ISO 1496-1:1974

(Main)Title missing - Legacy paper document

Title missing - Legacy paper document

General Information

Standards Content (Sample)

INTERNATIONAL STANDARD 149611

~

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION .MEXLIYHAPOlUiAR OPïAHH3AWR no CTAHMI"3AUHH .ORGANISATION INTERNATIONALE DE NORMAUSATION

Series 1 freight containers - Specification and testing -

Part I : General cargo containers

Conteneurs de la série 1 - Spécifications et essais - Partie I : Conteneurs pour usage générai

First edition - 1974-04-01

-

- UDC 621.869.88 Ref. No. IS0 1496/1-1974 (E)

z

y

- kscriptorr : freight containers, specifications, tests, dimensions, ratings, design.

ù3

Q>

P

Price based on 13 pages

s

---------------------- Page: 1 ----------------------

FOREWORD

IS0 (the International Organization for Standardization) is a worldwide federation

of national standards institutes (IS0 Member Bodies). The work of developing

International Standards is carried out through IS0 Technical Committees. Every

Member Body interested in a subject for which a Technical Committee has been set

up has the right to be represented on that Committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work.

Draft International Standards adopted by the Technical Committees are circulated

to the Member Bodies for approval before their acceptance as International

Standards by the IS0 Council.

International Standard IS0 1496/1 (originally Draft International Standard

iSO/DiS 2973) was drawn up by Technical Committee ISO/TC 104, Freight

containers, and circulated to the Member Bodies in October 1972.

It has been approved by the Member Bodies of the following countries :

Australia Germany Romania

Austria Hungary South Africa, Rep. of

Belgium India Sweden

Brazil Israel Switzerland

Bulgaria Thailand

Japan

Netherlands Turkey

Canada

Czechoslovakia New Zealand United Kingdom

Egypt, Arab Rep. of Poland U.S.A.

France Portugal U.S.S. R.

This International Standard has also been approved by the International Union of

Railways (UIC).

No Member Body expressed disapproval of the document.

International Standard IS0 1496, parts I to VII, cancels and replaces IS0

Recommendation R 1496-1970.

O International Organization for Standardization, 1974

Printed in Switzerland

---------------------- Page: 2 ----------------------

e

IS0 1496/1-1974 (E)

