SIST EN 15534-1:2014+A1:2018

(Main)Composites made from cellulose-based materials and thermoplastics (usually called wood-polymer composites (WPC) or natural fibre composites (NFC)) - Part 1: Test methods for characterisation of compounds and products

Composites made from cellulose-based materials and thermoplastics (usually called wood-polymer composites (WPC) or natural fibre composites (NFC)) - Part 1: Test methods for characterisation of compounds and products

This European Standard specifies test methods for the determination of properties of composites made from cellulose-based materials and thermoplastics, usually called wood-polymer composites (WPC) or natural fibre composites (NFC).

NOTE For editorial reasons, in EN 15534 the abbreviation "WPC" is used for ecomposites made from cellulose-based materials and thermoplastics.

This part of EN 15534 is applicable to cellular or non-cellular compounds and products, made from cellulose-based materials and thermoplastics, intended to be or being processed through plastics processing techniques, without threshold for the cellulose-based material content.

All the properties listed in this part of EN 15534 are not necessarily assessed for a given application. Test parameters and requirements of the test methods for a given application are specified in the relevant part of EN 15534.

Profiles for the management of electrical power cables, communication cables and power track systems used for the distribution of electrical power, profiles for windows or doors and profiles for guttering are not covered by EN 15534).

Verbundwerkstoffe aus cellulosehaltigen Materialien und Thermoplasten (üblicherweise Holz-Polymer-Werkstoffe (WPC) oder Naturfaserverbundwerkstoffe (NFC) genannt) - Teil 1: Prüfverfahren zur Beschreibung von Compounds und Erzeugnissen

Diese Europäische Norm legt Prüfverfahren fest zur Bestimmung der Eigenschaften von Verbundwerkstoffen aus cellulosehaltigen Materialien und Thermoplasten, üblicherweise Holz-Polymer-Werkstoffe (WPC, en: wood-polymer composites) oder Naturfaserverbundwerkstoffe (NFC, en: natural fibre composites) genannt.

ANMERKUNG 1 Aus redaktionellen Gründen wird in EN 15534 die Abkürzung „WPC“ für „Verbundwerkstoffe aus Cellulose haltigen Materialien und Thermoplasten“ verwendet.

Dieser Teil von EN 15534 gilt für geschäumte oder nicht geschäumte Compounds und Erzeugnisse, die aus cellulosehaltigen Materialien und Thermoplasten hergestellt sind, die durch plastische Verarbeitungsverfahren hergestellt wurden oder dafür vorgesehen sind, ohne Beschränkung für den Anteil an cellulosehaltigen Materialien.

Für eine bestimmte Verwendung brauchen nicht notwendigerweise alle in diesem Teil von EN 15534 aufgeführten Eigenschaften bewertet zu werden. Die Prüfverfahren und Anforderungen sind in dem entsprechenden Teil von EN 15534 festgelegt.

ANMERKUNG 2 Für Anwendungen in tragenden Konstruktionen, sind in CEN/TS 15534 2 [1] Modifikationsbeiwerte der Biegeeigenschaften von Profilen festgelegt.

Profile, die zur Verlegung von Stromkabeln, Kommunikationskabeln und Stromschienensystemen für die Verteilung von Strom verwendet werden, Profile für Fenster oder Türen und Profile für Regenrinnen werden in EN 15534 ) nicht behandelt.

Composites à base de matières cellulosiques et de thermoplastiques (communément appelés composites bois-polymères (WPC) ou composites fibres d'origine naturelle (NFC)) - Partie 1: Méthodes d'essai pour la caractérisation des compositions et des produits

La présente Norme européenne spécifie les méthodes d'essai pour la détermination des propriétés des composites à base de matières cellulosiques et de thermoplastiques, communément appelés composites bois-polymères (WPC) ou composites fibres d'origine naturelle (NFC).

NOTE Pour des raisons éditoriales, dans l'EN 15534, l'abréviation « WPC » est utilisée pour « composites à base de matières cellulosiques et de thermoplastiques ».

La présente partie de l’EN 15534 s'applique aux compositions et produits expansés ou non expansés à base de matières cellulosiques et de thermoplastiques, destinés à être fabriqués ou fabriqués au moyen de techniques de transformation des plastiques, sans seuil pour la teneur en matières cellulosiques.

Il n'est pas nécessairement requis pour une application donnée d'évaluer toutes les propriétés énumérées dans la présente partie de l'EN 15534. Les paramètres d'essai et les exigences relatives aux méthodes d'essai pour une application donnée sont spécifiés dans la partie pertinente de l'EN 15534.

L'EN 15534 ne traite pas des profilés pour la gestion des câbles d'énergie électrique, des câbles de communication et des systèmes de conducteurs préfabriqués utilisés pour la distribution de l'énergie électrique, des profilés pour les fenêtres ou les portes ni des profilés pour gouttières ).

