

hub activity

parameter that quantifies the throughput (3.3.29) of a hub (3.3.15)

[SOURCE: ISO 14083:2023, 3.1.9]

3.3.17

hub equipment

equipment and facilities used within a hub (3.3.15) to transfer freight (3.3.3) or passengers

[SOURCE: ISO 14083:2023, 3.1.10]

3.3.18

hub operation

operation in order to transfer freight (3.3.3) or passengers through a hub (3.3.15)

[SOURCE: ISO 14083:2023, 3.1.11]

3.3.19

hub operation category

HOC

group of hub operations (3.3.18) that share similar characteristics

Note 1 to entry: ISO 14083:2023, Annex H contains examples of HOCs.

[SOURCE: ISO 14083:2023, 3.1.12]

3.3.20

hub operator

entity that carries out hub operations (3.3.18) involving carriage of freight (3.3.3) or passengers or both

[SOURCE: ISO 14083:2023, 3.1.13]

3.3.21

hub service

service provided within a hub transport chain element

[SOURCE: ISO 14083:2023, 3.1.14]

3.3.22

load

quantity or nature of is the freight being carried by a vehicle (3.3.10)

3.3.23

load factor

ratio of the actual load (3.3.22) and the maximum authorized load of one means of transport (3.3.5)

Note 1 to entry: Different dimensions are used for the measurement of the capacity, such as mass and volume.

[SOURCE: ISO 14083:2023, 3.1.15]

3.3.24

packaging

materials used for the containment, protection, handling, delivery and presentation of freight (3.3.3)

Note 1 to entry: Packaging may be further categorized into:

— primary packaging, which is designed to come into direct contact with the product;

— secondary packaging, which is designed to contain one or more products together with any primary

packaging required;

— transport packaging

[SOURCE: ISO 14083:2023, 3.4.2]

3.3.25

pipeline

long continuous line of pipes, including ancillary equipment, used for transporting freight (3.3.3).

[SOURCE: ISO 14083:2023, 3.1.17]

3.3.26

pipeline transport

movement of a medium (liquid, gas, liquefied gas, slurry) through a system of pipes from one location

to another

[SOURCE: ISO 14083:2023, 3.1.18]

3.3.27

round trip

group of sequential journeys that start and end in the same place, whatever the intermediate routing

[SOURCE: ISO 14083:2023, 3.1.19]

3.3.28

shipment

identifiable collection of one or more freight (3.3.3) items (available to be) transported together from

the original shipper to the ultimate consignee

Note 1 to entry: A shipment may be transported in one or a multiple number of consignments

Note 2 to entry: A shipment can be aggregated or disaggregated to different consignments according to the

requirements of the means of transport on any one element of the transport chain, e.g. single bulk units and

packages can be aggregated on a pallet and such pallet can be handed over as a unit for aggregation in a container,

which in turn is treated as a consignment in a vehicle (3.3.10)

Note 3 to entry: Although “consignment” and “shipment” are common terms often considered as synonyms, in

this document and other technical publications, a consignment is differentiated to a shipment. Indeed, a shipment

refers to a grouping of freight (3.3.3) corresponding to the shipper needs, whereas a consignment refers a

grouping of freight (3.3.3) according to a carrier or freight (3.3.3) forwarder’s transport solutions.

[SOURCE: ISO 14083:2023, 3.1.20]

3.3.29

throughput

quantity of passengers or freight (3.3.3) handled, sorted, cross-docked or transferred within and

between modes at a hub (3.3.15)

[SOURCE: ISO 14083:2023, 3.1.21]

3.3.30

transhipment

action by which freight (3.3.3) is transferred from one means of transport (3.3.5) to another during the

course of one transport chain

[SOURCE: ISO 14083:2023, 3.1.22]

3.3.31

shortest feasible distance

SDF

DEPRECATED: planned distance

DEPRECATED: network distance

transport distance determined as the distance achievable by the shortest practical route available

according to the infrastructure options for a particular vehicle (3.3.10) type

Note 1 to entry: “Shortest practical route” implies that small detours from the shortest distance, e.g. to avoid

congested city centres or rural roads unsuitable for certain vehicle (3.3.10) sizes, can be included.

