ASTM D5287-08

(Practice)Standard Practice for Automatic Sampling of Gaseous Fuels

Standard Practice for Automatic Sampling of Gaseous Fuels

SIGNIFICANCE AND USE

This practice should be used when and where a representative sample is required. A representative sample is necessary for accurate billing in custody transfer transactions, accurate compositional analysis of the flowing stream, gravity determination for flow calculations and other desired information concerning the properties of the stream contents.

This practice is not intended to preempt existing contract agreements or regulatory requirements.

Principles pertinent to this practice may be applied in most contractual agreements.

Warning—Many gages are extremely flammable and can contain toxic substances. Caution should be taken in all aspects of sample collection and handling. Sample vessels should only be handled in well ventilated locations away from sparks and flames. Improper handling can result in an explosion or injury, or both.

SCOPE

1.1 This practice covers the collection of gaseous fuels and their synthetic equivalents using an automatic sampler.

1.2 This practice applies only to single-phase gas mixtures. This practice does not address a two-phase stream.

1.3 This practice includes the selection, installation, and maintenance of automatic sampling systems.

1.4 This practice does not include the actual analysis of the acquired sample. Other applicable ASTM standards, such as Test Method D 1945, should be used to acquire that information.

1.5 The selection of the sampling system is dependent on several interrelated factors. These factors include source dynamics, operating conditions, cleanliness of the source gases, potential presence of moisture and hydrocarbon liquids, and trace hazardous components. For clean, dry gas sources, steady source dynamics, and normal operating conditions, the system can be very simple. As the source dynamics become more complex and the potential for liquids increases, or trace hazardous components become present, the complexity of the system selected and its controlling logic must be increased. Similarly, installation, operation, and maintenance procedures must take these dynamics into account.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5287 − 08

StandardPractice for

1

Automatic Sampling of Gaseous Fuels

This standard is issued under the fixed designation D5287; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This practice covers the collection of gaseous fuels and

D1945 Test Method for Analysis of Natural Gas by Gas

their synthetic equivalents using an automatic sampler.

Chromatography

1.2 This practice applies only to single-phase gas mixtures.

D5504 TestMethodforDeterminationofSulfurCompounds

This practice does not address a two-phase stream.

in Natural Gas and Gaseous Fuels by Gas Chromatogra-

phy and Chemiluminescence

1.3 This practice includes the selection, installation, and

2.2 Other Standards:

maintenance of automatic sampling systems.

AGA Report Number 7 Measurement of Gas by Turbine

3

Meters

1.4 This practice does not include the actual analysis of the

API 14.1 Collecting and Handling of Natural Gas Samples

acquired sample. Other applicable ASTM standards, such as

4

for Custody Transfer

Test Method D1945, should be used to acquire that informa-

4

API 14.3 Part 2 (AGA Report Number 3)

tion.

GPA Standard 2166 Methods of Obtaining Natural Gas

5

1.5 The selection of the sampling system is dependent on

Samples for Analysis by Gas Chromatography

6

several interrelated factors. These factors include source

ISO-10715 Natural Gas—Sampling Guidelines

dynamics, operating conditions, cleanliness of the source

NACE Standard MR-01-75 Standard Material Require-

gases, potential presence of moisture and hydrocarbon liquids, ments. Sulfide Stress Cracking Resistant-Metallic Materi-

7

and trace hazardous components. For clean, dry gas sources, als for Oilfield Equipment

2.3 Federal Documents:

steady source dynamics, and normal operating conditions, the

CFR 49 Code of Federal Regulations, Title 49,173, 34(e), p.

system can be very simple. As the source dynamics become

8

389

more complex and the potential for liquids increases, or trace

hazardous components become present, the complexity of the

3. Terminology

system selected and its controlling logic must be increased.

