SIST EN 17666:2023

(Main)Maintenance - Maintenance engineering - Requirements

Maintenance - Maintenance engineering - Requirements

This document specifies the maintenance engineering discipline throughout the entire life cycle.

This document gives guidance on how maintenance engineering can contribute to the assurance of required dependability to achieve a sustainable balance between performance, risk and costs.

This document refers to standards that further describe detailed methods and techniques.

This document does not give guidance on how to set up systems and infrastructure for maintenance engineering nor does it include guidance on software maintenance.

NOTE 1 For software components of an item, the maintenance activities are covered in ISO/IEC/IEEE 14764 [54].

NOTE 2 The overall maintenance process is covered by EN 17007 [10].

Instandhaltung - Instandhaltungsengineering - Anforderungen

Dieses Dokument legt die Disziplin des Instandhaltungsengineerings über den gesamten Lebenszyklus fest.

Dieses Dokument enthält Anleitungen dazu, wie das Instandhaltungsengineering zur Sicherstellung der geforderten Funktionssicherheit beitragen kann, um einen nachhaltigen Ausgleich zwischen Leistung, Risiko und Kosten zu erreichen.

Dieses Dokument verweist auf Normen, in denen detaillierte Methoden und Techniken ausführlicher beschrieben werden.

Dieses Dokument enthält keine Anleitungen dazu, wie Instandhaltungsengineering-Systeme und Infrastruktur zu erstellen sind, noch enthält es Anleitungen für die Instandhaltung von Software.

ANMERKUNG 1 Die Instandhaltungstätigkeiten für die Softwarekomponenten eines Objekts werden in ISO/IEC/IEEE 14764 [54] behandelt.

ANMERKUNG 2 Der allgemeine Instandhaltungsprozess wird in EN 17007 [10] behandelt.

Maintenance - Ingénierie de maintenance - Exigences

Le présent document spécifie la discipline d’ingénierie de maintenance tout au long du cycle de vie.

Il fournit également des recommandations sur la façon dont l’ingénierie de maintenance peut contribuer à assurer la sûreté de fonctionnement requise afin d’établir un équilibre durable entre performances, risques et coûts.

Le présent document se réfère à des normes qui décrivent plus en détail les méthodes et techniques concernées.

Il ne fournit aucune recommandation pour la mise en place de systèmes et d’infrastructure pour l’ingénierie de maintenance, ni aucune recommandation sur la maintenance des logiciels.

NOTE 1 Pour les composants logiciels d’un bien, les activités de maintenance sont traitées dans l’ISO/IEC/IEEE 14764 [54].

NOTE 2 Le processus global de maintenance est couvert par l’EN 17007 [10].

Vzdrževanje - Vzdrževalni inženiring - Zahteve

Ta dokument opisuje splošna načela, merila in vsebino vzdrževalnega inženiringa. To vključuje smernice za metode in tehnike, ki se uporabljajo za vzdrževanje zahtevanih funkcij elementov v kateri koli fazi njihovega življenjskega cikla.

Ta dokument podaja smernice o tem, kako lahko vzdrževalni inženiring prispeva k zagotavljanju zahtevane celovitosti, varnosti, zanesljivosti in vzdrževanja, da se doseže trajnostno ravnovesje med zmogljivostjo, tveganjem in stroški.

Ta dokument se navezuje na standarde, ki podrobneje opisujejo metode in tehnike.

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Jun-2021

- Publication Date

- 27-Dec-2022

- Technical Committee

- VZD - Maintenance

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 07-Dec-2022

- Due Date

- 11-Feb-2023

- Completion Date

- 28-Dec-2022

Overview

EN 17666:2022 - Maintenance engineering - Requirements (CEN) defines the maintenance engineering discipline across the entire life cycle of physical assets. It provides generic, non-prescriptive guidance on how maintenance engineering contributes to assuring required dependability, balancing performance, risk and costs, and applying sustainability principles. The standard applies to maintenance engineering activities from concept through disposal/transition and references more detailed methods in related standards.

Key topics and requirements

- Life‑cycle focus: Maintenance engineering activities are described for these stages - concept, development (preliminary and detailed design), realization (build, implementation/commissioning), utilization (operation and maintenance) and disposal/transition (reuse, recycling, disposal).

- Dependability and risk: Guidance on influencing design and performing risk analysis to achieve required reliability, availability, maintainability and safety objectives.

- Maintainability and design influence: Emphasis on design-for-maintainability practices and analyses (see informative Annex C) to reduce life‑cycle costs and environmental footprint.

- Techniques and analyses: Informative guidance on applicable techniques, analyses and practices (Annex B) to support maintenance engineering work.

- Integrated logistic support (ILS): Relationship between maintenance engineering and ILS is described in Annex A to align supportability and logistic planning.