Kompoziti iz materialov na osnovi celuloze in plastomerov (navadno imenovani lesno-polimerni kompoziti (WPC) ali kompoziti iz naravnih vlaken (NFC)) - 1. del: Preskusne metode za karakterizacijo spojin in proizvodov

Ta evropski standard določa preskusne metode za ugotavljanje lastnosti kompozitov iz materialov na osnovi celuloze in plastomerov, običajno imenovanih lesno-polimerni kompoziti (WPC) ali kompoziti iz naravnih vlaken (NFC).

OPOMBA: Zaradi uredniških razlogov se v standardu EN 15534 kratica »WPC« uporablja za kompozite iz materialov na osnovi celuloze in plastomere.

Ta del standarda EN 15534 se uporablja za celulozne ali necelulozne spojine in proizvode iz materialov na osnovi celuloze in plastomerov, ki so namenjeni za obdelavo ali so obdelani s tehnikami za obdelavo plastike, brez omejitve za vsebnost materialov na osnovi celuloze.

Za posamezen primer uporabe ni treba nujno oceniti vseh lastnosti, navedenih v tem delu standarda EN 15534. Preskusni parametri in zahteve preskusnih metod za posamezen primer uporabe so navedeni v ustreznem delu standarda EN 15534.

Profili za razvrščanje električnih napajalnih kablov, komunikacijskih kablov in napajalnih tračnih sistemov, ki se uporabljajo za distribucijo električne energije, profili za okna ali vrata in profili za žlebove niso zajeti v standardu EN 15534.

General Information

- Status

- Published

- Publication Date

- 18-Dec-2017

- Technical Committee

- IPMA - Polimer materials and products

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 09-Nov-2017

- Due Date

- 14-Jan-2018

- Completion Date

- 19-Dec-2017

Relations

- Effective Date

- 30-Aug-2017

- Effective Date

- 30-Aug-2017

Overview

EN 15534-1:2014+A1:2017 is the CEN European standard that specifies test methods for characterising composites made from cellulose‑based materials and thermoplastics-commonly called wood‑polymer composites (WPC) or natural fibre composites (NFC). This Part 1 document defines how to prepare specimens, condition samples and perform laboratory tests to determine physical, mechanical, durability and thermal properties of both cellular and non‑cellular compounds and finished products intended to be processed by plastics techniques. There is no minimum cellulose content threshold in scope. Note: some profile applications (electrical cable management, windows/doors, guttering) are excluded from EN 15534.

Key topics and technical requirements

The standard covers a wide range of measurable properties and associated test methods, including:

- Specimen preparation and conditioning (reference conditioning, factory control, third‑party testing)

- Physical properties: appearance, density, moisture content, slipperiness (pendulum & inclination tests), dimensional characteristics and linear mass for profiles

- Mechanical properties: impact resistance (including falling mass for products), tensile and flexural properties, creep behaviour, indentation resistance, nail/screw withdrawal and pull‑through resistance

- Durability: artificial weathering, natural ageing, moisture resistance (swelling, cyclic and boiling tests), resistance to biological agents (fungi, termites, algae), and salt spray

- Thermal properties: heat deflection temperature (HDT), linear thermal expansion, heat reversion, heat build‑up, and fire reaction tests (single flame and SBI where applicable)

- Other tests: degree of chalking, gloss change, peel strength for laminated profiles

The standard emphasises that not all tests are mandatory for every application; relevant properties and acceptance criteria are specified in the application‑specific parts of EN 15534.

Practical applications

EN 15534-1 is used to:

- Support product development and material formulation for WPC/NFC compounds

- Define quality control procedures and factory production control tests

- Provide consistent laboratory test methods for comparative performance evaluation

- Demonstrate durability and safety (e.g., reaction to fire, biological resistance) for market acceptance

- Supply data for design decisions (creep, mechanical strength, thermal expansion) and compliance documentation

Who should use this standard

- WPC/NFC manufacturers and compound formulators

- Independent testing laboratories and certification bodies

- Product designers, specifiers and engineers

- Procurement and quality assurance teams seeking standardized performance data

- Regulatory and standards organizations referencing harmonized test methods

Related standards

- Other parts of EN 15534 (application‑specific test parameters and requirements)

- Relevant ISO, EN and national standards referenced within EN 15534‑1 for specific test procedures

Keywords: EN 15534-1, wood‑polymer composites, WPC, natural fibre composites, NFC, test methods, characterisation, durability, mechanical properties, thermal properties, CEN.

