ISO 6452:2000

(Main)Rubber- or plastics-coated fabrics — Determination of fogging characteristics of trim materials in the interior of automobiles

Rubber- or plastics-coated fabrics — Determination of fogging characteristics of trim materials in the interior of automobiles

Supports textiles revêtus de caoutchouc ou de plastique — Détermination des caractéristiques de ternissement des matériaux constitutifs des garnitures utilisées dans l'habitacle des automobiles

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 6452

First edition

2000-07-01

Rubber- or plastics-coated fabrics —

Determination of fogging characteristics of

trim materials in the interior of automobiles

Supports textiles revêtus de caoutchouc ou de plastique — Détermination

des caractéristiques de ternissement des matériaux constitutifs des

garnitures utilisées dans l'habitacle des automobiles

Reference number

ISO 6452:2000(E)

©

ISO 2000

---------------------- Page: 1 ----------------------

ISO 6452:2000(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2000

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 � CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 2000 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 6452:2000(E)

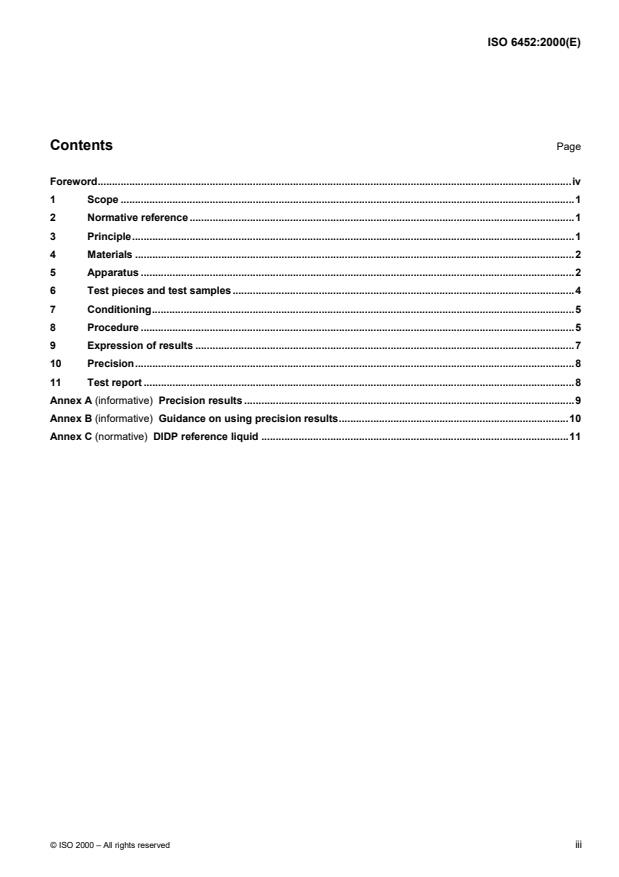

Contents Page

Foreword.iv

1 Scope .1

2 Normative reference .1

3 Principle.1

4 Materials .2

5 Apparatus .2

6 Test pieces and test samples.4

7 Conditioning.5

8 Procedure .5

9 Expression of results .7

10 Precision.8

11 Test report .8

Annex A (informative) Precision results .9

Annex B (informative) Guidance on using precision results.10

Annex C (normative) DIDP reference liquid .11

© ISO 2000 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 6452:2000(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 6452 was prepared by Technical Committee ISO/TC 45, Rubber and rubber products.

Annex C forms a normative part of this International Standard. Annexes A and B are for information only.

iv © ISO 2000 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 6452:2000(E)

Rubber- or plastics-coated fabrics — Determination of fogging

characteristics of trim materials in the interior of automobiles

WARNING — Persons using this International Standard should be familiar with normal laboratory practice.

This standard does not purport to address all of the safety problems, if any, associated with its use. It is

the responsibility of the user to establish appropriate safety and health practices and to ensure compliance

with any national regulatory conditions.

1 Scope

This International Standard specifies a test method which is intended to determine the fogging characteristics of

rubber- or plastics-coated fabrics that are used as trim materials in the interior of motor vehicles.

The method may also be applicable to fluid, pasty, powdered or solid raw materials which are the basis for such

trim materials or from which the materials are manufactured. The method may also be applicable to other materials

and finished products.

The procedure is applicable to the measurement of fog condensate on glass surfaces within the limits of the test

conditions. This test will not measure or cannot measure accurately those cases in which:

� the surface tension of the condensate is low, resulting in early coalescing into a thin transparent film;

� the condensate is present in such a large quantity that the droplets coalesce and form a heavy oily/clear film

(this heavy film gives false readings).

2 Normative reference

The following normative document containd provisions which, through reference in this text, constitute provisions of

this International Standard. For dated references, subsequent amendments to, or revisions of, this publication do

not apply. However, parties to agreements based on this International Standard are encouraged to investigate the

possibility of applying the most recent edition of the normative document indicated below. For undated references,

the latest edition of the normative document referred to applies. Members of ISO and IEC maintain registers of

currently valid International Standards.

ISO/TR 9272:1986, Rubber and rubber products — Determination of precision for test method standards.

3Principle

A test piece is heated in a glass beaker. Any volatile constituents are condensed on either a cooled glass plate or a

disc of cooled aluminium foil.

The fogging value F is calculated as the quotient, in percent, of the reflectometer value for the glass plate with

fogging condensate and the reflectometer value of the same glass plate without fogging condensate.

The mass of the condensable constituents G is given by the difference between the masses of the aluminium foil

disc with and without fogging.

