ASTM D5287-08(2015)

(Practice)Standard Practice for Automatic Sampling of Gaseous Fuels (Withdrawn 2024)

Standard Practice for Automatic Sampling of Gaseous Fuels (Withdrawn 2024)

SIGNIFICANCE AND USE

4.1 This practice should be used when and where a representative sample is required. A representative sample is necessary for accurate billing in custody transfer transactions, accurate compositional analysis of the flowing stream, gravity determination for flow calculations and other desired information concerning the properties of the stream contents.

4.2 This practice is not intended to preempt existing contract agreements or regulatory requirements.

4.3 Principles pertinent to this practice may be applied in most contractual agreements.

4.4 Warning—Many gages are extremely flammable and can contain toxic substances. Caution should be taken in all aspects of sample collection and handling. Sample vessels should only be handled in well ventilated locations away from sparks and flames. Improper handling can result in an explosion or injury, or both.

SCOPE

1.1 This practice covers the collection of gaseous fuels and their synthetic equivalents using an automatic sampler.

1.2 This practice applies only to single-phase gas mixtures. This practice does not address a two-phase stream.

1.3 This practice includes the selection, installation, and maintenance of automatic sampling systems.

1.4 This practice does not include the actual analysis of the acquired sample. Other applicable ASTM standards, such as Test Method D1945, should be used to acquire that information.

1.5 The selection of the sampling system is dependent on several interrelated factors. These factors include source dynamics, operating conditions, cleanliness of the source gases, potential presence of moisture and hydrocarbon liquids, and trace hazardous components. For clean, dry gas sources, steady source dynamics, and normal operating conditions, the system can be very simple. As the source dynamics become more complex and the potential for liquids increases, or trace hazardous components become present, the complexity of the system selected and its controlling logic must be increased. Similarly, installation, operation, and maintenance procedures must take these dynamics into account.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This practice covered the collection of gaseous fuels and their synthetic equivalents using an automatic sampler.

Formerly under the jurisdiction of Committee D03 on Gaseous Fuels, this practice was withdrawn in February 2024. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5287 − 08 (Reapproved 2015)

Standard Practice for

Automatic Sampling of Gaseous Fuels

This standard is issued under the fixed designation D5287; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice covers the collection of gaseous fuels and

D1945 Test Method for Analysis of Natural Gas by Gas

their synthetic equivalents using an automatic sampler.

Chromatography

1.2 This practice applies only to single-phase gas mixtures.

D5504 TestMethodforDeterminationofSulfurCompounds

This practice does not address a two-phase stream.

in Natural Gas and Gaseous Fuels by Gas Chromatogra-

phy and Chemiluminescence

1.3 This practice includes the selection, installation, and

2.2 Other Standards:

maintenance of automatic sampling systems.

AGA Report Number 7 Measurement of Gas by Turbine

Meters

1.4 This practice does not include the actual analysis of the

API 14.1 Collecting and Handling of Natural Gas Samples

acquired sample. Other applicable ASTM standards, such as

for Custody Transfer

Test Method D1945, should be used to acquire that informa-

API 14.3 Part 2 (AGA Report Number 3)

tion.

GPA Standard 2166 Methods of Obtaining Natural Gas

1.5 The selection of the sampling system is dependent on

Samples for Analysis by Gas Chromatography

several interrelated factors. These factors include source

ISO-10715 Natural Gas—Sampling Guidelines

dynamics, operating conditions, cleanliness of the source

NACE Standard MR-01-75 Standard Material Require-

gases, potential presence of moisture and hydrocarbon liquids, ments. Sulfide Stress Cracking Resistant-Metallic Materi-

and trace hazardous components. For clean, dry gas sources, als for Oilfield Equipment

2.3 Federal Documents:

steady source dynamics, and normal operating conditions, the

CFR 49 Code of Federal Regulations, Title 49,173, 34(e), p.

system can be very simple. As the source dynamics become

more complex and the potential for liquids increases, or trace

hazardous components become present, the complexity of the

3. Terminology

system selected and its controlling logic must be increased.