Frequently Asked Questions

SIST EN 15534-1:2014+A1:2018 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Composites made from cellulose-based materials and thermoplastics (usually called wood-polymer composites (WPC) or natural fibre composites (NFC)) - Part 1: Test methods for characterisation of compounds and products". This standard covers: This European Standard specifies test methods for the determination of properties of composites made from cellulose-based materials and thermoplastics, usually called wood-polymer composites (WPC) or natural fibre composites (NFC). NOTE For editorial reasons, in EN 15534 the abbreviation "WPC" is used for ecomposites made from cellulose-based materials and thermoplastics. This part of EN 15534 is applicable to cellular or non-cellular compounds and products, made from cellulose-based materials and thermoplastics, intended to be or being processed through plastics processing techniques, without threshold for the cellulose-based material content. All the properties listed in this part of EN 15534 are not necessarily assessed for a given application. Test parameters and requirements of the test methods for a given application are specified in the relevant part of EN 15534. Profiles for the management of electrical power cables, communication cables and power track systems used for the distribution of electrical power, profiles for windows or doors and profiles for guttering are not covered by EN 15534).

This European Standard specifies test methods for the determination of properties of composites made from cellulose-based materials and thermoplastics, usually called wood-polymer composites (WPC) or natural fibre composites (NFC). NOTE For editorial reasons, in EN 15534 the abbreviation "WPC" is used for ecomposites made from cellulose-based materials and thermoplastics. This part of EN 15534 is applicable to cellular or non-cellular compounds and products, made from cellulose-based materials and thermoplastics, intended to be or being processed through plastics processing techniques, without threshold for the cellulose-based material content. All the properties listed in this part of EN 15534 are not necessarily assessed for a given application. Test parameters and requirements of the test methods for a given application are specified in the relevant part of EN 15534. Profiles for the management of electrical power cables, communication cables and power track systems used for the distribution of electrical power, profiles for windows or doors and profiles for guttering are not covered by EN 15534).

SIST EN 15534-1:2014+A1:2018 is classified under the following ICS (International Classification for Standards) categories: 79.080 - Semi-manufactures of timber; 83.140.99 - Other rubber and plastics products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15534-1:2014+A1:2018 has the following relationships with other standards: It is inter standard links to SIST EN 15534-1:2014, SIST EN 15534-1:2014/oprA1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase SIST EN 15534-1:2014+A1:2018 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kompoziti iz materialov na osnovi celuloze in plastomerov (navadno imenovani lesno-polimerni kompoziti (WPC) ali kompoziti iz naravnih vlaken (NFC)) - 1. del: Preskusne metode za karakterizacijo spojin in proizvodovVerbundwerkstoffe aus cellulosehaltigen Materialien und Thermoplasten (üblicherweise Holz-Polymer-Werkstoffe (WPC) oder Naturfaserverbundwerkstoffe (NFC) genannt) - Teil 1: Prüfverfahren zur Beschreibung von Compounds und ErzeugnissenComposites à base de matières cellulosiques et de thermoplastiques (communément appelés composites bois-polymères (WPC) ou composites fibres d'origine naturelle (NFC)) - Partie 1: Méthodes d'essai pour la caractérisation des compositions et des produitsComposites made from cellulose-based materials and thermoplastics (usually called wood-polymer composites (WPC) or natural fibre composites (NFC)) - Part 1: Test methods for characterisation of compounds and products83.140.99Drugi izdelki iz gume in polimernih materialovOther rubber and plastics products79.080Polizdelki iz lesaSemi-manufactures of timberICS:Ta slovenski standard je istoveten z:EN 15534-1:2014+A1:2017SIST EN 15534-1:2014+A1:2018en,fr,de01-februar-2018SIST EN 15534-1:2014+A1:2018SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15534-1:2014+A1

November

t r s y ICS

y {ä r z râ

z uä r z rä r sâ

z uä s v rä { { Supersedes EN

s w w u væ sã t r s vEnglish Version

Composites made from celluloseæbased materials and methods for characterisation of compounds and productsComposites à base de matières cellulosiques et de caractérisation des compositions et des produits

Verbundwerkstoffe aus cellulosehaltigen Materialien Beschreibung von Compounds und Erzeugnissen This European Standard was approved by CEN on

{ November

t r s u and includes Amendment

s approved by CEN on

{ August

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s y CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s w w u væ sã t r s v ªA sã t r s y ESIST EN 15534-1:2014+A1:2018