INTERNATIONAL STANDARD

Series 1 freight containers - Specification and testing -

Part I : General cargo containers

1.2 The container types covered by this International

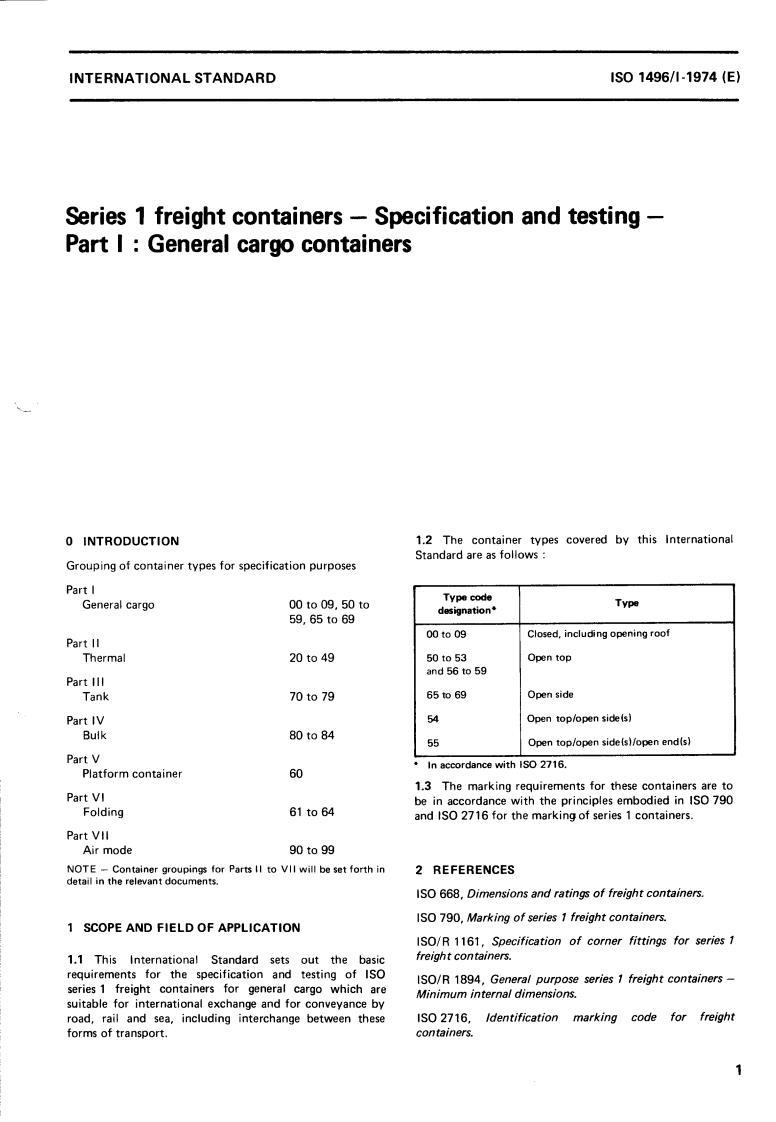

O INTRODUCTION

Standard are as follows :

Grouping of container types for specification purposes

I

Part

General cargo O0 to 09, 50 to Type

designation" I I

59,65 to 69

Closed, including opening roof

O0 to O9

Part II

Thermal 20 to 49 50 to 53 Open top

and 56 to 59

Part III

Open side

65 to 69

Tank 70 to 79

Open top/open side(s)

54

Part IV

Bulk 80 to 84

Open toplopen side(s)/open endk)

55

Part V

Platform container 60

Part VI

Folding 61 to 64

Part VI I

Air mode 90 to 99

NOTE - Container groupings for Parts II to VI1 will be set forth in

2 REFERENCES

detail in the relevant documents.

IS0 668, Dimensions and ratings of freight containers.

IS0 790, Marking of series 1 freight containers.

1 SCOPE AND FIELD OF APPLICATION

I SO/ R 1 161 , Specification of corner fittings for series 1

freight con tainers.

1.1 This International Standard sets out the basic

requirements for the specification and testing of IS0

ISOIR 1894, General purpose series 1 freight containers -

series 1 freight containers for general cargo which are

Minimum internal dimensions.

suitable for international exchange and for conveyance by

road, rail and sea, including interchange between these IS0 2716, Identification marking code for freight

con tainers.

forms of transport.

1

---------------------- Page: 3 ----------------------

IS0 1496/1-1974 (E)

All closed containers and all open containers fitted with the

3 DIMENSIONS AND RATINGS

covers which were designed for them, shall be weatherproof

as required by test number 13 (see 5.14).

3.1 External dimensions

The overall external dimensions and tolerances of the

4.2 Corner fittings

freight containers covered by this International Standard

All series 1 containers shall be equipped with corner fittings

are those established in IS0 668. No aprt of the container

at the top corners. 1 AA, 1 A, 1 B, 1C and 1 D containers

shall project beyond these overall external dimensions.

shall, in addition, be equipped with corner fittings at the

bottom corners. The requirements and positioning of the

3.2 Internal dimensions

ISO/R 1161. The upper faces of

corner fittings are given in

Internal dimensions of containers shall be as large as the top corner fittings shall protrude above the top of the

container by a minimum of 6 mm (1/4 in) (see 4.3.3). The

possible, but, in any case,

“top of the container” means the highest level of the cover

- closed containers type O0 shall comply with the

of the container, for example the level of the top of a soft

minimum internal length, width and height given in

cover.

ISO/R 1894;

4.3 Base structure

- containers type 02, having partial opening(s) in the

side(s), shall comply with the minimum internal length

4.3.1 For containers lAA, 1A. 1B and 1C. the height of

and height given in ISO/R 1894;

the lower faces of all transverse members in the base of the

- containers type 03, having an opening roof, shall

containers (including end transverse members) above the

comply with the minimum internal length and width

base plane (bottom faces of lower corner fittings) shall be

ISO/R 1894;

given in

12.5 1;; mm (1/2 1;:: in).

- containers types01 and 04, having openings in the

side(s) and/or roof, shall comply with the minimum

4.3.2 For containers lD, 1E and 1F the level of the

internal length given in ISO/R 1894.

underside of the base structure is not specified, except in so

far as it is implied in 4.3.3.

3.3 Ratings

4.3.3 For series 1 containers under dynamic conditions, or

The values of the rating R, being the maximum operating

the static equivalent thereof, with the container having a

gross weight of the container, are those given in IS0 668.

load uniformly distributed over the floor in such a way that

the combined weight of the container and test load is equal

R=P+T

to 1,8 R, no part of the base of the container shall deflect

more than 6 mm (1/4 in) below the base plane (bottom

where P is the maximum operating playload and T is the

faces of the lower corner fittings).

tare weight.