3.1 Definitions of Terms Specific to This Standard:

Similarly, installation, operation, and maintenance procedures

3.1.1 automatic sampler—(seeFig.1(a)and(b))amechani-

must take these dynamics into account.

cal system, composed of a sample probe, sample loop, sample

1.6 The values stated in inch-pound units are to be regarded

extractor, sample vessel, and the necessary logic circuits to

as standard. The values given in parentheses are mathematical

control the system throughout a period of time, the purpose of

conversions to SI units that are provided for information only

and are not considered standard.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1.7 This standard does not purport to address all of the

Standards volume information, refer to the standard’s Document Summary page on

safety concerns, if any, associated with its use. It is the

the ASTM website.

responsibility of the user of this standard to establish appro- Available from American Gas Association, 400 N. Capitol St. N.W.,

Washington, DC 20001, http://www.aga.org/.

priate safety and health practices and determine the applica-

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

bility of regulatory limitations prior to use.

4th Floor, New York, NY 10036, http://www.ansi.org.

Available from Gas ProcessorsAssociation (GPA), 6526 E. 60th St.,Tulsa, OK

74145, http://www.gasprocessors.com.

Available from International Organization for Standardization (ISO), 1, ch. de

This practice is under the jurisdiction of ASTM Committee D03 on Gaseous la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

Fuels and is the direct responsibility of Subcommittee D03.01 on Collection and www.iso.ch.

Measurement of Gaseous Samples. Available from NACE International (NACE), 1440 South Creek Dr., Houston,

CurrenteditionapprovedJune1,2015.PublishedJuly2015.Originallyapproved TX 77084-4906, http://www.nace.org.

in 1992. Last previous edition approved in 2008 as D5287 – 08. DOI: 10.1520/ Available from Superintendent of Documents, Government Printing Office,

D5287-08R15. Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5287 − 08 (2015)

FIG. 1 Continuous Composite Samplers

which is to compile representative samples in such a way that 3.1.7 sample vessel—the container in which the sample is

the final collection is representative of the total composition of collected, stored, and transported to the analytical equipment.

the gas stream for that period of time. This is also referred to as a sample cylinder.

3.1.2 representative sample—a volume of gas that has been 3.1.8 source dynamics—changes in gas supplies, operating

obtained in such a way that the composition of this volume is pressures, temperatures, flow rate, hydrocarbon dew point, and

the same as the total composition of the gas stream from which other factors that may affect composition or state, or both.

it was taken.

4. Significance and Use

3.1.3 retrograde condensation—the formation of liquid

4.1 This practice should be used when and where a repre-

phase by pressure drop or temperature increase on a gas stream

sentative sample is required.Arepresentative sample is neces-

at or below hydrocarbon dew point.

sary for accurate billing in custody transfer transactions,

3.1.4 sample extractor—a device to remove the sample

accurate compositional analysis of the flowing stream, gravity

from the flowing stream or sample loop and put it into the

determination for flow calculations and other desired informa-

sample vessel.

tion concerning the properties of the stream contents.

3.1.5 sample loop—the valve, tubing, or manifold(s), or

4.2 This practice is not intended to preempt existing con-

combination thereof, used for conducting the gas stream from

tract agreements or regulatory requirements.

the probe to the sampling device and back to the source pipe

4.3 Principles pertinent to this practice may be applied in

(or atmosphere).

most contractual agreements.

3.1.6 sample probe—that portion of the sample loop at-

tached to and extending into the pipe containing the gas to be 4.4 Warning—Many gages are extremely flammable and

can contain toxic substances. Caution should be taken in all

sampled.

aspects of sample collection and handling. Sample vessels

should only be handled in well ventilated locations away from

sparks and flames. Improper handling can result in an explo-

Bergman, D. F., Tek, M. R., and Katz, D. L., Retrograde Condensation in

Natural Gas Pipelines, American Gas Association, Arlington, VA, 1975. sion or injury, or both.

D5287 − 08 (2015)

5. Material Selection

5.1 The sampling system (including probes, tubing, valving

and other components) should be constructed of suitable inert,

or passivated, materials that are compatible with all aspects of

the product and the sampling practice, both internal and

external conditions to ensure that constituents in the fuel

stream do not degrade these components or alter the compo-

sition of the sampled gas.