[SOURCE: ISO 14083:2023, 3.1.27.3]

3.3.32

transport activity

parameter that quantifies passenger or freight (3.3.3) transport

[SOURCE: ISO 14083:2023, 3.1.24]

3.3.33

transport activity distance

transport distance related to passengers or freight (3.3.3) moved, used as a parameter for calculation of

transport activity (3.3.32)

[SOURCE: ISO 14083:2023, 3.1.27.4]

3.3.34

transport chain

sequence of elements related to freight (3.3.3) or a (group of) passenger(s) that, when taken together,

constitutes its movement from an origin to a destination

Note 1 to entry: A passenger or a group of passengers can include their luggage and, if any, their vehicles

Note 2 to entry: Where there are two or more elements, in the majority of cases, one of them implies that the

freight (3.3.3) or passengers use a hub (3.3.15)

[SOURCE: ISO 14083:2023, 3.1.25]

3.3.35

transport chain element

TCE

section of a transport chain within which the freight (3.3.3) or a (group of) passenger(s) is carried by a

single vehicle (3.3.10) or transits through a single hub (3.3.15)

EXAMPLE If a multimodal trip of a passenger includes taking a bus from stop “L4” to stop “L7” of bus line “L”,

then one TCE is the trip of the passenger from “L4” to “L7”.

[SOURCE: ISO 14083:2023, 3.1.26]

3.3.36

transport distance

distance between the origin and the destination of a passenger, a consignment or a vehicle (3.3.10) along

a specified route

Note 1 to entry: For the use of this document, the route followed by the passenger, the freight (3.3.3) or the vehicle

(3.3.10) may be different from that originally planned. This leads to two categories of transport distances: actual

distances, and distances used for calculation of greenhouse gas emissions (3.1.12), i.e. transport activity distances

(3.3.33)

[SOURCE: ISO 14083:2023, 3.1.27]

3.3.37

actual distance

transport distance along the actual route taken by a vehicle (3.3.10)

EXAMPLE Distance measured by an on-board device (odometer).

[SOURCE: ISO 14083:2023, 3.1.27.1]

3.3.38

transport operation

operation of a vehicle (3.3.10) in order to transport passengers and/or freight (3.3.3)

EXAMPLE If a multimodal trip of a passenger includes taking a bus from stop “L4” to stop “L7” of bus line “L”,

this requires a transport operation being the operation of this bus on line “L”, from the first stop “L1” to the last

stop of this bus line.

Note 1 to entry: It includes cases where the destination is the same as the origin passing through other locations

on the way.

[SOURCE: ISO 14083:2023, 3.1.28]

3.3.39

transport operation category

TOC

group of transport operations (3.3.38) that share similar characteristics

Note 1 to entry: ISO 14083:2023, Annexes A-G contain recommendations for the characteristics used to specify

the TOCs for each transport mode.

[SOURCE: ISO 14083:2023, 3.1.29]

3.3.40

transport operator

entity that carries out transport operations (3.3.38) involving carriage of freight (3.3.3) or passengers,

or both

[SOURCE: ISO 14083:2023, 3.1.30]

3.3.41

transport packaging

tertiary packaging

distribution packaging

protective packaging

packaging (3.3.24) designed to contain one or more articles or packages, or bulk material, for the

purposes of transport, handling and/or distribution

Note 1 to entry: Transport packaging does not include road, rail, ship and air containers.