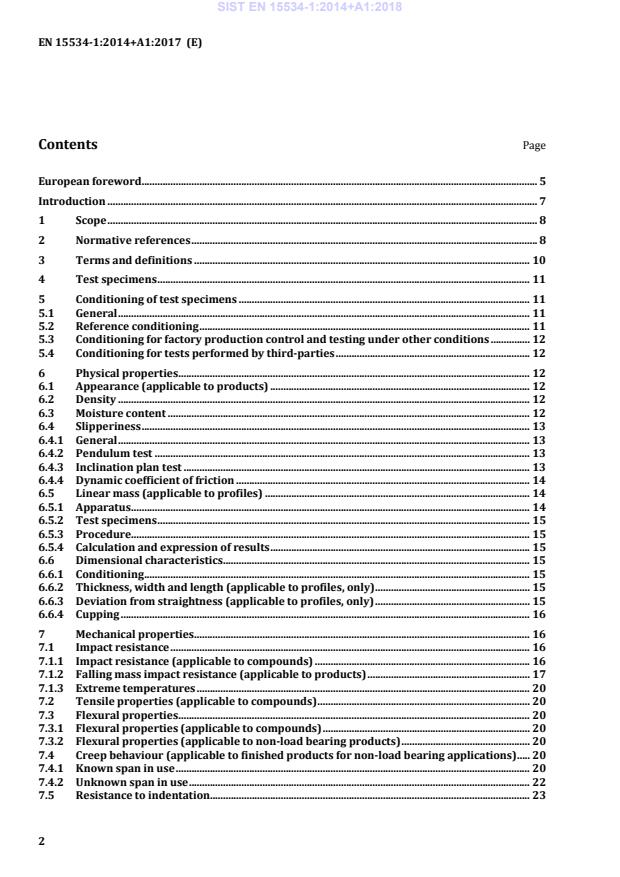

(E) 2 Contents Page European foreword . 5 Introduction . 7 1 Scope . 8 2 Normative references . 8 3 Terms and definitions . 10 4 Test specimens . 11 5 Conditioning of test specimens . 11 5.1 General . 11 5.2 Reference conditioning . 11 5.3 Conditioning for factory production control and testing under other conditions . 12 5.4 Conditioning for tests performed by third-parties . 12 6 Physical properties . 12 6.1 Appearance (applicable to products) . 12 6.2 Density . 12 6.3 Moisture content . 12 6.4 Slipperiness . 13 6.4.1 General . 13 6.4.2 Pendulum test . 13 6.4.3 Inclination plan test . 13 6.4.4 Dynamic coefficient of friction . 14 6.5 Linear mass (applicable to profiles) . 14 6.5.1 Apparatus . 14 6.5.2 Test specimens . 15 6.5.3 Procedure. 15 6.5.4 Calculation and expression of results . 15 6.6 Dimensional characteristics. 15 6.6.1 Conditioning . 15 6.6.2 Thickness, width and length (applicable to profiles, only) . 15 6.6.3 Deviation from straightness (applicable to profiles, only) . 15 6.6.4 Cupping . 16 7 Mechanical properties . 16 7.1 Impact resistance . 16 7.1.1 Impact resistance (applicable to compounds) . 16 7.1.2 Falling mass impact resistance (applicable to products) . 17 7.1.3 Extreme temperatures . 20 7.2 Tensile properties (applicable to compounds) . 20 7.3 Flexural properties . 20 7.3.1 Flexural properties (applicable to compounds) . 20 7.3.2 Flexural properties (applicable to non-load bearing products) . 20 7.4 Creep behaviour (applicable to finished products for non-load bearing applications) . 20 7.4.1 Known span in use . 20 7.4.2 Unknown span in use . 22 7.5 Resistance to indentation. 23 SIST EN 15534-1:2014+A1:2018

(E) 4 10.3.6 Test report . 49 Annex A (normative)

Determination of the modulus of elasticity in bending and bending strength of profiles . 51 A.1 Principle . 51 A.2 Apparatus . 51 A.3 Test specimens . 52 A.4 Atmosphere for conditioning and testing . 53 A.5 Procedure. 53 A.6 Expression of results . 54 A.6.1 Modulus of elasticity in bending . 54 A.6.2 Bending strength . 56 A.7 Test report . 57 Bibliography . 59

1) In preparation. SIST EN 15534-1:2014+A1:2018

(E) 6 — prEN 15534-7, Composites made from cellulose-based materials and thermoplastics (usually called wood-polymer composites (WPC) or natural fibre composites (NFC)) — Part 7: Specifications for general purpose profiles in external applications1) According to the CEN-CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 15534-1:2014+A1:2018

(E) 8 1 Scope This European Standard specifies test methods for the determination of properties of composites made from cellulose-based materials and thermoplastics, usually called wood-polymer composites (WPC) or natural fibre composites (NFC). NOTE

For editorial reasons, in EN 15534 the abbreviation “WPC” is used for “composites made from cellulose-based materials and thermoplastics”. This part of EN 15534 is applicable to cellular or non-cellular compounds and products, made from cellulose-based materials and thermoplastics, intended to be or being processed through plastics processing techniques, without threshold for the cellulose-based material content. All the properties listed in this part of EN 15534 are not necessarily assessed for a given application. Test parameters and requirements of the test methods for a given application are specified in the relevant part of EN 15534. Profiles for the management of electrical power cables, communication cables and power track systems used for the distribution of electrical power, profiles for windows or doors and profiles for guttering are not covered by EN 155342). 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 84:1997, Wood preservatives - Accelerated ageing of treated wood prior to biological testing - Leaching procedure EN 117:2012, Wood preservatives - Determination of toxic values against Reticulitermes species (European termites) (Laboratory method) EN 152:2011, Wood preservatives - Determination of the protective effectiveness of a preservative treatment against blue stain in wood in service - Laboratory method EN 317, Particleboards and fibreboards - Determination of swelling in thickness after immersion in water EN 321:2001, Wood-based panels - Determination of moisture resistance under cyclic test conditions EN 322:1993, Wood-based panels - Determination of moisture content EN 477:1995, Unplasticized polyvinylchloride (PVC-U) profiles for the fabrication of windows and doors - Determination of the resistance to impact of main profiles by falling mass EN 479, Unplasticized polyvinylchloride (PVC-U) profiles for the fabrication of windows and doors - Determination of heat reversion EN 927-3, Paints and varnishes - Coating materials and coating systems for exterior wood - Part 3: Natural weathering test