© ISO 2000 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO 6452:2000(E)

4 Materials

4.1 Thermal-transfer fluid, for the thermostatically controlled bath (5.1). The fluid shall be temperature-stable

and preferably water-soluble for easier cleaning. A suitable fluid is a modified polyhydric aliphatic alcohol.

4.2 Glass-cleaning detergent, of a non-alkaline type.

4.3 Test fluid, for checking the cleanliness of the glass plates (5.6), consisting of a methanol-water mixture

containing 27,1 % of methanol (PA quality) and 72,9 % of distilled water by volume and having a surface tension of

46 mN/m. About 1 g of a soluble red dye (e.g. fuchsin) can be added to 1 litre of the test fluid for easier detection.

4.4 Diisodecyl phthalate (DIDP), obtained from the stated source (see annex C).

5 Apparatus

5.1 Thermostatically controlled bath, designed to operate at up to 130 °C. Safety devices shall be fitted to

prevent overheating. The circulation system, the bath capacity and the heating system shall be such that the

temperature can be kept constant to within� 0,5 °C throughout the bath.

The bath shall be designed so that, after placing the beakers (5.3) in the bath, the temperature does not drop more

than 5 °C, and the test temperature is regained after no more than 20 min. The minimum distance between the

beakers and the walls shall be 30 mm and between the bottom of the bath and the beakers 60 mm.

The bath shall be equipped with a device indicating the distance between the bath fluid and the lower surface of the

glass plate (5.6). This distance shall be (60� 2) mm.

5.2 Cooling plates, designed to be placed on the glass plates (5.6) to keep them cool. The cooling plates shall

be hollow and made of corrosion-resistant metal, with the side facing the glass plate made of aluminium. They shall

have two cooling-water connections located so that the cooling water flows through the whole of the interior of the

plate. The surface in contact with the glass plate shall be flat. The mass of a cooling plate filled with water shall be

at least 1 kg, to overcome the buoyancy of the beaker (5.3) in the bath. The whole of the weight of the cooling plate

shall rest on the beaker. A separate cooling plate shall be used for each beaker.

The cooling plates and the associated water thermostat shall be designed so that the mean water temperature is

21 °C and the difference in temperature between the inlet and outlet does not exceed 1 °C.

5.3 Flat-bottomed beakers, of heat-resistant glass, minimum mass 450 g, with the dimensions shown in

Figure 1.

5.4 Metal rings, external diameter 80 mm, internal diameter 74 mm, height 10 mm and mass (55� 1) g, made of

corrosion-protected steel, to keep the test pieces flat.

5.5 Sealing rings, of silicone- or fluoro-rubber, L-shaped or circular in cross-section, inner diameter 90 mm to

95 mm, thickness 2 mm to 4 mm and hardness 60 IRHD to 70 IRHD.

5.6 Float-glass plates, of residential or windshield window quality, for condensation of the fogging, thickness

(3� 0,2) mm, either square with minimum dimensions of (110� 110) mm or circular with a diameter of 103 mm.

The reflectometer values of all the plates used shall be the same to within� 2 % units. The tin and non-tin surfaces

of the plates shall be identified.

NOTE The tin and non-tin surfaces of the glass plates can be identified by viewing the surfaces in a darkened room under

a UV light at 254 nm wavelength. The tin surface will fluoresce when it is exposed to the UV light.

2 © ISO 2000 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 6452:2000(E)

Dimensions in millimetres

Figure 1 — Glass beaker

2

5.7 Filter paper, with a diameter of 110 mm and a mass per unit surface area of 90 g/m .

5.8 Aluminium foil discs, thickness 0,03 mm, diameter (103� 1) mm.

© ISO 2000 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO 6452:2000(E)

5.9 Reflectometer,witha60° incident beam and 60° measurement beam.

5.10 Spacer, designed to prevent contact with the condensate on the glass plate during reflectometer

measurements, made of a suitable material such as paper or plastic with a circular hole for the measurements. The

thickness of the spacer shall be (0,1� 0,02) mm (see Figure 2).

Dimensions in millimetres

Figure 2 — Spacer on top of glass plate

5.11 Dishwasher, preferably connected to a deionized-water supply and capable of being operated at 80 °C.

5.12 Balance, with scale divisions of 0,01 mg.

5.13 Polyethylene gloves.

6 Test pieces and test samples

In the case of finished products, cut circular test pieces with a diameter of (80� 1) mm from the sample. The

thickness of the test pieces can be up to 10 mm. Machine thicker materials on the underside to 10 mm (the

underside is the side facing away from the side which is visible in the vehicle). If other test piece dimensions are

required, these may be as given in the product specification or as agreed between the interested parties.

In the case of powdered, pasty or fluid materials, take a test sample of (10� 0,1) g.

Take two test pieces or test samples for the determination of the fogging value F and another two for the

determination of the mass of the condensable constituents G.

4 © ISO 2000 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 6452:2000(E)

7 Conditioning

Unless otherwise specified, condition all test pieces and test samples at 23 °C and 50 % RH for at least 16 h.

Foamed materials and coated fabrics shall be conditioned by drying in accordance with Table 1 in a desiccator over

phosphorus pentoxide (or silica gel) on a carrier, without the use of a vacuum.

Table 1 — Drying times

Drying time

Material

days

Foamed materials 1

Coated fabrics 2

8 Procedure

8.1 Cleaning

8.1.1 General

Only touch the beakers (5.3) on the outer surfaces.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.