[SOURCE: ISO 14083:2023, 3.4.4]

3.3.42

transport service

service provided to a user for the transport of freight (3.3.3) from an origin to a destination

[SOURCE: ISO 14083:2023, 3.1.31]

3.3.43

twenty-foot equivalent unit

TEU

standard unit used to express a number of containers of various lengths and for describing the

capacities of container ships or terminals

[SOURCE: ISO 14083:2023, 3.1.34]

3.3.44

vehicle operation

deployment of a vehicle (3.3.10) to fully or partially provide a transport operation (3.3.38)

[SOURCE: ISO 14083:2023, 3.1.36]

3.4 Life Cycle Assessment

3.4.1

cut-off criteria

specification of the amount of material or energy flow (3.2.17) or the level of significance of greenhouse

gas emissions (3.1.12) associated with unit processes or the product system (3.2.3) to be excluded from

a CFP study

Note 1 to entry: “Energy flow” is defined in ISO 14040:2006, 3.13.

[SOURCE: ISO 14067:2018, 3.1.4.1]

3.4.2

evaluation

element within the life cycle interpretation phase intended to establish confidence in the results of the

life cycle assessment (3.4.5)

Note 1 to entry: Evaluation includes completeness check, sensitivity check, consistency check, and any other

validation that may be required according to the goal and scope definition of the study

[SOURCE: ISO 14040:2006]

3.4.3

fugitive emissions

emissions that are not physically controlled but result from the intentional or unintentional releases

(3.4.11) of GHGs (3.1.9)

Note 1 to entry: They commonly arise from the production, processing transmission storage and use of fuels and

other chemicals, often through joints, seals, packing, gaskets, etc.

[SOURCE: 2004 GHG protocol, Chapter 4.6]

3.4.4

life cycle

consecutive and interlinked stages related to a product, from raw material acquisition or generation

from natural resources to end-of-life treatment

Note 1 to entry: “Raw material” is defined in ISO 14040:2006, 3.15.

Note 2 to entry: Stages of a life cycle related to a product include raw material acquisition, production,

distribution, use and end-of-life treatment.

[SOURCE: ISO 14067:2018, 3.1.4.2]

3.4.5

life cycle assessment

LCA

compilation and evaluation of the inputs, outputs and the potential environmental impacts of a product

system (3.2.3) throughout its life cycle (3.4.4)

Note 1 to entry: “Environmental impact” is defined in ISO 14001:2015, 3.2.4.

[SOURCE: ISO 14067:2018, 3.1.4.3]

3.4.6

life cycle inventory analysis

LCI

phase of life cycle assessment (3.4.5) involving the compilation and quantification of inputs (3.2.8) and

outputs (3.2.10) for a product throughout its life cycle (3.4.4)

[SOURCE: ISO 14044:2006, 3.3]

3.4.7

location-based method

uses the average emissions intensity of the electricity grid in the location in which energy consumption

occurs.

[SOURCE: ISO 14064-1:2018, Annex E]

3.4.8

market-based method

uses the emissions intensity from choices a consumer makes regarding its electricity supplier or

product

Note 1 to entry: These choices (purchasing energy certificates or differentiated electricity product) are reflected

through contractual arrangements between the purchaser and the provider.

[SOURCE: ISO 14064-1:2018, Annex E]

3.4.9

leakage

loss of a product or service that results in changes in GHG emissions (3.1.12)

3.4.10

process emissions

emissions generated from manufacturing processes, such as the CO that arises from the breakdown of

calcium carbonate (CaCO ) during cement manufacture

Note 1 to entry: Not to be confused with combustion emissions.

[SOURCE: ISO 14064-1:2018, Annex B]

3.4.11

releases

emissions to air and discharges to water and soil

[SOURCE: ISO 14040:2006, 3.30]

3.4.12

sensitivity analysis

systematic procedures for estimating the effects of the choices made regarding methods and data on

the outcome of a CFP study (3.1.5)

[SOURCE: ISO 14067:2018, 3.1.4.7]

3.4.13

sensitivity check

process to determine whether the information obtained from a sensitivity analysis is relevant for

reaching the conclusions and for giving recommendations

[SOURCE: ISO 14040:2006/AMD1: 2020, 3.43]

3.4.14

transparency

open, comprehensive and understandable presentation of information

[SOURCE: ISO 14040:2006, 3.7]

3.4.15

uncertainty analysis

systematic procedure to quantify the uncertainty introduced in the results of a life cycle

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...