5.2 The selected material should be inert to and not absorp-

tive of all expected components in the gas stream.

5.3 When sour gas (gases that contain hydrogen sulfide or

carbon dioxide, or both) are present or suspected, consult the

recommendations in NACE Standard MR-01-75.

5.4 Contaminates, other than those listed above, should be

identified and addressed by the appropriate industry

recommendations, guidelines and standards.

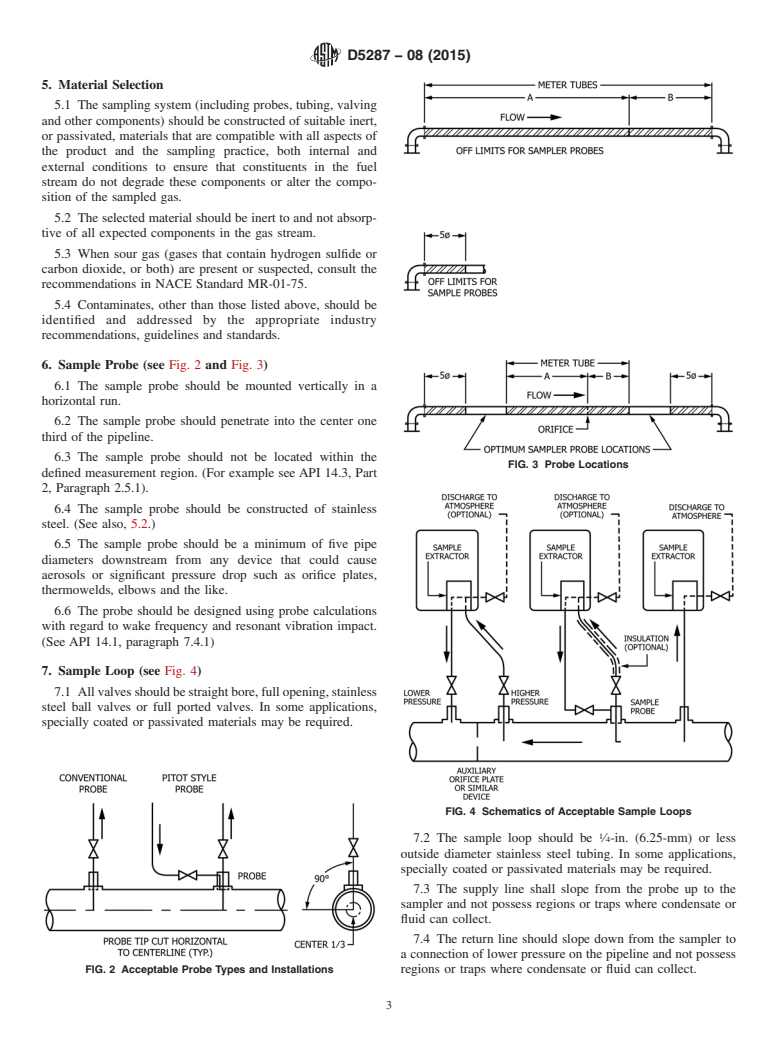

6. Sample Probe (see Fig. 2 and Fig. 3)

6.1 The sample probe should be mounted vertically in a

horizontal run.

6.2 The sample probe should penetrate into the center one

third of the pipeline.

6.3 The sample probe should not be located within the

FIG. 3 Probe Locations

defined measurement region. (For example see API 14.3, Part

2, Paragraph 2.5.1).

6.4 The sample probe should be constructed of stainless

steel. (See also, 5.2.)

6.5 The sample probe should be a minimum of five pipe

diameters downstream from any device that could cause

aerosols or significant pressure drop such as orifice plates,

thermowelds, elbows and the like.

6.6 The probe should be designed using probe calculations

with regard to wake frequency and resonant vibration impact.