- Digitalization: Clause 7 addresses digitalization requirements and how digital tools and data support maintenance engineering across the life cycle.

- Scope limits: EN 17666 does not prescribe infrastructure or organizational systems setup for maintenance engineering and it excludes software maintenance (software components are covered by ISO/IEC/IEEE 14764). The overall maintenance process is addressed by EN 17007.

Practical applications and who uses it

EN 17666 is intended for personnel involved in:

- Asset owners and operators aiming to define maintenance requirements and optimize life‑cycle performance

- Design and engineering teams integrating maintainability and supportability requirements early in product/system design

- Maintenance planners and reliability engineers assessing risk, maintainability and life‑extension decisions

- Procurement and contract managers specifying maintenance-related deliverables and warranties

- Maintenance service providers aligning technical support with dependability objectives

Practical uses include shaping maintenance requirements during concept and design, guiding maintainability assessments, informing logistic support analyses, and defining digital data needs for condition‑based maintenance.

Related standards

- EN 17007 - Overall maintenance process

- EN 13306 - Maintenance terminology

- ISO/IEC/IEEE 14764 - Software maintenance (for software components)

- ISO 55000 series and IEC 60300 series - Asset management and dependability context

Keywords: EN 17666:2022, maintenance engineering, dependability, life cycle, maintainability, asset management, maintenance standards, CEN.

Frequently Asked Questions

SIST EN 17666:2023 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Maintenance - Maintenance engineering - Requirements". This standard covers: This document specifies the maintenance engineering discipline throughout the entire life cycle. This document gives guidance on how maintenance engineering can contribute to the assurance of required dependability to achieve a sustainable balance between performance, risk and costs. This document refers to standards that further describe detailed methods and techniques. This document does not give guidance on how to set up systems and infrastructure for maintenance engineering nor does it include guidance on software maintenance. NOTE 1 For software components of an item, the maintenance activities are covered in ISO/IEC/IEEE 14764 [54]. NOTE 2 The overall maintenance process is covered by EN 17007 [10].

This document specifies the maintenance engineering discipline throughout the entire life cycle. This document gives guidance on how maintenance engineering can contribute to the assurance of required dependability to achieve a sustainable balance between performance, risk and costs. This document refers to standards that further describe detailed methods and techniques. This document does not give guidance on how to set up systems and infrastructure for maintenance engineering nor does it include guidance on software maintenance. NOTE 1 For software components of an item, the maintenance activities are covered in ISO/IEC/IEEE 14764 [54]. NOTE 2 The overall maintenance process is covered by EN 17007 [10].

SIST EN 17666:2023 is classified under the following ICS (International Classification for Standards) categories: 03.080.10 - Maintenance services. Facilities management. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase SIST EN 17666:2023 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2023

Vzdrževanje - Vzdrževalni inženiring - Zahteve

Maintenance - Maintenance engineering - Requirements

Instandhaltung - Instandhaltungsengineering - Anforderungen

Maintenance - Ingénierie de maintenance - Exigences

Ta slovenski standard je istoveten z: EN 17666:2022

ICS:

03.080.10 Vzdrževalne storitve. Maintenance services.

Upravljanje objektov Facilities management

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17666

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2022

EUROPÄISCHE NORM

ICS 03.080.10

English Version

Maintenance - Maintenance engineering - Requirements

Maintenance - Ingénierie de maintenance - Exigences Instandhaltung - Instandhaltungsengineering -

Anforderungen

This European Standard was approved by CEN on 16 October 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17666:2022 E

worldwide for CEN national Members.