2) Profiles that are excluded are in the scopes of standards prepared by CEN/TC 33, CENELEC/TC 213 or CEN/TC 128. SIST EN 15534-1:2014+A1:2018

(E) 10 EN ISO 2813, Paints and varnishes - Determination of specular gloss of non-metallic paint films at 20°, 60° and 85° (ISO 2813) EN ISO 4589-2, Plastics - Determination of burning behaviour by oxygen index - Part 2: Ambient-temperature test (ISO 4589-2) EN ISO 4628-6, Paints and varnishes - Evaluation of degradation of coatings - Designation of quantity and size of defects, and of intensity of uniform changes in appearance - Part 6: Assessment of degree of chalking by tape method (ISO 4628-6) EN ISO 4892-2:2013, Plastics - Methods of exposure to laboratory light sources - Part 2: Xenon-arc lamps (ISO 4892-2:2013) EN ISO 9227, Corrosion tests in artificial atmospheres - Salt spray tests (ISO 9227) EN ISO 9239-1, Reaction to fire tests for floorings - Part 1: Determination of the burning behaviour using a radiant heat source (ISO 9239-1) !EN ISO 11664-1, Colorimetry — Part 1: CIE standard colorimetric observers (ISO 11664-1)" !EN ISO 11664-2, Colorimetry — Part 2: CIE standard illuminants (ISO 11664-2)" !EN ISO 11664-4, Colorimetry — Part 4: CIE 1976 L*a*b* Colour space (ISO 11664-4)" EN ISO 11925-2, Reaction to fire tests - Ignitability of products subjected to direct impingement of flame - Part 2: Single-flame source test (ISO 11925-2) !EN ISO 16474-3:2013, Paints and varnishes - Methods of exposure to laboratory light sources — Part 3: Fluorescent UV lamps (ISO 16474-3:2013)" ISO 11359-2, Plastics - Thermomechanical analysis (TMA) - Part 2: Determination of coefficient of linear thermal expansion and glass transition temperature ISO 16869, Plastics - Assessment of the effectiveness of fungistatic compounds in plastics formulations !ISO 18314-1, Analytical colourimetry — Part 1: Practical colour measurement" ASTM D3273–00(2005), Standard Test Method for resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber CIE3) Publication 51, A method for assessing the quality of daylight simulators for colorimetry 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 472:2013 and the following apply.

3) Commission internationale de l'éclairage, Central Bureau, Kegelgasse 27, A-1030, Vienna, Austria. SIST EN 15534-1:2014+A1:2018

(E) 12 The atmosphere 20/65 (20 °C, 65 % RH) may also be used. In that case, these conditions shall be declared in the test report. Constant mass is considered to be reached when the results of two successive weighing operations, carried out at an interval of 24 h, do not differ by more than 0,1 % (arithmetic mean value) determined on the basis of the mass of the cellulosic material present in the WPC material. If the content of cellulosic material is not known, it shall be determined using a suitable method. If the tested material contains a matrix polymer which itself absorbs water (e.g. starch), the mass of the respective matrix polymer shall be added to the mass of the cellulosic material. If the time until constant mass is reached is considered excessively long, the change in mass of the specimens shall be monitored and recorded over a period of 96 h by taking at least four measurements. Tests are conducted after conditioning for at least 96 h and the moisture content at the time of testing shall be determined according to 6.3 and stated. The content of cellulosic material of the WPC material shall be stated. For each test method, the moisture content of one additional test specimen shall be determined according to 6.3 before testing and shall be declared in the test report. NOTE It is most probable that the moisture equilibrium of the material is not reached but the product is assumed to be suitable for testing. 5.3 Conditioning for factory production control and testing under other conditions For the purpose of factory production control and testing under other conditions, the conditioning shall be carried out according to the specifications defined by the manufacturer. The conditioning parameters and tolerances shall be documented. 5.4 Conditioning for tests performed by third-parties In the case where the tests are performed in a test laboratory of a third party, the tests should be started from the fourth week and not later than the sixth week after the production date of the specimens. The specimens shall be stored under conditions specified in 5.2, except during the transport. 6 Physical properties 6.1 Appearance (applicable to products) The surfaces of the specimens shall illuminated by a source that complies with the CIE standard illuminant D65 (see CIE Publication No. 51) with an illumination of at least 600 lx. The light is incident upon the surfaces at an angle of approximately 45°, and the direction of viewing is approximately along the perpendicular to the plane of the surfaces. 6.2 Density The density of WPC materials shall be determined according to either EN ISO 1183-1 [Method A (immersion method), or Method C (titration method)] or EN ISO 1183-3. For solid profiles, the density of WPC materials may also be determined according to EN 323 [1]. 6.3 Moisture content The moisture content of WPC materials shall be determined according to EN 322:1993 with the following change in 5.2. SIST EN 15534-1:2014+A1:2018