3.1 Definitions of Terms Specific to This Standard:

Similarly, installation, operation, and maintenance procedures

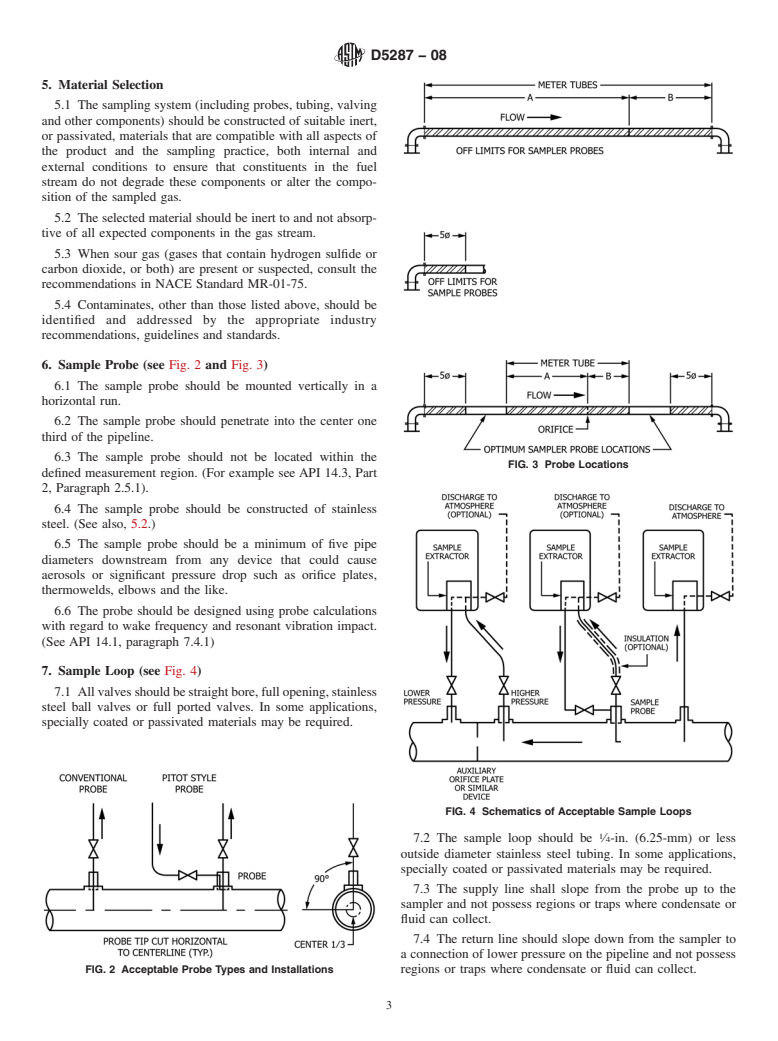

3.1.1 automatic sampler—(seeFig.1(a)and(b))amechani-

must take these dynamics into account.

cal system, composed of a sample probe, sample loop, sample

1.6 The values stated in inch-pound units are to be regarded

extractor, sample vessel, and the necessary logic circuits to

as standard. The values given in parentheses are mathematical

control the system throughout a period of time, the purpose of

conversions to SI units that are provided for information only

and are not considered standard.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1.7 This standard does not purport to address all of the

Standards volume information, refer to the standard’s Document Summary page on

safety concerns, if any, associated with its use. It is the

the ASTM website.

3

responsibility of the user of this standard to establish appro- Available from American Gas Association, 400 N. Capitol St. N.W.,

Washington, DC 20001, http://www.aga.org/.

priate safety and health practices and determine the applica-

4

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

bility of regulatory limitations prior to use.

4th Floor, New York, NY 10036, http://www.ansi.org.

5

Available from Gas ProcessorsAssociation (GPA), 6526 E. 60th St.,Tulsa, OK

74145, http://www.gasprocessors.com.

6

Available from International Organization for Standardization (ISO), 1, ch. de

1

This practice is under the jurisdiction of ASTM Committee D03 on Gaseous la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

Fuels and is the direct responsibility of Subcommittee D03.01 on Collection and www.iso.ch.

7

Measurement of Gaseous Samples. Available from NACE International (NACE), 1440 South Creek Dr., Houston,

Current edition approved Dec. 1, 2008. Published December 2008. Originally TX 77084-4906, http://www.nace.org.

8

approved in 1992. Last previous edition approved in 2002 as D5287 – 97 (2002). Available from Superintendent of Documents, Government Printing Office,

DOI: 10.1520/D5287-08. Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5287 − 08

FIG. 1 Continuous Compo

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5287–97 (Reapproved 2002) Designation: D 5287 – 08

Standard Practice for

1

Automatic Sampling of Gaseous Fuels

This standard is issued under the fixed designation D 5287; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This practice covers the collection of natural gases and their synthetic equivalents using an automatic sampler.

1.2This practice applies only to single-phase gas mixtures that vary in composition.Arepresentative sample cannot be obtained

from a two-phase stream.

1.1 This practice covers the collection of gaseous fuels and their synthetic equivalents using an automatic sampler.

1.2 This practice applies only to single-phase gas mixtures. This practice does not address a two-phase stream.

1.3 This practice includes the selection, installation, and maintenance of automatic sampling systems.

1.4 This practice does not include the actual analysis of the acquired sample. Other applicable ASTM standards, such as Test

Method D 1945, should be referencedused to acquire that information.

1.5 The selection of the sampling system is dependent on several interrelated factors. These factors include source dynamics,

operating conditions, cleanliness of the source gases, potential presence of moisture and hydrocarbon liquids, and trace hazardous

components. For clean, dry gas sources, steady source dynamics, and normal operating conditions, the system can be very simple.