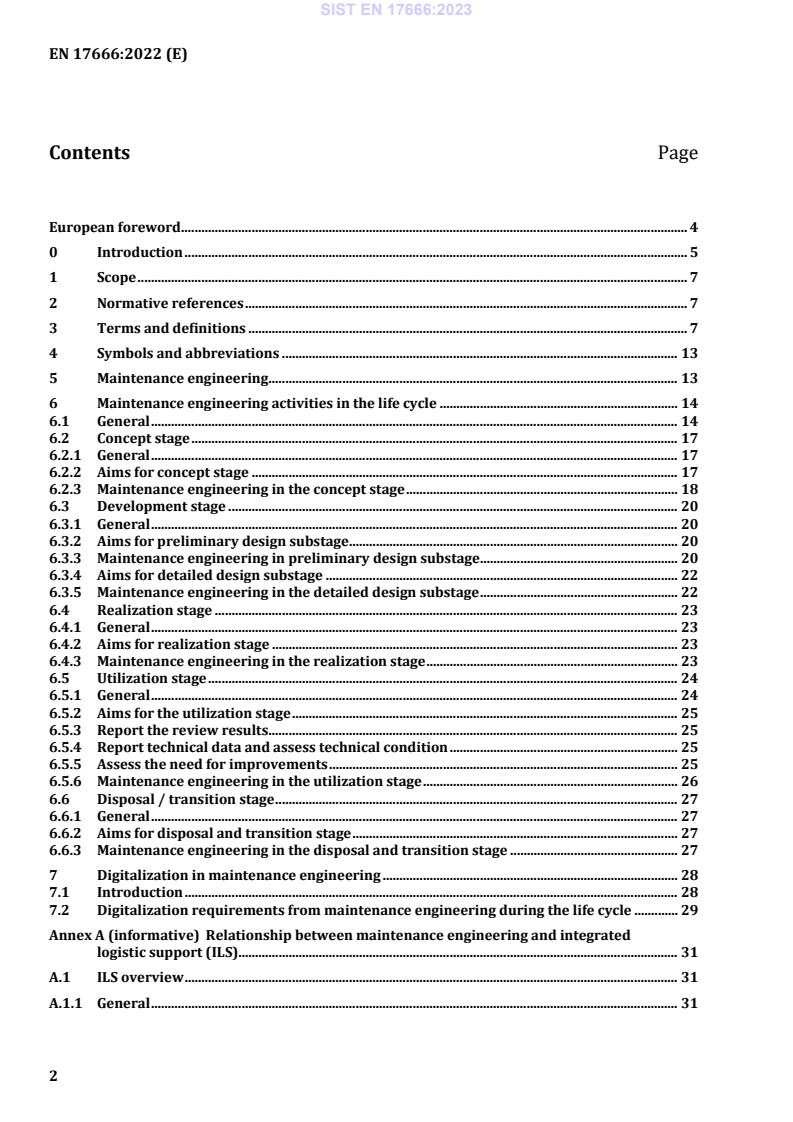

Contents Page

European foreword . 4

0 Introduction . 5

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Symbols and abbreviations . 13

5 Maintenance engineering . 13

6 Maintenance engineering activities in the life cycle . 14

6.1 General . 14

6.2 Concept stage . 17

6.2.1 General . 17

6.2.2 Aims for concept stage . 17

6.2.3 Maintenance engineering in the concept stage . 18

6.3 Development stage . 20

6.3.1 General . 20

6.3.2 Aims for preliminary design substage . 20

6.3.3 Maintenance engineering in preliminary design substage . 20

6.3.4 Aims for detailed design substage . 22

6.3.5 Maintenance engineering in the detailed design substage . 22

6.4 Realization stage . 23

6.4.1 General . 23

6.4.2 Aims for realization stage . 23

6.4.3 Maintenance engineering in the realization stage . 23

6.5 Utilization stage . 24

6.5.1 General . 24

6.5.2 Aims for the utilization stage . 25

6.5.3 Report the review results . 25

6.5.4 Report technical data and assess technical condition . 25

6.5.5 Assess the need for improvements . 25

6.5.6 Maintenance engineering in the utilization stage . 26

6.6 Disposal / transition stage . 27

6.6.1 General . 27

6.6.2 Aims for disposal and transition stage . 27

6.6.3 Maintenance engineering in the disposal and transition stage . 27

7 Digitalization in maintenance engineering . 28

7.1 Introduction . 28

7.2 Digitalization requirements from maintenance engineering during the life cycle . 29

Annex A (informative) Relationship between maintenance engineering and integrated

logistic support (ILS) . 31

A.1 ILS overview . 31

A.1.1 General . 31

A.1.2 ILS objectives . 31

A.1.3 Elements of ILS. 31

A.1.4 Logistic support analysis (LSA) . 32

A.2 Relationship between maintenance engineering and ILS. 32

Annex B (informative) Techniques, analyses and practices applicable to maintenance

engineering . 33

B.1 General . 33

B.2 Techniques, analyses and practices applicable to maintenance engineering . 33

Annex C (informative) Maintainability design within maintenance engineering . 39

C.1 General . 39

C.2 Design for maintainability. 39

Annex D (informative) Life cycle stages . 42

Bibliography . 43

European foreword

This document (EN 17666:2022) has been prepared by Technical Committee CEN/TC 319

“Maintenance”, the secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2022, and conflicting national standards shall be

withdrawn at the latest by May 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

0 Introduction

0.1 Scope and benefits of maintenance engineering

Maintenance engineering is a discipline applying competencies, methods, techniques and tools to develop

and support maintenance in order to ensure that an item is able to perform its required functions in a

safe, sustainable and cost-effective manner throughout the life cycle.

The prime aim of maintenance engineering is to contribute to the achievement of overall stakeholder

requirements through optimized and cost-effective maintenance as part of physical asset management.

The benefits of the contributions from maintenance engineering include, but are not limited to:

— achievement of dependability goals by influencing design;

— risk analysis related to maintenance;

— application of sustainability principles;

— achieved required integrity and safety level;

— achieved required performance and technical condition;

— improved life extension decisions;

— improved maintenance support performance;

— reduced environmental footprint by saving energy and raw materials consumption;

— improved competitiveness and output value.