(E) 14 6.4.3.6 Test specimen The test specimen is a surface of at least 1 000 mm in length and 500 mm in width. Components of irregular shape shall be placed on aside the other, as nearby as possible, to cover the test surface of 1 000 mm x 500 mm. The number of test specimens shall be as specified in the reference standard. 6.4.3.7 Test method The test specimen is mounted and centred on the flat plate of the test rig. During the whole test, the test specimen shall be continuously and regularly wetted with a least 5 l/min of the test liquid. If the fugues develop mainly in a specific direction, the specimen shall be tested in this direction and at a 90° angle. The test person moves half the length of a step forwards and backwards in an upright position, looking down to the test specimen surface, in a downstream direction. At the same time, the inclination of the test rig is increased by about 1° per second, starting from a horizontal position. The angle of inclination causing the test person to feel insecure shall be established through repeated changes of the inclination of the rig around the critical value. 6.4.3.8 Evaluation The test results are expressed according to three rating classes: — Class A: 12°: the items with a test result from 12° to 17°; — Class B: 18°: the items with a test result from 18° to 23°; — Class C: 24°: the items with a test result from 24° upwards. 6.4.3.9 Test report The test report shall include the following information: a) a reference to this subclause of EN 15534-1; b) all the information necessary for identification of the product tested; c) the angle of inclination and rating group. 6.4.4 Dynamic coefficient of friction The dynamic coefficient of friction on the surfaces of the product shall be determined according to EN 13893. 6.5 Linear mass (applicable to profiles) 6.5.1 Apparatus 6.5.1.1 Balance, with an accuracy of 0,1 g. 6.5.1.2 Rule or measuring tape, with an accuracy of 0,5 mm. SIST EN 15534-1:2014+A1:2018

is the value of the linear mass of the test specimen, expressed in grams per metre; M

is the mass of the test specimen, expressed in grams; L

is the length of the test specimen, expressed in metres. 6.6 Dimensional characteristics 6.6.1 Conditioning Condition the test specimens before measuring according to 5.2 or, for the purpose of factory production control, according to 5.3. 6.6.2 Thickness, width and length (applicable to profiles, only) The measurements of the thickness and width of a test specimen shall be carried out manually with an accuracy of 0,05 mm and the measurement of the length, with an accuracy of 1 mm. The number of test specimens shall be as specified in the reference standard. 6.6.3

Deviation from straightness (applicable to profiles, only) The test shall be carried out on the whole cross-section of the profile. The length of the test specimen shall be (1 000 ± 5) mm. The number of test specimens shall be as specified in the reference standard. The test specimen shall be tested in flatwise and edgewise positions. Place the test specimen with its concave side on a flat surface. Measure the gap(s) between the test specimen and the flat surface with an appropriate measuring device. Record the maximum value of the gap. SIST EN 15534-1:2014+A1:2018

(E) 16 6.6.4 Cupping Measure the cupping (flatness deviation across the width) of the test specimen by using a bow gauge placed at the position of greatest deformation. Use a bow gauge, the length of which is at minimum the width of the test specimen, graduated to allow a reading to 0,1 mm (see Figure 1).

Key 1 test specimen 2 bow gauge Figure 1 — Bow gauge for measuring cupping Place the test specimen concave side up without restraint on a flat horizontal surface. Place the bow gauge so that the three points (two fixed and one movable) are lightly touching the surface of the test specimen in the area of greatest deformation, and measure the flatness deviation (shown on the dial gauge) to the nearest 0,1 mm. The two fixed points shall be at 5 mm apart from the edges of the flat surface of the test specimen. The measured point shall correspond to the maximum bow. The measuring tip of the bow gauge shall have a diameter between 10 mm to 16 mm. The maximum flatness deviation measured using the bow gauge shall be recorded. The number of test specimens shall be as specified in the reference standard. 7 Mechanical properties 7.1 Impact resistance 7.1.1 Impact resistance (applicable to compounds) The Charpy impact strength of compound shall be determined according to EN ISO 179-1 by using Method ISO 179-1/1fU. SIST EN 1553

...