(See API 14.1, paragraph 7.4.1)

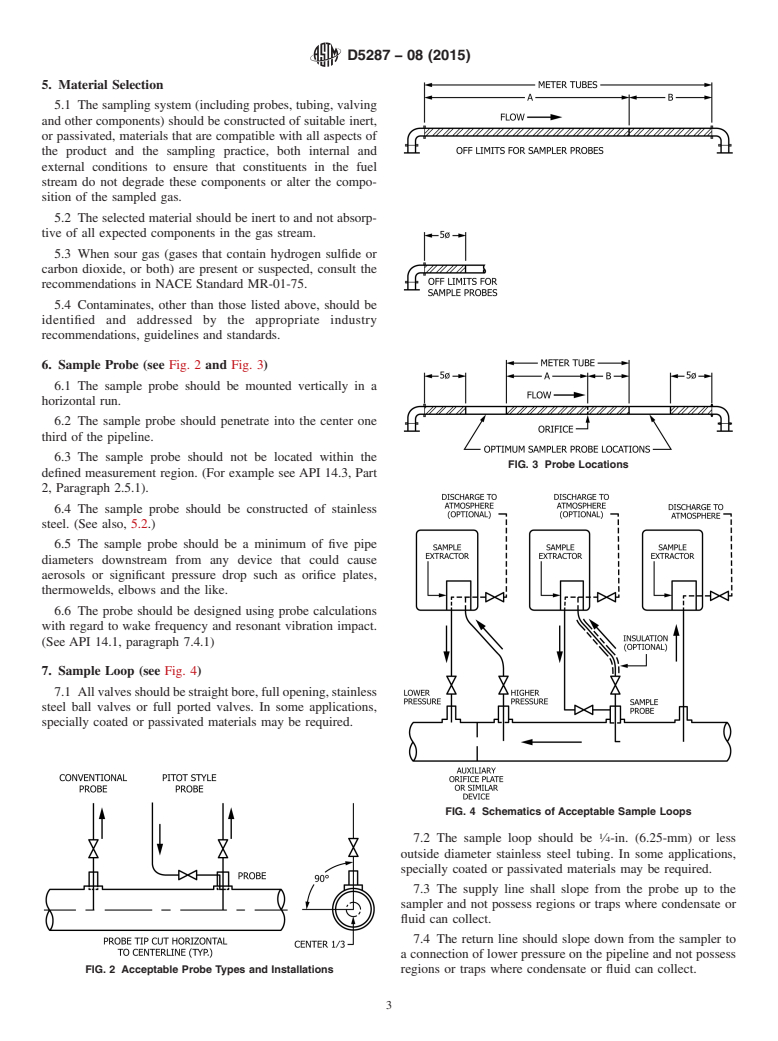

7. Sample Loop (see Fig. 4)

7.1 Allvalvesshouldbestraightbore,fullopening,stainless

steel ball valves or full ported valves. In some applications,

specially coated or passivated materials may be required.

FIG. 4 Schematics of Acceptable Sample Loops

7.2 The sample loop should be ⁄4-in. (6.25-mm) or less

outside diameter stainless steel tubing. In some applications,

specially coated or passivated materials may be required.

7.3 The supply line shall slope from the probe up to the

sampler and not possess regions or traps where condensate or

fluid can collect.

7.4 The return line should slope down from the sampler to

a connection of lower pressure on the pipeline and not possess

FIG. 2 Acceptable Probe Types and Installations regions or traps where condensate or fluid can collect.

D5287 − 08 (2015)

7.5 The supply line should be as short as possible, with a extractor adds incremental grabs (samples) to the sample

minimum number of bends. vessel. This only applies to the fixed volume vessels.

8.3.1.2 Electronic Tracing—Amagnetic type system can be

7.6 The sample loop should be insulated or heat traced, or

attached to the constant pressure piston style cylinders to track

both, if ambient temperature conditions could cause conden-

the movement of the internal piston during the filling process.

sation of the gas flowing through the loop.

A 4–20 ma signal system (or similar technology) can be

7.7 Filters or strainers that could cause the sample to be

monitored by computer systems or by preset signal verification

biased or altered are not allowed in the sample loop.

process.