0.2 Use of this document

This document is generic and provides guidance on the methodology to achieve maintenance engineering

aims.

The intended users of this document are personnel involved in design, procurement, construction,

commissioning, operation, improvement, maintenance and disposal/transition or decommissioning of

physical assets. No specific structure or size of organization is assumed so that maintenance engineering

effort should be tailored to suit specific applications and organisational requirements.

This document is based on the maintenance terminology as defined in EN 13306 Maintenance —

Maintenance terminology. Adjustments and additional terminology used, are found in Clause 3.

Clause 5 of this document describes maintenance engineering discipline and its objectives.

Clause 6 of this document describes maintenance engineering activities during the life cycle stages.

Activities are used to express the application of knowledge, skills and tools in maintenance engineering.

The following life cycle stages and substages are used, see 6.1:

1) concept stage with the following substages: feasibility and concept baseline;

2) development stage with the following substages: preliminary design and detailed design;

3) realization stage with the following substages: build and implementation / commissioning;

4) utilization stage with the following substage: operation and maintenance;

5) disposal/transition stage with the following substage: reuse, recycling or disposal.

NOTE These life cycle stages are harmonized as far as possible and based on what are used in EN 16646 [7]

and IEC 60300 series [see Bibliography]. Disposal and transition are used instead of retirement used in IEC 60300

series. See an overview in Annex D.

While maintenance engineering has the most impact when applied during the concept stage and design

of a physical item, this document is applicable to maintenance engineering in all life cycle stages, and for

different scenarios, for example:

— manufacturer producing one equipment and then maintaining it;

— transfer of property at commissioning to a buyer who will be in charge of maintenance;

— transfer of property at commissioning followed by a warranty period. The seller is responsible during

the warranty and the buyer thereafter;

— maintenance service (sub) contract by the seller to the buyer or to a third party.

Clause 7 of this document describes maintenance engineering and digitalization.

The document also includes informative Annexes A to D with additional guidance.

Processes are defined as set of interrelated or interacting activities that use inputs to deliver an intended

result (3.24). In the context of this document, the term “maintenance engineering activities” is used to

express the application of knowledge, skills and tools to support the processes given in EN 17007 [10].

While EN 17007 describes the processes, this document FprEN 17666 follows the life cycle stages.

0.3 Related standards

This document is part of a group of European maintenance standards published by CEN/TC 319

Maintenance giving requirements and guidance on maintenance, see the committee site on

https://standards.cencenelec.eu/dyn/www/f?p=CEN:105::RESET and Bibliography [2] to [7] and [9] to

[12].

In addition, there are a number of standards published in CEN, ISO and IEC which address maintenance

as part of asset management and dependability view.

The asset management standards in the ISO 55000 series [59 to 61] address the overall requirements for

assets, decision criteria, strategic asset management plan (SAMP) and asset management plan. EN 17485

[12] and EN 16646 [7] create a bridge between these ISO standards and the EN maintenance standards

which determine the requirements for maintenance engineering.

The IEC dependability standards (principally the IEC 60300 series) address the management and

technical activities to produce and / or sustain a dependable item, which is one where there is justified

confidence that it will operate as desired and satisfy agreed stakeholder needs and expectations.

1 Scope

This document specifies the maintenance engineering discipline throughout the entire life cycle.

This document gives guidance on how maintenance engineering can contribute to the assurance of

required dependability to achieve a sustainable balance between performance, risk and costs.

This document refers to standards that further describe detailed methods and techniques.

This document does not give guidance on how to set up systems and infrastructure for maintenance

engineering nor does it include guidance on software maintenance.

NOTE 1 For software components of an item, the maintenance activities are covered in ISO/IEC/IEEE 14764

[54].

NOTE 2 The overall maintenance process is covered by EN 17007 [10].

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 13306, Maintenance — Maintenance terminology

3 Terms and definitions

For the purposes of this document the terms and definitions given in EN 13306 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/

3.1

maintenance

combination of all technical, administrative and managerial actions during the life cycle (3.10) of an item

(3.13) intended to retain it in, or restore it to, a state in which it can perform the required function (3.8)

Note 1 to entry: Technical maintenance actions include observation and analyses of the item state (e.g.

inspection, monitoring, testing, diagnosis, prognosis, etc.) and active maintenance actions (e.g. repair,

refurbishment).

Note 2 to entry: See also the definitions of improvement and modification in EN 13306.