SIST EN 15534-1:2014+A1:2018 표준은 셀룰로오스 기반 재료와 열가소성 플라스틱으로 만들어진 복합재료의 특성을 결정하기 위한 시험 방법을 규정하고 있습니다. 이 표준의 범위는 일반적으로 목재-폴리머 복합재료(WPC) 또는 자연 섬유 복합재료(NFC)로 알려진 제품의 형성 및 특성 평가에 중점을 두고 있습니다. 이 표준의 강점은 셀룰로오스 기반 재료와 열가소성 플라스틱의 조합을 통해 다양한 응용 프로그램에 맞춘 테스트 방법을 제공함으로써, 복합재료의 성능을 일관되게 평가할 수 있다는 점입니다. 모든 무형의 또는 비무형의 복합재료와 제품에 적용 가능하며, 해당 표준은 공정에서 사용되는 재료의 비율에 대한 제한 없이 활용될 수 있습니다. 또한, EN 15534의 이 부분은 특정 응용 분야에 대한 시험 매개변수와 요구 사항을 명확히 규정하고 있어, 사용자가 필요한 성능의 특성을 정확히 파악하고 맞춤형 평가를 진행할 수 있도록 지원합니다. 이는 목재-폴리머 복합재료(WPC) 및 자연 섬유 복합재료(NFC)의 품질 보증과 신뢰성을 높이는 데 기여합니다. 그러나 주의할 점은 이 표준이 전기 전력 케이블, 통신 케이블 및 전력 트랙 시스템 관리에 관한 프로파일 또는 창문, 문, 배수구 프로파일과 같은 특정 제품에는 적용되지 않는다는 것입니다. 따라서 사용자는 자신의 응용 분야에 적합한 잣대와 평가 방법을 정확히 이해하기 위해 관련 표준의 다른 부분을 참조해야 합니다. 결론적으로, SIST EN 15534-1:2014+A1:2018 표준은 WPC와 NFC의 특성을 평가하는 데 있어 중요한 기준을 제시하며, 공정한 평가와 일관된 품질을 보장할 수 있는 중요한 도구로서 그 중요성이 더욱 강조됩니다.

La norme SIST EN 15534-1:2014+A1:2018 est un document essentiel qui définit des méthodes d'essai pour la caractérisation des composites fabriqués à partir de matériaux cellulosiques et de thermoplastiques, communément appelés composites bois-polymère (WPC) ou composites à base de fibres naturelles (NFC). Cette norme européenne est particulièrement pertinente dans le contexte actuel où la durabilité et l'utilisation de matériaux renouvelables sont au premier plan des préoccupations industrielles. Le champ d'application de cette norme couvre tant les composés cellulaires que non cellulaires, permettant ainsi une large utilisation dans diverses applications industrielles. En précisant que la norme est applicable aux composites sans seuil pour le contenu en matériau cellulosique, elle favorise l'innovation dans le développement de nouveaux produits. Cela ouvre la voie à des solutions qui répondent à la demande croissante pour des matériaux plus écologiques et durables. Parmi les forces de la norme SIST EN 15534-1:2014+A1:2018, on note la clarté dans la définition des méthodes d'essai qui sont essentielles pour évaluer les propriétés des composites. Cette clarté est cruciale pour les ingénieurs et les fabricants qui cherchent à garantir la qualité et la performance de leurs produits. De plus, la norme met en évidence que tous les paramètres de test ne seront pas nécessairement évalués pour chaque application, ce qui permet une flexibilité adaptée aux besoins spécifiques des utilisateurs tout en respectant les exigences de performance. La pertinence de cette norme dans le domaine des composites à base de cellulose et de thermoplastiques ne saurait être sous-estimée. Avec un marché en constante évolution, la normalisation des méthodes d'essai contribue à une meilleure compréhension des matériaux, facilite la certification et améliore la confiance des consommateurs dans les produits finis. En favorisant des pratiques de test standardisées, la norme SIST EN 15534-1:2014+A1:2018 représente un atout indéniable pour les professionnels travaillant avec des composites WPC et NFC dans leur quête d'innovation durable.

The SIST EN 15534-1:2014+A1:2018 standard presents a comprehensive framework for the characterization of composites made from cellulose-based materials and thermoplastics, commonly referred to as wood-polymer composites (WPC) or natural fibre composites (NFC). This European Standard encompasses a range of test methods designed to ascertain various properties of these innovative materials, signifying its relevance in the growing sector of sustainable composites. The scope of the standard is well-defined. It applies to both cellular and non-cellular compounds and products derived from cellulose-based materials and thermoplastics. One of the key strengths of this standard is its inclusive nature, allowing for the assessment of materials that may contain varying levels of cellulose-based content. This flexibility is crucial for manufacturers looking to explore different formulations without the constraints of minimum thresholds, thereby encouraging innovation within the industry. Furthermore, the standard provides detailed guidelines for the testing of specific properties, which are paramount in applications ranging from construction to consumer products. Although not all properties may be applicable to every application, the document allows users to select the relevant test parameters as specified in other sections of EN 15534. This targeted approach enables users to efficiently tailor testing protocols to meet their specific needs, enhancing the usability of the standard. While certain applications, such as profiles for electrical power cables and guttering systems, are explicitly excluded, the standard remains broadly applicable to a wide array of products made from WPC and NFC. This delineation suggests that the standard is focused on fostering the development and performance evaluation of composite materials in areas where they can deliver significant environmental benefits. In summary, SIST EN 15534-1:2014+A1:2018 stands out as a vital document for the characterization and testing of cellulose-based composites, addressing a critical need within the composite materials sector. Its robust scope, combined with practical test provisions, positions it as an essential resource for manufacturers and researchers aiming to enhance the sustainability and performance of wood-polymer and natural fibre composites.