8.3.1.3 Pressure Verification—While not verifying the fill-

7.8 Flow through the sample loop should be verified.

ing time frame, a simple test of the cylinder pressure can

8. Automatic Sampler (see Fig. 1(a) and (b))

validate that it was filled to pipeline line pressure.

8.3.2 Verification of Sample Extractor’s Output—Numerous

8.1 Installation—The sampler shall be mounted higher than

devices are available to check the output of the sample

the sample probe. It should be as close to the sample probe as

extractor. The device’s output may be a contact closure, a 4 to

conditions allow. Manufacturer’s specific instructions should

20 mA signal, a power pulse, or any other type that can be

be referenced.

recorded. This applies to all vessel types.

8.2 Maintenance—The sampler should be designed for easy

8.3.3 Pressure Transducer—Like a chart recorder, the pres-

field maintenance. A preventative maintenance schedule as

sure transducer measures the increasing pressure within a fixed

outlined by the manufacturer should be followed.

volume vessel.

8.3 Verification—The sampling personnel should be able to

8.3.4 Calculation Method—When a free-floating piston-

verify that the sample vessel was filled as planned. This can be

type vessel is properly installed with full pipeline pressure on

accomplished by several methods:

the pre-charge side, the only way product can move the piston

8.3.1 Cylinder Filling Verification—See Fig. 5.

is by way of the sample extractor. If the frequency and

8.3.1.1 Chart Recorder—The recorder should be commonly

displacement are known, the piston’s position is verification of

connected to a constant (fixed) volume sample vessel to

proper filling (estimated volume displacement) from the

indicate and record the increased in pressure as the sample

sample extractor and should be equal to the determined

displacement in the free-floating piston vessel. 100 sample

bites, grabs or aliquots of 0.5 cc volume should equal 50 cc in

the cylinder.) Compensation for changes in pipeline pressure

and ambient temperature changes must be considered when

present.

8.4 Control Methods—(see Fig. 1(a) and (b)) Two methods

of controlling samplers are currently recognized:

8.4.1 Proportional-to-FlowControl—Thismethodpacesthe

sampler with respect to flow.The controller shall be capable of

trackingthepipeline’sflowrateaccurately.Thismethodshould

be used when the variance of the flow rate is significant or

when flow ceases periodically or is intermittent.

8.4.2 Time-Based Control—This method paces the sample

with respect to time only. Take care to avoid sampling from a

stagnant source. The use of differential pressure switches and

othersimilardevicesmaybeusedtostopthesamplingprocess.

9. Sample Vessels

9.1 Types—There are currently two recognized types, both

of which are in the shape of a cylinder:

9.1.1 Variable Volume—Constant Pressure (see Fig. 1(a))—

These cylinders are commonly manufactured as free-floating

piston configurations. Pipeline pressure is maintained on the

“pre-charge” side of this piston.The sampler connects with the

“product” side of the piston. The sampler pumps the gas into

the product side of the vessel and moves the piston, thus

displacing the pre-charge gas back into the pipeline. The

sample gas stays at or near pipeline pressure during the entire

sample period. Laboratories should maintain the pre-charge

pressureduringthesampleanalysissoastomaintainaconstant

pressure on the remaining sample, thus avoiding a phase

FIG. 5 Chart Recorder change due to pressure loss.

D5287 − 08 (2015)

9.1.2 Constant (Fixed) Volume—Variable Pressure (see Fig. HeliumandanalyzingthegasaccordingtoTestMethodD1945

1(b))—These cylinders are commonly referred to as spun end, orTestMethodD5504orothertestmethodusedtomeasurethe

single-cavity vessels. Impact extrusion vessels also fit within analytes of interest. If the remaining contents are known and

this category. If purging is required, connection on each end are considered in the analytic treatment, then further cleaning

would be preferable and can be provided to allow for easier is unn

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5287 − 08 (Reapproved 2015)

Standard Practice for

Automatic Sampling of Gaseous Fuels

This standard is issued under the fixed designation D5287; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice covers the collection of gaseous fuels and

D1945 Test Method for Analysis of Natural Gas by Gas

their synthetic equivalents using an automatic sampler.

