ASTM D3451-06(2017)

(Guide)Standard Guide for Testing Coating Powders and Powder Coatings

Standard Guide for Testing Coating Powders and Powder Coatings

SIGNIFICANCE AND USE

4.1 This guide provides a useful summary to the selection and use of procedures for testing coating powders and powder coatings. It is applicable to both thermoplastic and thermoset coatings, unless indicated otherwise. By design this guide does not purport to address test methods or procedures developed specifically for the functional powder coating market, those coating powders for application to pipe or reinforced steel bars (rebar). Information on current test procedures for pipe and reinforced steel bar coating powders and powder coatings can be obtained through their respective ASTM Subcommittees, A01.05 and D01.48.

4.2 Selection of the methods to be followed and the interpretation of results must be governed by experience and the requirements in each individual case, together with agreement between the purchaser and seller. It should be noted that many of the methods used for characterizing a coating powder, such as gel time (Section 16) and inclined flow (Section 17), are primarily meant for the relative comparison of two coating powders, rather than to give a test value that can be interpreted as good or bad. Interpretation of the test results will depend on the specific application in question and will also often depend on the chemistry of the coating powder used.

SCOPE

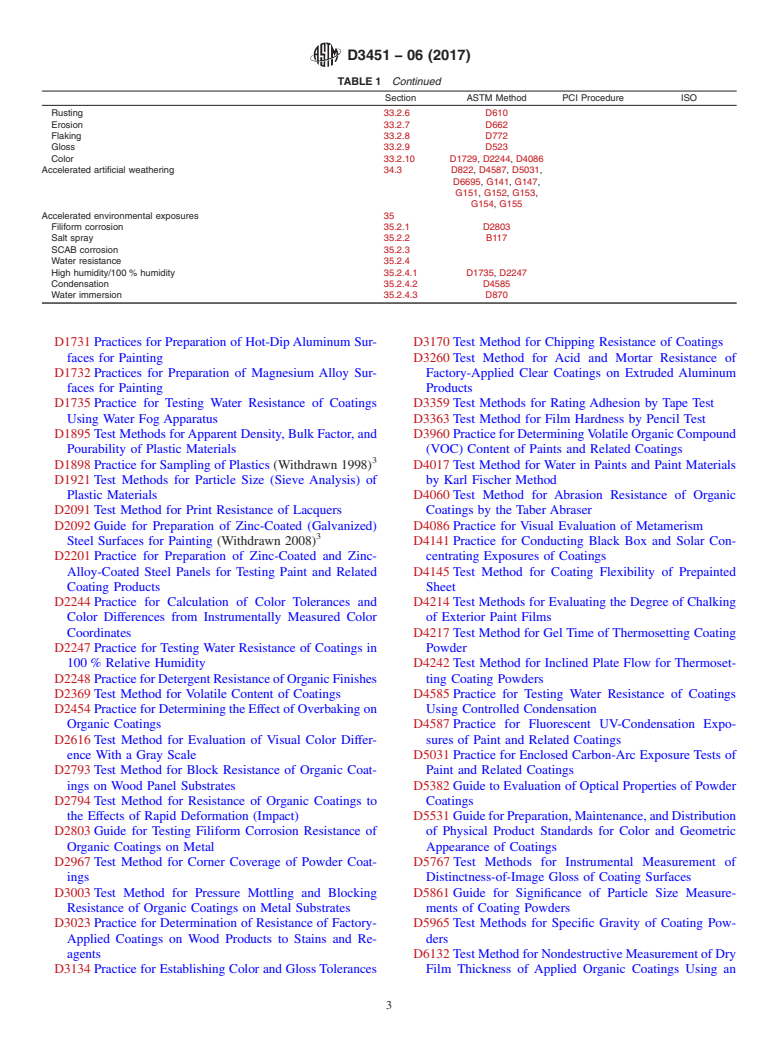

1.1 This guide covers the selection and use of procedures for testing coating powders and powder coatings. The test methods included are listed in Table 1. Where more than one test method is listed for the same characteristic, no attempt is made to indicate superiority of one method over another. Selection of the methods to be followed must be governed by experience and the requirements in each individual case, together with agreement between the purchaser and the seller.

