EN 14592:2008+A1:2012

(Main)Timber structures - Dowel-type fasteners - Requirements

Timber structures - Dowel-type fasteners - Requirements

This European Standard specifies the requirements and test methods for materials, geometry, strength, stiffness and durability ascpects (i.e. corrosion protection) of dowel-type fasteners for use in load bearing timber structures.

Only dowel-type fasteners manufactured from steel are covered by this European Standard. For the purpose of this standard, dowel-type fasteners for timber structures are taken to be nails, staples, screws, dowels, and bolts with nuts. Definitions of these items are given in Clause 3. This European Standard specifies also the evaluation of conformity procedures and includes requirements for marking of these products.

This European Standard does not cover resin coated dowel-type fasteners and fasterners treated with fire retardants to improve their fire performance. It also does not cover resin coated fasteners.

Holzbauwerke - Stiftförmige Verbindungsmittel - Anforderungen

Diese Europäische Norm legt die Anforderungen an und Prüfverfahren für die Werkstoffe, die Geometrie, die

Festigkeit, die Steifigkeit und die Dauerhaftigkeit (d. h. den Korrosionsschutz) von stiftförmigen Verbindungsmitteln

zum Einsatz in tragenden Holzbauwerken fest. Die vorliegende Europäische Norm deckt nur stiftförmige Verbindungsmittel ab, die aus Stahl hergestellt werden. Für die Anwendung dieser Norm umfassen stiftförmige Verbindungsmittel für Holzbauwerke Nägel,

Klammern, Schrauben, Stabdübel und Bolzen mit Muttern. Die Definitionen dieser Elemente sind in Abschnitt 3 angegeben. Die vorliegende Europäische Norm legt auch die Verfahren zur Bewertung der Konformität dieser Erzeugnisse fest und enthält Anforderungen an deren Kennzeichnung. Diese Europäische Norm deckt keine Verbindungsmittel ab, die mit Flammschutzmitteln behandelt

wurden, um deren Brandverhalten zu verbessern. Diese Europäische Norm umfasst Verbindungsmittel, die zu folgenden Zwecken behandelt werden dürfen:

1) Korrosionsschutz (z. B. Feuerverzinkung und Epoxydharzüberzug);

2) Gleitschicht (um das Eintreiben/Eindrehen zu erleichtern);

3) Erhöhung der Ausziehfestigkeit und/oder Magazinierung (Klebeüberzug).

Structures en bois - Eléments de fixation de type tige - Exigences

La présente Norme européenne spécifie les exigences et méthodes d’essai des matériaux ainsi que des aspects géométriques, de résistance, de rigidité et de durabilité (c’est-à-dire la protection contre la corrosion) des éléments de fixation pour l’utilisation dans des structures portantes en bois.

Seuls les éléments de fixation fabriqués en acier sont couverts par la présente norme européenne. Pour les besoins de la présente norme, les éléments de fixation pour structures en bois sont considérés comme étant des pointes, agrafes, vis, broches et boulons avec écrous. Ces éléments sont définis à l’article 3. La présente norme européenne spécifie également les procédures d'évaluation de conformité et inclut des exigences pour le marquage de ces produits.

La présente norme européenne ne couvre pas les éléments de fixation avec revêtement en résine ni les connecteurs traités avec des produits ignifuges pour améliorer leurs performances au feu. Elle ne couvre également pas les connecteurs avec revêtement en résine.

Lesene konstrukcije - Paličasta vezna sredstva - Zahteve

Ta evropski standard določa zahteve in preskusne metode za vidike materialov, geometrije, moči, trdote in vzdržljivosti (npr. zaščito pred korozijo) paličastih veznih sredstev, ki se uporabljajo za nosilne lesene strukture. Ta evropski standard velja samo za paličasta vezna sredstva, proizvedena iz jekla. Za namene tega standarda se za paličasta vezna sredstva štejejo žeblji, sponke, vijaki, centirni zatiči in sorniki z maticami. Definicije teh pojmov so podane v 3. točki. Ta evropski standard določa tudi ocenjevanje postopkov skladnosti in vključuje zahteve za označevanje teh izdelkov. Ta evropski standard ne pokriva veznih sredstev, obdelanih z zaščitnimi sredstvi proti ognju, ki izboljšujejo odpornost proti ognju. Ta evropski standard velja za vezna sredstva, ki so lahko prevlečena za naslednje namene: 1. zaščita pred korozijo (npr. vroče cinkanje, prevleke epoksi); 2. maziva (za lažje vstavljanje); 3. izboljšanje odstranitve in/ali kolacija (lepilna prevleka).