Chromatography

1.2 This practice applies only to single-phase gas mixtures.

D5504 Test Method for Determination of Sulfur Compounds

This practice does not address a two-phase stream.

in Natural Gas and Gaseous Fuels by Gas Chromatogra-

phy and Chemiluminescence

1.3 This practice includes the selection, installation, and

2.2 Other Standards:

maintenance of automatic sampling systems.

AGA Report Number 7 Measurement of Gas by Turbine

Meters

1.4 This practice does not include the actual analysis of the

API 14.1 Collecting and Handling of Natural Gas Samples

acquired sample. Other applicable ASTM standards, such as

for Custody Transfer

Test Method D1945, should be used to acquire that informa-

API 14.3 Part 2 (AGA Report Number 3)

tion.

GPA Standard 2166 Methods of Obtaining Natural Gas

1.5 The selection of the sampling system is dependent on

Samples for Analysis by Gas Chromatography

several interrelated factors. These factors include source

ISO-10715 Natural Gas—Sampling Guidelines

dynamics, operating conditions, cleanliness of the source

NACE Standard MR-01-75 Standard Material Require-

gases, potential presence of moisture and hydrocarbon liquids,

ments. Sulfide Stress Cracking Resistant-Metallic Materi-

and trace hazardous components. For clean, dry gas sources, als for Oilfield Equipment

steady source dynamics, and normal operating conditions, the 2.3 Federal Documents:

CFR 49 Code of Federal Regulations, Title 49,173, 34(e), p.

system can be very simple. As the source dynamics become

more complex and the potential for liquids increases, or trace

hazardous components become present, the complexity of the

3. Terminology

system selected and its controlling logic must be increased.

3.1 Definitions of Terms Specific to This Standard:

Similarly, installation, operation, and maintenance procedures

3.1.1 automatic sampler—(see Fig. 1(a) and (b)) a mechani-

must take these dynamics into account.

cal system, composed of a sample probe, sample loop, sample

1.6 The values stated in inch-pound units are to be regarded

extractor, sample vessel, and the necessary logic circuits to

as standard. The values given in parentheses are mathematical

control the system throughout a period of time, the purpose of

conversions to SI units that are provided for information only

and are not considered standard.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1.7 This standard does not purport to address all of the

Standards volume information, refer to the standard’s Document Summary page on

safety concerns, if any, associated with its use. It is the

the ASTM website.

responsibility of the user of this standard to establish appro- Available from American Gas Association, 400 N. Capitol St. N.W.,

Washington, DC 20001, http://www.aga.org/.

priate safety and health practices and determine the applica-

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

bility of regulatory limitations prior to use.

4th Floor, New York, NY 10036, http://www.ansi.org.

Available from Gas Processors Association (GPA), 6526 E. 60th St., Tulsa, OK

74145, http://www.gasprocessors.com.

Available from International Organization for Standardization (ISO), 1, ch. de

This practice is under the jurisdiction of ASTM Committee D03 on Gaseous la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

Fuels and is the direct responsibility of Subcommittee D03.01 on Collection and www.iso.ch.

Measurement of Gaseous Samples. Available from NACE International (NACE), 1440 South Creek Dr., Houston,

Current edition approved June 1, 2015. Published July 2015. Originally approved TX 77084-4906, http://www.nace.org.

in 1992. Last previous edition approved in 2008 as D5287 – 08. DOI: 10.1520/ Available from Superintendent of Documents, Government Printing Office,

D5287-08R15. Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5287 − 08 (2015)

FIG. 1 Continuous Composite Samplers

which is to compile representative samples in such a way that 3.1.7 sample vessel—the container in which the sample is

the final collection is representative of the total composition of collected, stored, and transported to the analytical equipment.

the gas stream for that period of time. This is also referred to as a sample cylinder.

3.1.2 representative sample—a volume of gas that has been 3.1.8 source dynamics—changes in gas supplies, operating

obtained in such a way that the composition of this volume is pressures, temperatures, flow rate, hydrocarbon dew point, and

the same as the total composition of the gas stream from which other factors that may affect composition or state, or both.

it was taken.