1.2 This guide also refers to methods developed specifically for the coating powder industry by the Powder Coating Institute, PCI, and the International Organization for Standards, ISO.

1.3 This guide describes the testing of coating powders as applied by electrostatic spray, fluidized bed, or any other applicable method.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3451 − 06 (Reapproved 2017)

Standard Guide for

1

Testing Coating Powders and Powder Coatings

This standard is issued under the fixed designation D3451; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D522 Test Methods for Mandrel Bend Test of Attached

Organic Coatings

1.1 This guide covers the selection and use of procedures

D523 Test Method for Specular Gloss

for testing coating powders and powder coatings. The test

D609 Practice for Preparation of Cold-Rolled Steel Panels

methods included are listed in Table 1. Where more than one

for Testing Paint, Varnish, Conversion Coatings, and

test method is listed for the same characteristic, no attempt is

Related Coating Products

made to indicate superiority of one method over another.

D610 Practice for Evaluating Degree of Rusting on Painted

Selection of the methods to be followed must be governed by

Steel Surfaces

experience and the requirements in each individual case,

D658 Test Method for Abrasion Resistance of Organic

together with agreement between the purchaser and the seller.

3

Coatings by Air Blast Abrasive (Withdrawn 1996)

1.2 This guide also refers to methods developed specifically

D660 Test Method for Evaluating Degree of Checking of

for the coating powder industry by the Powder Coating

Exterior Paints

Institute, PCI, and the International Organization for

D661 Test Method for Evaluating Degree of Cracking of

Standards, ISO.

Exterior Paints

1.3 This guide describes the testing of coating powders as

D662 Test Method for Evaluating Degree of Erosion of

applied by electrostatic spray, fluidized bed, or any other

Exterior Paints

applicable method.

D714 Test Method for Evaluating Degree of Blistering of

Paints

1.4 The values stated in SI units are to be regarded as

D772 Test Method for Evaluating Degree of Flaking (Scal-

standard. No other units of measurement are included in this

ing) of Exterior Paints

standard.

D822 Practice for Filtered Open-Flame Carbon-Arc Expo-

1.5 This standard does not purport to address all of the

sures of Paint and Related Coatings

safety concerns, if any, associated with its use. It is the

D870 Practice for Testing Water Resistance of Coatings

responsibility of the user of this standard to establish appro-

Using Water Immersion

priate safety and health practices and determine the applica-

D968 Test Methods for Abrasion Resistance of Organic

bility of regulatory limitations prior to use.

Coatings by Falling Abrasive

1.6 This international standard was developed in accor-

D1005 Test Method for Measurement of Dry-Film Thick-

dance with internationally recognized principles on standard-

ness of Organic Coatings Using Micrometers

ization established in the Decision on Principles for the

D1014 Practice for Conducting Exterior Exposure Tests of

Development of International Standards, Guides and Recom-

Paints and Coatings on Metal Substrates

mendations issued by the World Trade Organization Technical

D1308 Test Method for Effect of Household Chemicals on

Barriers to Trade (TBT) Committee.

Clear and Pigmented Organic Finishes

2. Referenced Documents D1474 Test Methods for Indentation Hardness of Organic

2

Coatings

2.1 ASTM Standards:

D1535 Practice for Specifying Color by the Munsell System

B117 Practice for Operating Salt Spray (Fog) Apparatus

D1654 Test Method for Evaluation of Painted or Coated

Specimens Subjected to Corrosive Environments

1

This guide is under the jurisdiction of ASTM Committee D01 on Paint and

Related Coatings, Materials, and Applications and is the direct responsibility of D1729 Practice for Visual Appraisal of Colors and Color

Subcommittee D01.51 on Powder Coatings.

Differences of Diffusely-Illuminated Opaque Materials

Current edition approved June 1, 2017. Published June 2017. Originally

D1730 Practices for Preparation of Aluminum and

approved in 1975. Last previous edition approved in 2012 as D3451 – 06 (2012).

Aluminum-Alloy Surfaces for Painting

DOI: 10.1520/D3451-06R17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

----------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.