[SOURCE: EN 13306:2017, 2.1]

3.2

maintenance engineering

engineering discipline applying competencies (3.14), methods, techniques and tools to develop and

support maintenance (3.1) in order to assure that an item (3.13) is able to perform its required functions

(3.8) in a safe, sustainable and cost-effective (3.9) manner throughout the life cycle (3.10)

3.3

maintenance management

all activities of the management that determine the maintenance (3.1) requirements, objectives,

strategies and responsibilities, and implementation of them by such means as maintenance planning,

maintenance control, and the improvement of maintenance activities and economics

[SOURCE: EN 13306:2017, 2.2]

3.4

maintenance plan

structured and documented set of tasks that include the activities, procedures, resources and the time

scale required to carry out maintenance (3.1)

[SOURCE: EN 13306:2017, 2.5]

3.5

maintenance strategy

management method used in order to achieve the maintenance objectives

EXAMPLE Outsourcing of maintenance, allocation of resources, etc.

[SOURCE: EN 13306:2017, 2.4]

3.6

failure management policy

maintenance activities, operational changes, design modifications or other actions in order to mitigate

the consequences of failure

[SOURCE: EN 60300-3-11:2009, 3.1.6]

3.7

operation

combination of all technical, administrative and managerial actions, other than maintenance actions, that

results in the item being in use

Note 1 to entry: Maintenance actions carried out by operators are not included in operation.

Note 2 to entry: In this document, operational and operations are used as synonyms.

[SOURCE: EN 13306:2017, 2.9, modified – Note 2 to entry have been added.]

3.8

required function

function, combination of functions, or a total combination of functions of an item which are considered

necessary to fulfil a given requirement

Note 1 to entry: “Necessary to fulfil a given requirement” may also include asset value preservation.

Note 2 to entry: The given requirement may be expressed or implied and may in some cases be below the original

design specifications.

Note 3 to entry: The required function, by implication, also covers what the item shall not do.

[SOURCE: EN 13306:2017, 2.6]

3.9

cost-effective

balance of cost, risk (3.26), opportunity and performance taking into account stakeholder objectives

Note 1 to entry: Performance covers quality, short and long term.

3.10

life cycle

series of stages through which an item goes, from its conception to disposal

Note 1 to entry: The stages identified will vary with the application. Reuse and recycle follows disposal.

[SOURCE: EN 13306:2017, 4.18, modified — List of examples of life cycle stages is omitted because

EN 17666 defines the stages given in Clause 6.]

3.11

life cycle cost

sum of the costs generated during the life cycle (3.10) of the item (3.13)

[SOURCE: EN 13306:2017, 11.1, modified — Note 1 to entry is omitted because EN 17666 defines the

stages given in Clause 6.]

3.12

physical asset

item (3.13) that has potential or actual value to an organization

Note 1 to entry: Examples of physical assets are components, machines, plants, buildings, infrastructures, etc.

[SOURCE: EN 13306:2017, 3.2]

3.13

item

part, component, device, subsystem, functional unit, equipment or system that can be individually

described and considered

[SOURCE: EN 13306:2017, modified — Notes 1, 2 and 3 to entry are omitted]

3.14

competence

proven ability to use knowledge, skills (3.15), and personal, social and/or methodological abilities, in

work or study situations and in professional and personal development

Note 1 to entry: Competence is described in the terms of responsibility and autonomy.

[SOURCE: EN 15628:2014, 3.1]

3.15

skills

ability to apply knowledge and use know-how to complete tasks and resolve problems

Note 1 to entry: Skills are described as cognitive (involving the use of logical, intuitive and creative thinking) or

practical (involving manual dexterity and the use of methods, tools and instruments).

[SOURCE: EN 15628:2014, 3.6]

3.16

dependability

ability to perform as and when required

Note 1 to entry: Dependability includes availability (3.20), safety, security, durability, economics and their

influencing factors (reliability, maintainability (3.19), supportability (3.17), conditions of use and operators

influence).

Note 2 to entry: Dependability is used as a collective term for the time-related quality characteristics of an item.

[SOURCE: EN 13306:2017, 2.7, modified — In Note 1 to entry “maintenance support performance” is

replaced by “supportability”]

3.17

supportability

ability to be supported to sustain the required availability with a defined operational profile and given

logistic and maintenance resources

Note 1 to entry: Supportability of an item results from the inherent maintainability, combined with factors

external to the item that affect the relative ease of providing the required maintenance and logistic support.

[SOURCE: IEC 60050-192:2015, 192-01-31]

3.18

integrated logistic support

ILS

management process to determine and coordinate the provision of all materials and resources required

to meet the needs for operation and maintenance

Note 1 to entry: ILS is a process to determine the optimal maintenance support. ILS integrates logistic support

analysis and the development of resources, see Annex A.

[SOURCE: IEC 60050-192:2015, 192-01-30, modified — Note 1 to entry added]

3.19

maintainability

ability of an item under given conditions of use, to be retained in, or restored to, a state in which it can

perform a required function (3.8), when maintenance (3.1) is performed under given conditions and using

stated procedures and resources

Note 1 to entry: Maintainability may be quantified using appropriate measures or indicators and is then referred

to as maintainability performance.