As the source dynamics become more complex and the potential for liquids increases, or trace hazardous components become

present, the complexity of the system selected and its controlling logic must be increased. Similarly, installation, operation, and

maintenance procedures must take these dynamics into account.

1.6The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 1945 Test Method for Analysis of Natural Gas by Gas Chromatography

2.2 Other Standards:

3

AGA Report Number 7 Measurement of Gas by Turbine Meters

4

API 14.1 Collecting and Handling of Natural Gas Samples for Custody Transfer

4

API 14.3 Part 2 (AGA Report Number 3)

5

GPA Standard 2166 Methods of Obtaining Natural Gas Samples for Analysis by Gas Chromatography

6

ISO-10715 Natural Gas—Sampling Guidelines

NACE Standard MR-01-75 Standard Material Requirements. Sulfide Stress Cracking Resistant-Metallic Materials for Oilfield

7

Equipment

1

This practice is under the jurisdiction of ASTM Committee D03 on Gaseous Fuels and is the direct responsibility of Subcommittee D03.01 on Collection and

Measurement of Gaseous Samples.

Current edition approved Nov. 10, 2002.Dec. 1, 2008. Published May 2003.December 2008. Originally approved in 1992. Last previous edition approved in 2002 as

D 5287 – 97 (2002).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 05.06.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Gas Association, 400 N. Capitol St. N.W., Washington, DC 20001, http://www.aga.org/.

4

Available from the American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

5

Available from Gas Processors Association (GPA), 6526 E. 60th St., Tulsa, OK 74145, http://www.gasprocessors.com.

6

Available from National Association of Corrosion Engineers, 1440 South Creek Dr., Houston, TX 77084.

6

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

7

Available from Superintendent of Documents, Government Printing Office, Washington, DC 20402.

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5287–97 (Reapproved 2002) Designation: D 5287 – 08

Standard Practice for

1

Automatic Sampling of Gaseous Fuels

This standard is issued under the fixed designation D 5287; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This practice covers the collection of natural gases and their synthetic equivalents using an automatic sampler.

1.2This practice applies only to single-phase gas mixtures that vary in composition.Arepresentative sample cannot be obtained

from a two-phase stream.

1.1 This practice covers the collection of gaseous fuels and their synthetic equivalents using an automatic sampler.

1.2 This practice applies only to single-phase gas mixtures. This practice does not address a two-phase stream.

1.3 This practice includes the selection, installation, and maintenance of automatic sampling systems.

1.4 This practice does not include the actual analysis of the acquired sample. Other applicable ASTM standards, such as Test

Method D 1945, should be referencedused to acquire that information.

1.5 The selection of the sampling system is dependent on several interrelated factors. These factors include source dynamics,

operating conditions, cleanliness of the source gases, potential presence of moisture and hydrocarbon liquids, and trace hazardous

components. For clean, dry gas sources, steady source dynamics, and normal operating conditions, the system can be very simple.

As the source dynamics become more complex and the potential for liquids increases, or trace hazardous components become

present, the complexity of the system selected and its controlling logic must be increased. Similarly, installation, operation, and

maintenance procedures must take these dynamics into account.

1.6The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 1945 Test Method for Analysis of Natural Gas by Gas Chromatography

2.2 Other Standards:

3

AGA Report Number 7 Measurement of Gas by Turbine Meters

4

API 14.1 Collecting and Handling of Natural Gas Samples for Custody Transfer

4

API 14.3 Part 2 (AGA Report Number 3)

5

GPA Standard 2166 Methods of Obtaining Natural Gas Samples for Analysis by Gas Chromatography

6

ISO-10715 Natural Gas—Sampling Guidelines

NACE Standard MR-01-75 Standard Material Requirements. Sulfide Stress Cracking Resistant-Metallic Materials for Oilfield

7

Equipment

1

This practice is under the jurisdiction of ASTM Committee D03 on Gaseous Fuels and is the direct responsibility of Subcommittee D03.01 on Collection and

Measurement of Gaseous Samples.

Current edition approved Nov. 10, 2002.Dec. 1, 2008. Published May 2003.December 2008. Originally approved in 1992. Last previous edition approved in 2002 as

D 5287 – 97 (2002).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 05.06.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Gas Association, 400 N. Capitol St. N.W., Washington, DC 20001, http://www.aga.org/.

4

Available from the American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

5

Available from Gas Processors Association (GPA), 6526 E. 60th St., Tulsa, OK 74145, http://www.gasprocessors.com.

6

Available from National Association of Corrosion Engineers, 1440 South Creek Dr., Houston, TX 77084.

6

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

7

Available from Superintendent of Documents, Government Printing Office, Washington, DC 20402.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.