General Information

- Status

- Withdrawn

- Publication Date

- 22-May-2012

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 124 - Timber structures

- Drafting Committee

- CEN/TC 124/WG 4 - Connectors

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 27-Apr-2022

- Completion Date

- 14-Apr-2025

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 20-Jun-2012

Frequently Asked Questions

EN 14592:2008+A1:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Timber structures - Dowel-type fasteners - Requirements". This standard covers: This European Standard specifies the requirements and test methods for materials, geometry, strength, stiffness and durability ascpects (i.e. corrosion protection) of dowel-type fasteners for use in load bearing timber structures. Only dowel-type fasteners manufactured from steel are covered by this European Standard. For the purpose of this standard, dowel-type fasteners for timber structures are taken to be nails, staples, screws, dowels, and bolts with nuts. Definitions of these items are given in Clause 3. This European Standard specifies also the evaluation of conformity procedures and includes requirements for marking of these products. This European Standard does not cover resin coated dowel-type fasteners and fasterners treated with fire retardants to improve their fire performance. It also does not cover resin coated fasteners.

This European Standard specifies the requirements and test methods for materials, geometry, strength, stiffness and durability ascpects (i.e. corrosion protection) of dowel-type fasteners for use in load bearing timber structures. Only dowel-type fasteners manufactured from steel are covered by this European Standard. For the purpose of this standard, dowel-type fasteners for timber structures are taken to be nails, staples, screws, dowels, and bolts with nuts. Definitions of these items are given in Clause 3. This European Standard specifies also the evaluation of conformity procedures and includes requirements for marking of these products. This European Standard does not cover resin coated dowel-type fasteners and fasterners treated with fire retardants to improve their fire performance. It also does not cover resin coated fasteners.

EN 14592:2008+A1:2012 is classified under the following ICS (International Classification for Standards) categories: 21.060.01 - Fasteners in general; 91.080.20 - Timber structures. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14592:2008+A1:2012 has the following relationships with other standards: It is inter standard links to EN 14592:2008/FprA1, EN 14592:2008, EN 14592:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14592:2008+A1:2012 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/112. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 14592:2008+A1:2012 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

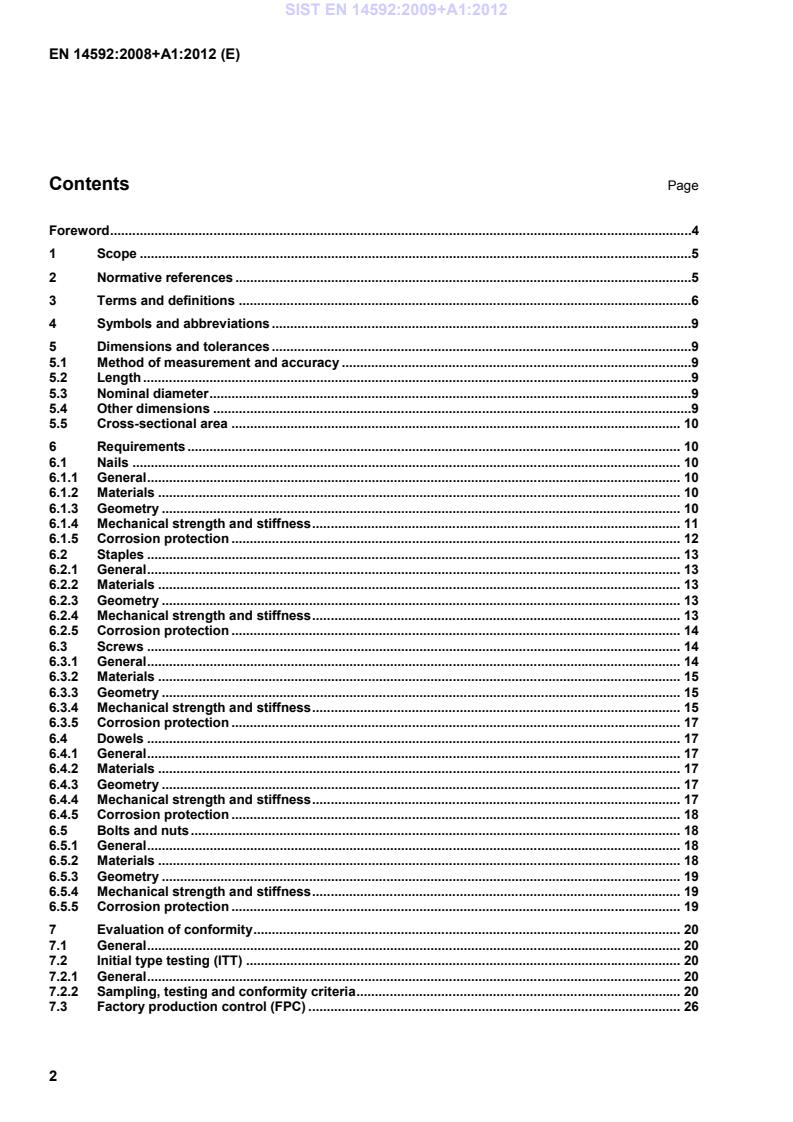

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Holzbauwerke - Stiftförmige Verbindungsmittel - AnforderungenStructures en bois - Eléments de fixation de type tige - ExigencesTimber structures - Dowel-type fasteners - Requirements91.080.20Lesene konstrukcijeTimber structures21.060.01Vezni elementi na splošnoFasteners in generalICS:Ta slovenski standard je istoveten z:EN 14592:2008+A1:2012SIST EN 14592:2009+A1:2012en,fr,de01-november-2012SIST EN 14592:2009+A1:2012SLOVENSKI