[SOURCE: EN 13306:2017, 4.5]

3.20

availability

ability of an item to be in a state to perform as and when required, under given conditions, assuming that

the necessary external resources are provided

Note 1 to entry: Required external resources, other than maintenance resources, do not affect the availability of

the item although the item may not be available from the user’s viewpoint.

Note 2 to entry: This ability depends on the combined aspects of the reliability, maintainability of the item, the

maintenance supportability and the maintenance actions carried out on the item.

Note 3 to entry: Availability may be quantified using appropriate measures or indicators and is then referred to

as availability performance (see EN 13306:2017, 4.9).

Note 4 to entry: There are several types of availability, for example: achieved availability (3.21), operational

availability (3.22) and inherent availability (3.23).

[SOURCE: EN 13306:2017, 4.7, modified — Note 4 to entry added]

3.21

achieved availability

probability than an item when used under stated conditions in an ideal support environment will operate

satisfactorily at any point in time

3.22

operational availability

availability (3.20) experienced under actual conditions of operation and maintenance

Note 1 to entry: Operational availability is determined considering down time due to failures and associated

delays, but excluding external causes.

[SOURCE: IEC 60050-192:2015, 192-08-03]

3.23

inherent availability

availability (3.20) provided by the design under ideal conditions of operation and maintenance

Note 1 to entry: Delays associated with maintenance, such as logistic and administrative delays, are excluded.

[SOURCE: IEC 60050-192:2015, 192-08-02]

3.24

process

set of interrelated or interacting activities that use inputs to deliver an intended result

Note 1 to entry: Whether the “intended result” of a process is called output, product or service depends on the

context of the reference.

Note 2 to entry: Inputs to a process are generally the outputs of other processes and outputs of a process are

generally the inputs to other processes.

Note 3 to entry: Two or more interrelated and interacting processes in series can also be referred to as a process.

Note 4 to entry: Processes in an organization are generally planned and carried out under controlled conditions to

add value.

Note 5 to entry: A process where the conformity of the resulting output cannot be readily or economically validated

is frequently referred to as a “special process”.

[SOURCE: EN ISO 9000:2015, 3.4.1 and EN 17007:2017, 3.12, modified — Note 6 to entry in the original

definition from EN ISO 9000:2015 has been deleted.]

3.25

stakeholder

person or organization that can affect, be affected by, or perceive themselves to be affected by a decision

or activity

[SOURCE: ISO 55000:2014, 3.1.22, modified — Note 1 to entry deleted.]

3.26

risk

effect of uncertainty on objectives

Note 1 to entry: An effect is a deviation from the expected. It can be positive, negative or both, and can address,

create or result in opportunities and threats.

Note 2 to entry: Objectives can have different aspects and categories and can be applied at different levels.

Note 3 to entry: Risk is usually expressed in terms of risk sources, potential events, their consequences and their

likelihood.

[SOURCE: ISO 31073:2022, 3.1.1]

3.27

sustainability

state of the global system, including environmental, social and economic aspects, in which the needs of

the present are met without compromising the ability of future generations to meet their own needs

Note 1 to entry: The environmental, social and economic aspects interact, are interdependent and are often referred

to as the three dimensions of sustainability.

Note 2 to entry: Sustainability is the goal of sustainable development.

Note 3 to entry: Sustainability aspects of maintenance covers but are not limited to unnecessary maintenance, rest

useful lifetime, maintenance efficiency, (re)use of materials.

[SOURCE: ISO Guide 82:2019, 3.1, modified — Note 3 to entry has been added.]

4 Symbols and abbreviations

For the purposes of this document, the following symbols and abbreviations apply.

CBM Condition based maintenance

FMEA Failure modes and effects analysis

FME(C)A Failure modes, effects (and criticality) analysis

HAZOP Hazards and operability analysis

HSE Health, safety, and environment

ILS Integrated logistic support

IEC International Electrotechnical Commission (https://www.iec.ch/)

KPI Key performance indicator

LCA Life cycle assessment

LCC Life cycle cost

LCP Life cycle profit

OH&S Occupational health and safety

RAM Reliability, availability and maintainability

RAMS Reliability, availability, maintainability and safety

RBD Reliability block diagram

RBI Risk based inspection

RCA Root cause analysis

RCM Reliability centred maintenance

5 Maintenance engineering

Maintenance engineering is an engineering discipline applying competencies, methods, techniques and

tools to develop and support maintenance in order to ensure that an item is able to perform its required

functions in a safe, sustainable and cost-effective manner throughout the life cycle.

The maintenance engineering competencies shall be maintained through continuing professional

development.