Die Norm SIST EN 15534-1:2014+A1:2018 stellt einen bedeutenden Schritt in der Standardisierung von Verbundwerkstoffen dar, die aus zellulosehaltigen Materialien und Thermoplasten bestehen. Dieser Standard definiert spezifische Prüfmethoden zur Bestimmung der Eigenschaften von Verbundwerkstoffen, die gemeinhin als Holz-Kunststoff-Verbundstoffe (WPC) oder natürliche Faserverbundstoffe (NFC) bezeichnet werden. Ein hervorzuhebender Aspekt der Norm ist ihr umfassender Anwendungsbereich. Sie gilt sowohl für zellulare als auch für nicht-zellulare Verbindungen und Produkte, die aus zellulosehaltigen Materialien und Thermoplasten hergestellt werden. Dies ermöglicht eine breite Anwendung in verschiedenen Industrien, die sich mit Kunststoffverarbeitungstechniken beschäftigen. Durch die Offenheit für einen variablen Gehalt an zellulosehaltigen Materialien, ohne eine Mindestgrenze, ist diese Norm besonders relevant für die Entwicklung nachhaltiger Produkte, die ökologische Materialien in innovativen Anwendungen integrieren. Die Stärken der Norm liegen nicht nur in ihrer Flexibilität, sondern auch in der klaren Strukturierung der Prüfparameter und Anforderungen, die für spezifische Anwendungen angegeben werden. Dies erlaubt Herstellern eine zielgerichtete Qualitätssicherung und erleichtert den Marktzugang für neue Produkte, die den Normen entsprechen. Darüber hinaus hat die DIN EN 15534 eine wichtige Funktion für die Außenwahrnehmung und das Vertrauen in die Qualität von Holz-Kunststoff-Verbundstoffen und natürlichen Faserverbundstoffen geschaffen. Die standardisierte Prüfung der Eigenschaften und die klare Kommunikation über die Leistungsfähigkeit dieser Materialien fördert ihre Akzeptanz auf dem Markt und innerhalb der relevanten Branchen. Die Relevanz des Dokuments kann nicht hoch genug eingeschätzt werden, da es sowohl den Industrieakteuren als auch den Endverbrauchern eine sichere Basis für Entscheidungen bietet. Durch die Festlegung von Testmethoden, die streng und nachvollziehbar sind, stärkt die Norm das Vertrauen in die Qualität und Umweltverträglichkeit von WPC und NFC. Insgesamt bietet die SIST EN 15534-1:2014+A1:2018 eine solide Grundlage zur Charakterisierung von Verbundwerkstoffen und ist damit ein unverzichtbares Instrument für alle, die im Bereich der zellulosehaltigen Materialien und Thermoplasten tätig sind.

SIST EN 15534-1:2014+A1:2018は、セルロース系材料と熱可塑性樹脂から製造される複合材料の特性を評価するための試験方法を規定した欧州標準です。この標準は、一般に木質ポリマー複合材(WPC)または自然繊維複合材(NFC)と呼ばれ、さまざまなセルロース系材料と熱可塑性樹脂によって作られた化合物や製品に適用されます。 この標準の強みは、セルロース系材料の内容量に制限なしに、プラスチック加工技術を通じて処理されることを意図した製品のすべての特性を適切に試験できる点にあります。SIST EN 15534-1は、さまざまな応用に関連する試験パラメータおよび要求事項も明確に示しており、利用者が必要とする情報を簡単に取得できるようになっています。 さらに、この標準は、セルロース系材料と熱可塑性樹脂からの複合材料の特性を明確に定義しており、特に現在の持続可能な素材の需要が高まる中、WPCやNFCの重要性が増していることに貢献しています。試験方法の明瞭化は、製品の品質向上に寄与し、市場での競争力を高める要素となるでしょう。 このように、SIST EN 15534-1:2014+A1:2018は、WPCおよびNFCに関する試験方法を包括的に規定し、これらの素材の特性評価において不可欠な標準であり、製造業者や研究者にとって重要な参考資料となります。この標準を用いることで、製品のとりうる特性を把握し、適切な品質管理を行うことが可能になります。全体として、SIST EN 15534-1は、セルロース系素材を用いた持続可能な製品開発のための基盤を提供する重要な標準といえます。

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...