4.4 End structure

4 DESIGN REQUIREMENTS For containers lAA, lA, 1B and 1C. the sideways

deflection of the top of the container with respect to the

bottom of the container at the time it is under full

4.1 General

transverse rigidity test conditions, shall not cause the sum

All containers shall be capable of fulfilling the following

of the changes in length of the two diagonals to exceed

requirements.

60 mm (2 3/8 in).

The strength requirements for containers are given in

4.5 Side structure

diagrammatic form in annex A (these requirements are

applicable to all containers except where otherwise stated).

For containers 1AA. lA, 1B and lC, the longitudinal

They apply to containers as complete units.

deflection of the top of the container with respect to the

bottom of the container at the time it is under full

The strength requirements for corner fittings (see also 4.2)

longitudinal rigidity test conditions shall not exceed 25 mm

are given in annex C of ISO/R 11 61.

(1 in).

The container shall be capable of withstanding the loads

and applied forces detailed in clause 5.

4.6 Walls

As the effects of loads encountered under any dynamic

Where openings are provided in end or side walls, the ability

operating condition should only approach, but not exceed,

of these walls to withstand tests numbers 5 and 6 shall not

the effects of the corresponding test loads, it is implicit that

be impaired.

the capabilities of containers indicated in annex A and

demonstrated by the tests described in clause 5 shall not be Where containers (other than closed containers) are

provided with end(s) or side(s) which are not able to

exceeded in any mode of operation.

2

---------------------- Page: 4 ----------------------

IS0 1496/1-1974 (E)

withstand tests numbers 5 and 6, means shall be provided

5 TESTING

for securing the cargo to the base structure in such a

manner that the cargo does not transmit forces to the ends

5.1 General

or sides.

Unless otherwise stated, containers complying with the

Where containers do not have end or side walls, means shall

design requirements specified in clause 4 shall, in addition,

be provided for securing the cargo to the base structure.

be capable of withstanding the tests specified in 5.2 to 5.14

inclusive, as applicable. It is recommended that the test for

4.7 Door opening

weatherproofness (Test No. 13) be made last.

Each container, except those containers with open ends,

5.1.1 The symbol R denotes the maximum operating gross

shall be provided with a door opening at least at one end,

weight of the container and the symbol P denotes the

except in the case of 1E and 1F containers, where the

maximum operating payload of the container to be tested,

opening may be provided in a side wall.

that is, the tare weight T subtracted from the maximum

Closed-type containers designated 1A. lB, 1C and 1D

operating gross weight R.

(types O0 and 02) shall have a door opening, preferably

having dimensions equal to those of the internal R=P+T

cross-section of the containers and, in any case, not less

5.1.2 The test load within the container shall be uniformly

than 2 134 mm (7 ft O in) high and 2 286 mm (7 ft 6 in)

L

distributed.

wide.

NOTE - Water is recommended as the test medium to determine

Closed-type containers designated 1AA (types O0 and 02)

the ability of the ehd and side walls, test numbers 5 and 6, to with-

shall have a door opening, preferably having dimensions

stand the resultant forces imposed by cargo on these members.

Other methods which produce loading equivalent to a fluid load in

equal to those of the internal cross-section of the

mass and distribution (for example, dry sand in loose bulk or in

case, not less than 2 261 mm

containers, and, in any

bags free to flex) may be used at the discretion of the test engineer.

(7 ft 5 in) high, and 2 286 mm (7 ft 6 in) wide.

All door openings and end openings shall be as large as 5.1.3 The test loads specified in all of the following tests

possi ble. are the minimum requirements.

OPTIONAL R EQUlR EMENTS 5.1.4 The dimensional requirements to which reference is

made in the requirements sub-clause after each test are

those specified in :

4.8 Fork lift pockets

a) the dimensional and design requirement clauses of

Fork lift pockets may be provided as optional features for

this International Standard;

handling lC, 1D. 1 E and 1 F containers in the loaded or

unloaded condition. The dimensional requirements for such

b) iSO668;

pockets are specified in annex B.

c) ISOiR 1161.

Fork pockets, when provided, shall pass completely through

the base structure of the container, so that lifting devices

(.-

5.2 Test No. 1 - Stacking

may be inserted from either side.