Maintenance engineering makes use of basic knowledge and sciences (mathematics, physics, chemistry

and biology), as well as of other areas of engineering knowledge (Civil, Mechanics, Materials,

Mechatronics, Electrotechnics, Informatics, Data Analysis etc.) together with their methods and

supporting tools. Examples of relevant techniques, analyses and practices that may be used in

maintenance engineering are given in Annex B.

Maintenance engineering embodies the competences to enable the creation, development and

application of technology and procedures for maintenance of equipment throughout its entire life cycle.

This is achieved through a structured approach of identifying opportunities, developing and analysing

solutions, making trade-offs and considering risks using clearly defined steps; these include but are not

limited to:

a) analysis of needs, objectives and timescale;

b) identification of constraints and stakeholder requirements such as: safety, sustainability, statutory

requirements, ethical and socio-economic impacts;

c) evaluation of risk;

d) development of actions, procedures and proposals including modelling with an appropriate level of

detail. Iterations of the preceding steps may be necessary, to achieve objectives;

e) finalization of actions, procedures and proposals, considering identified restrictions and implement

the decisions agreed upon.

The relationship between the maintenance engineering competences and maintenance engineering

activities is described in Clause 6.

6 Maintenance engineering activities in the life cycle

6.1 General

Maintenance engineering activities are focused on assuring that an item fulfils its required functions in a

safe, sustainable and cost-effective manner. The type of activity required changes through the lifespan of

an item: initially directed at developing and documenting maintenance requirements, changing into

delivering and optimizing item maintenance. Throughout the life cycle, maintenance engineering activity

inputs to design and results shall be traceable and auditable, see more guidance on information, data

management and documentation in ISO 55002 [61] and EN 13460 [3]. The results from maintenance

activities should follow a defined asset hierarchy approved by the relevant stakeholders.

NOTE 1 See examples of asset hierarchy in EN 17485 [12] and EN ISO 14224 [36].

This document uses the following life cycle stages:

1. concept;

2. development;

3. realization;

4. utilization;

5. disposal/transition.

NOTE 2 The life cycle stages are a harmonization of those in other existing maintenance related standards (see

Annex D). Individual organizations might use different terminology.

Individual stages rarely, if ever, have precise boundaries as activities from one stage tend to gradually

diminish as the following stage commences.

The contribution of maintenance engineering to item design and utilization depends on the detail of the

proposal, level within the asset hierarchy and the life cycle stage. Maintenance engineering should

interact with all relevant disciplines in order to fulfil the stakeholder objectives. The extent of activities

will also depend upon the benefit which can be derived and the degree of control the organization can

exert.

Design and maintenance engineering inputs are influenced by internal and external factors to an

organization such as: legislation, socio-economic conditions, technologies, technical condition of

interrelated physical assets, logistics, competencies and the characteristics of the organization. The need

to balance these factors in order to satisfy stakeholders may result in suboptimal maintainability and

supportability.

Table 1 gives an overview of the maintenance engineering aims, inputs and activities during the life cycle

which realize asset value for the stakeholders through dependability. The following 6.2 to 6.6 address the

range of activities which could be undertaken during the life cycle of an item; those planning and

undertaking the work shall identify the most cost-effective approaches to achieve the desired outcomes.

Tables 2 to 7 provide a more detailed view of the primary activities in each life cycle stage, their inputs,

results and interactions. “Input” in Table 2 to 7 refers to typical inputs for maintenance engineering.

Generally, the results (“output”) from one stage are part of the input to the next stage. Stakeholders in

maintenance engineering output are listed as well as principal constraints. These tables present the most

common aspects of maintenance engineering and thus should not be regarded as exhaustive: the need

for additional or fewer activities or interactions should be evaluated as part of the implementation.

During the different stages and substages communication between the project owners, the operational

organization and the engineering organization is essential for establishment of requirements to meet

stakeholder needs. The maintenance policy is the basis for maintenance engineering in the life cycle and

shall be consistent with the overall organization policy and objectives.

Annex B lists examples of relevant techniques and tools for maintenance engineering in the life cycle

stages.

Table 1 — Maintenance engineering aims, inputs and activities during the life cycle

Life cycle Life cycle substage Aims of maintenance Maintenance engineering

stage engineering activities activities and inputs to the

different life cycle stages

Concept Feasibility Provide early technical input Assist in definition of design

to the feasibility study solutions by providing

concerning maintenance assessment of maintenance

requirements resulting from consequences associated with

proposed solutions them and their impact on

stakeholder requirements.

Concept baseline Contribute to the definition Deliver assessment of

of baseline design though maintenance requirements

assessment of maintenance and maintainability of

alternative options. Contribute

requirements

to achievement of stakeholder

requirements such as

assessment of the

dependability, sustainability

and safety of alternative

options.

Ensure options comply with

all applicable statutory and

organisational requirements.