4. Significance and Use

3.1.3 retrograde condensation—the formation of liquid

4.1 This practice should be used when and where a repre-

phase by pressure drop or temperature increase on a gas stream

sentative sample is required. A representative sample is neces-

at or below hydrocarbon dew point.

sary for accurate billing in custody transfer transactions,

3.1.4 sample extractor—a device to remove the sample

accurate compositional analysis of the flowing stream, gravity

from the flowing stream or sample loop and put it into the

determination for flow calculations and other desired informa-

sample vessel.

tion concerning the properties of the stream contents.

3.1.5 sample loop—the valve, tubing, or manifold(s), or

4.2 This practice is not intended to preempt existing con-

combination thereof, used for conducting the gas stream from

tract agreements or regulatory requirements.

the probe to the sampling device and back to the source pipe

4.3 Principles pertinent to this practice may be applied in

(or atmosphere).

most contractual agreements.

3.1.6 sample probe—that portion of the sample loop at-

4.4 Warning—Many gages are extremely flammable and

tached to and extending into the pipe containing the gas to be

sampled. can contain toxic substances. Caution should be taken in all

aspects of sample collection and handling. Sample vessels

should only be handled in well ventilated locations away from

9 sparks and flames. Improper handling can result in an explo-

Bergman, D. F., Tek, M. R., and Katz, D. L., Retrograde Condensation in

Natural Gas Pipelines, American Gas Association, Arlington, VA, 1975. sion or injury, or both.

D5287 − 08 (2015)

5. Material Selection

5.1 The sampling system (including probes, tubing, valving

and other components) should be constructed of suitable inert,

or passivated, materials that are compatible with all aspects of

the product and the sampling practice, both internal and

external conditions to ensure that constituents in the fuel

stream do not degrade these components or alter the compo-

sition of the sampled gas.

5.2 The selected material should be inert to and not absorp-

tive of all expected components in the gas stream.

5.3 When sour gas (gases that contain hydrogen sulfide or

carbon dioxide, or both) are present or suspected, consult the

recommendations in NACE Standard MR-01-75.

5.4 Contaminates, other than those listed above, should be

identified and addressed by the appropriate industry

recommendations, guidelines and standards.

6. Sample Probe (see Fig. 2 and Fig. 3)

6.1 The sample probe should be mounted vertically in a

horizontal run.

6.2 The sample probe should penetrate into the center one

third of the pipeline.

6.3 The sample probe should not be located within the

FIG. 3 Probe Locations

defined measurement region. (For example see API 14.3, Part

2, Paragraph 2.5.1).

6.4 The sample probe should be constructed of stainless

steel. (See also, 5.2.)

6.5 The sample probe should be a minimum of five pipe

diameters downstream from any device that could cause

aerosols or significant pressure drop such as orifice plates,

thermowelds, elbows and the like.

6.6 The probe should be designed using probe calculations

with regard to wake frequency and resonant vibration impact.

(See API 14.1, paragraph 7.4.1)

7. Sample Loop (see Fig. 4)

7.1 All valves should be straight bore, full opening, stainless

steel ball valves or full ported valves. In some applications,

specially coated or passivated materials may be required.

FIG. 4 Schematics of Acceptable Sample Loops

7.2 The sample loop should be ⁄4-in. (6.25-mm) or less

outside diameter stainless steel tubing. In some applications,

specially coated or passivated materials may be required.

7.3 The supply line shall slope from the probe up to the

sampler and not possess regions or traps where condensate or

fluid can collect.

7.4 The return line should slope down from the sampler to

a connection of lower pressure on the pipeline and not possess

FIG. 2 Acceptable Probe Types and Installations regions or traps where condensate or fluid can collect.

D5287 − 08 (2015)

7.5 The supply line should be as short as possible, with a extractor adds incremental grabs (samples) to the sample

minimum number of bends. vessel. This only applies to the fixed volume vessels.

8.3.1.2 Electronic Tracing—A magnetic type system can be

7.6 The sample loop should be insulated or heat traced, or

attached to the constant pressure piston style cylinders to track

both, if ambient temperature conditions could cause conden-

the movement of the internal piston during the filling process.

sation of the gas flowing through the loop.