It is not necessary for the base of the fork lift pockets to be

5.2.1 General

the full width of the container, but it should be provided in

This test shall be carried out to prove the ability of a

the vicinity of each end.

container to support five other fully loaded containers of

the same length and rating under the acceleration

4.9 Provision for handling at the base by means of

conditions encountered in ships’ cell structures, taking into

grappler arms or similar devices

account relative eccentricities between containers due to

Provision for handling 1 AA, 1 A, 16, 1 C and 1 D containers

clearance.

by means of grappler arms or similar devices may be

provided as optional features. The dimensional

5.2.2 Procedure

requirements for such provisions are specified in annex C.

The container under test shall be placed on four level pads,

one under each bottom corner fitting or equivalent corner

4.10 Gooseneck tunnels

structure. The pads shall be centralized under the fittings,

Gooseneck tunnels may be provided as optional features in

as the

and be substantially of the same plan dimensions

containers 1 AA and 1 A. The dimensional requirements are

fittings. The container shall have a load uniformly

specified in annex D and, in addition, all other parts of the

distributed over the floor in such a way that the combined

base structure shall be as specified in 4.3.

weight of the container and the test load is equal to 1,8 R.

NOTE - The requirements of 4.2, 4.8 and 4.9 do not preclude the

The container under test shall be subjected to a vertical

provision of additional facilities for lifting, either from the top or at

force of 2,25 R on each of the top corner fittings

the bottom of the containers.

---------------------- Page: 5 ----------------------

IS0 1496/l -1974 (E)

simultaneously or 4,5 R on each pair of end fittings in such

5.4 Test No. 3 - Lifting from the bottom corner fittings

a manner that the planes of application of the forces and

the supports of the container remain horizontal and

5.4.1 General

unchanged during the test. The forces shall be applied

This test shall be carried out to prove the ability of

through a corner fitting or a pad of the same plan area as a

containers to withstand being lifted from bottom corner

corner fitting. Each pad shall be offset in the same direction

fittings by means of lifting devices bearing on the bottom

by 25.4 mm (1 in) laterally and 38mm (1 1/2 in)

corner fittings only and attached to a single transverse

longitudinally.

central spreader beam, above the container.

This test shall be carried out on IAA, 1A. lB, 1C and 1D

5.2.3 Requirements

containers. It shall also be carried out on 1E and 1F

Upon completion of the test, the container shall show

containers if they are equipped with bottom corner fittings.

neither permanent deformation which will render it

unsuitable for use nor abnormality which will render it

5.4.2 Procedure

unsuitable for use, and the dimensional requirements

affecting handling, securing and interchange shall be

The container under test shall have a load uniformly

satisfied.

distributed over the floor in such a way that the combined

weight of container and test load is equal to 2 R, and it

shall be carefully lifted from the side apertures of all four

5.3 Test No. 2 - Lifting from the top corner fittings

bottom corner fittings in such a way that no significant

acceleration or deceleration forces are applied.

5.3.1 General

Lifting forces shall be applied at :

This test shall be carried out to prove the ability of lAA,

30" to the horizontal for 1AA and 1A containers;

lA, 1B and 1C containers to withstand being lifted from

the top corner fittings with the lifting forces applied

37" to the horizontal for 1 B containers;

vertically, and the ability of 1 D, 1 E and 1 F containers to

withstand being lifted from the top corner fittings with the

45" to the horizontal for 1 C containers;

lifting forces applied at any angle between the vertical and

60" to the horizontal for 1 D, 1 E and 1 F containers.

30" to the vertical, these being the only recognized

methods of lifting these containers by the top corner

In each case the line of action of the lifting force and the

fittings.

outer face of the corner fitting shall be no farther apart

than 38 mm (1 1/2 in). The lifting shall be carried out in

This test shall also be regarded as proving the ability of the

such a manner that the lifting devices bear on the bottom

floor and base structure to withstand the forces arising

corner fittings only.

from acceleration of the payload in lifting operations.

The container shall be suspended for 5min and then

lowered to the ground.

5.3.2 Procedure

The container under test shall have a load uniformly

5.4.3 Requirements

distributed over the floor in such a way that the combined

weight of the container and test load is equal to 2 R, and it

Upon completion of the test, the container shall show

shall be carefully lifted from all four top corners in such a

neither permanent deformation which will render it

way that no significant acceleration or deceleration forces

unsuitable for us

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.