Life cycle Life cycle substage Aims of maintenance Maintenance engineering

stage engineering activities activities and inputs to the

different life cycle stages

Development Preliminary design Influence design to achieve Contribute to the

required dependability dependability assessment of

performance. the selected whole asset

solution design options

through assessment of

maintenance and

maintainability.

Detailed design Develop maintenance tasks Support design activities to

and assist in design efforts to achieve reliability,

achieve required maintainability and

maintainability levels and supportability goals. Develop

provide assurance of preliminary maintenance

operational availability. processes, instructions and

identify maintenance related

technological opportunities.

Define maintenance plans,

develop task descriptions.

Realization Build Implement the maintenance Advise on and participate in

decisions from the concept inspection, testing and

and development stages conformity assessment during

the build process. Update

maintenance plans as required

in response to as-built

systems.

Implementation and Implement the maintenance Identify resource and

decisions from the concept, competence requirements for

commissioning

development stages and maintenance and implement

during the commissioning, accordingly.

preparing handover

Implement maintenance plans

including inspection plans,

operator maintenance (where

applicable) and condition

monitoring plans.

Validate maintenance

procedures as required.

Contribute to e.g. start-up, test

run and performance

acceptance test.

Life cycle Life cycle substage Aims of maintenance Maintenance engineering

stage engineering activities activities and inputs to the

different life cycle stages

Utilization Operation and Execute maintenance tasks Undertake task analysis,

maintenance and update plans in order to specify schedules and plans,

achieve the dependability repair plans and condition

objectives based maintenance

development plans.

Update maintenance plans and

other selected failure

management policies through

technical assessment of

maintenance outcomes and in

response to changing

operating conditions.

Participate in revision of

maintenance schedules and

planning of relevant activities

to improve operations. Assist

in developing operating

practices and operator skills

(where appropriate).

Participate in analyses of

support requirements.

Disposal/ Reuse, recycling or Facilitate reuse, recycling or Estimate end of useful life of

items or assets. Assist in

transition disposal disposal of an item or asset

identification of items for

reuse, recycling, re-

manufacturing, obsolescence

or disposal.

6.2 Concept stage

6.2.1 General

The concept stage includes feasibility studies and concept baseline development.

The requirements for assets to be acquired are defined on the basis of the critical success factors (see

EN 17485 [12] and EN 16646 [7]) which are identified within the feasibility stage. If required, feasibility

studies are performed to assess the practicality of a proposed project or item.

The main activity in the concept baseline development is the determination of the physical asset solution

and maintenance requirements of the whole project or item based on feasibility studies (if required) and

critical success factors. This may require assessment of alternative asset solutions from the dependability

point of view in order to identify the preferred solution. Maintenance engineering input in this stage

provides more detailed assessment of inputs made during the feasibility substage.

6.2.2 Aims for concept stage

As part of the development and evaluation of design solutions leading to a concept baseline design the

aim is to provide early technical assessment and input regarding the maintainability and maintenance

impact of proposed solutions and how these relate to stakeholder requirements.

Technical assessment of selected or alternative asset design solutions include, but are not limited to:

— the relevance and effect of maintenance and maintainability;

— the maintenance needs;

— maintenance load (such as competences and resources);

— opportunities to extend operational life;

— the ability to meet specified requirements, including safety and security;

— Integrated logistic support (ILS) requirements where relevant (see Annex A).

The early stages of design development provide the most cost-effective opportunities to influence

reliability, availability, maintainability and safety (RAMS) as once a design is fixed, any changes to

improve these attributes will be significantly more expensive and time-consuming to achieve. Increased

reliability and maintainability may increase investment costs but reduce the costs of ownership.

Maintenance engineering activities should therefore determine maintenance value and costs involved in

order to support trade-off analysis where required.

6.2.3 Maintenance engineering in the concept stage

Table 2 describes maintenance engineering primary activities and their input, output, stakeholders,

interfaces and constraints for the concept stage.

Table 2 — Maintenance engineering in the concept stage

Primary activities

1. contribute to achievement of stakeholder requirements such as assessment of the dependability,

sustainability and safety of alternative options;

2. contribute to the definition of design solutions by providing assessment of maintenance

consequences associated with them and their impact on stakeholder requirements;

3. deliver assessment of maintenance requirements and maintainability of alternative options;

4. deliver information for analysis with generic reliability and maintainability data that show the

effects of the proposed solutions related to specific topics such as HSE, maintenance needs,

availability, personnel, energy consumption, life cycle cost, etc.;

5. deliver documentation of assumptions used in analyses for use in next stage of project, including

implicit constraints, uncertainties and expectations.

Input Output

— maintenance policy (fundamentals, company — maintainability results;

principles);

— maintainability requirements;

— design capacity;

— evaluation of maintenance concepts options

— dependability requirements; for struc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...