A 4–20 ma signal system (or similar technology) can be

7.7 Filters or strainers that could cause the sample to be

monitored by computer systems or by preset signal verification

biased or altered are not allowed in the sample loop.

process.

7.8 Flow through the sample loop should be verified. 8.3.1.3 Pressure Verification—While not verifying the fill-

ing time frame, a simple test of the cylinder pressure can

8. Automatic Sampler (see Fig. 1(a) and (b))

validate that it was filled to pipeline line pressure.

8.3.2 Verification of Sample Extractor’s Output—Numerous

8.1 Installation—The sampler shall be mounted higher than

devices are available to check the output of the sample

the sample probe. It should be as close to the sample probe as

extractor. The device’s output may be a contact closure, a 4 to

conditions allow. Manufacturer’s specific instructions should

20 mA signal, a power pulse, or any other type that can be

be referenced.

recorded. This applies to all vessel types.

8.2 Maintenance—The sampler should be designed for easy

8.3.3 Pressure Transducer—Like a chart recorder, the pres-

field maintenance. A preventative maintenance schedule as

sure transducer measures the increasing pressure within a fixed

outlined by the manufacturer should be followed.

volume vessel.

8.3 Verification—The sampling personnel should be able to

8.3.4 Calculation Method—When a free-floating piston-

verify that the sample vessel was filled as planned. This can be

type vessel is properly installed with full pipeline pressure on

accomplished by several methods:

the pre-charge side, the only way product can move the piston

8.3.1 Cylinder Filling Verification—See Fig. 5.

is by way of the sample extractor. If the frequency and

8.3.1.1 Chart Recorder—The recorder should be commonly

displacement are known, the piston’s position is verification of

connected to a constant (fixed) volume sample vessel to

proper filling (estimated volume displacement) from the

indicate and record the increased in pressure as the sample

sample extractor and should be equal to the determined

displacement in the free-floating piston vessel. 100 sample

bites, grabs or aliquots of 0.5 cc volume should equal 50 cc in

the cylinder.) Compensation for changes in pipeline pressure

and ambient temperature changes must be considered when

present.

8.4 Control Methods—(see Fig. 1(a) and (b)) Two methods

of controlling samplers are currently recognized:

8.4.1 Proportional-to-Flow Control—This method paces the

sampler with respect to flow. The controller shall be capable of

tracking the pipeline’s flow rate accurately. This method should

be used when the variance of the flow rate is significant or

when flow ceases periodically or is intermittent.

8.4.2 Time-Based Control—This method paces the sample

with respect to time only. Take care to avoid sampling from a

stagnant source. The use of differential pressure switches and

other similar devices may be used to stop the sampling process.

9. Sample Vessels

9.1 Types—There are currently two recognized types, both

of which are in the shape of a cylinder:

9.1.1 Variable Volume—Constant Pressure (see Fig. 1(a))—

These cylinders are commonly manufactured as free-floating

piston configurations. Pipeline pressure is maintained on the

“pre-charge” side of this piston. The sampler connects with the

“product” side of the piston. The sampler pumps the gas into

the product side of the vessel and moves the piston, thus

displacing the pre-charge gas back into the pipeline. The

sample gas stays at or near pipeline pressure during the entire

sample period. Laboratories should maintain the pre-charge

pressure during the sample analysis so as to maintain a constant

pressure on the remaining sample, thus avoiding a phase

FIG. 5 Chart Recorder change due to pressure loss.

D5287 − 08 (2015)

9.1.2 Constant (Fixed) Volume—Variable Pressure (see Fig. Helium and analyzing the gas according to Test Method D1945

1(b))—These cylinders are commonly referred to as spun end, or Test Method D5504 or other test method used to measure the

single-cavity vessels. Impact extrusion vessels also fit within analytes of interest. If the remaining contents are known and

this category. If purging is required, connection on each end are considered in the analytic treatment, then further cleaning

would be preferable and can be provided to allow for easier is unnecessary.

handling

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.