STANDARDSIST EN 14592:20091DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14592:2008+A1

May 2012 ICS 21.060.01; 91.080.20 Supersedes EN 14592:2008English Version

Timber structures - Dowel-type fasteners - Requirements

Structures en bois - Eléments de fixation de type tige - Exigences

Holzbauwerke - Stiftförmige Verbindungsmittel - Anforderungen This European Standard was approved by CEN on 9 August 2008 and includes Amendment 1 approved by CEN on 9 April 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14592:2008+A1:2012: ESIST EN 14592:2009+A1:2012

Expression of corrosion protection specifications . 35Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Contruction Products Directive . 37Bibliography . 44 SIST EN 14592:2009+A1:2012

EN 10025-2, Hot rolled products of structural steels - Part 2: Technical delivery conditions for non-alloy structural steels EN 10025-3, Hot rolled products of structural steels - Part 3: Technical delivery conditions for normalized/normalized rolled weldable fine grain structural steels EN 10083-1, Steels for quenching and tempering - Part 1: General technical delivery conditions EN 10083-2, Steels for quenching and tempering - Part 2: Technical delivery conditions for non alloy steels !EN 10088 (all parts), Stainless steels" EN 10149-1, Hot-rolled flat products made of high yield strength steels for cold forming – Part 1: General delivery conditions EN 10218-1, Steel wire and wire products - General - Part 1: Test methods SIST EN 14592:2009+A1:2012

(ISO 6892-1:2009)" EN ISO 9001, Quality management systems - Requirements (ISO 9001:2000) EN ISO 10666:1999, Drilling screws with tapping screw thread - Mechanical and functional properties (ISO 10666:1999) !deleted text" ISO 2081, Metallic coatings - Electroplated coatings of zinc on iron or steel 3 Terms and definitions For the purposes of this document, terms and definitions given in EN 1995-1-1:2004 and the following apply. 3.1 plain shank nail (smooth nail) nail that has a constant cross-section along its entire length (e.g. round, square or grooved nails) 3.2 threaded nail nail that has its shank profiled or deformed over a part of its length !lg as defined in Figure 1 b" 3.3 staple crown width distance between the outer edges of the staple legs SIST EN 14592:2009+A1:2012

a) Nominal diameter d and length l of nails (left) and screws (right). For screws the threaded length is shown, see also Figure 3 lg b) Length of the threaded part lg of threaded nails Figure 1 – Nominal diameter, length and length of the threaded part of nails and screws" !3.10 thread root diameter inner diameter of the thread of a screw NOTE The inner diameter is used in EN 1995-1-1 to determine the effective diameter for laterally loaded dowel type fasteners." 3.11 stiffness value based on required bend angle (deformation), αααα of the characteristic yield strength (capacity) either found by testing or calculated according to EN 1995-1-1 !3.12 coating type defines the purpose of a coating Coating type 1: Corrosion protection Coating type 2: Lubricant to facilitate insertion Coating type 3: Adhesive coating for improving withdrawal strength and/or for collation purposes" SIST EN 14592:2009+A1:2012

percentage elongation (%) Ah

nail head cross-sectional area (mm2) As

staple leg cross-sectional area (mm2) d

nominal diameter (mm) dh

head diameter (mm) !d1"

inner thread diameter; inner diameter of fluting (mm) def

effective screw diameter (mm) fax,k

characteristic withdrawal parameter (N/mm2) fhead,k

characteristic head pull-through parameter (N/mm2) ftens,k

characteristic tensile capacity (head pull-off or shank tensile capacity) (kN) ftor,k

characteristic torsional strength (Nmm) fu

tensile strength of the wire (N/mm2) ht

nail head thickness (mm) l

overall fastener length (mm) lg

length of profiling/threading (mm) lp

length of the nail point (mm) My,k

characteristic yield moment (Nmm) Rtor,k

characteristic torsional resistance to insertion into timber with a density of 450 kg/m3 when conditioned to constant mass at 20 ºC and 65 % relative humidity (Nmm) α

bend angle (o) ρk

characteristic timber density when conditioned to constant mass at 20 ºC and 65 % relative

humidity (kg/m3) 5 Dimensions and tolerances 5.1 Method of measurement and accuracy Dimensions shall be taken on the completed fastener using a calibrated device capable of achieving an accuracy of ± 1 % of the measurement. 5.2 Length Where appropriate the overall length of a fastener shall be measured and the result declared. When sampled in accordance with Tables 2 to 6 and measured, the overall length shall be within ± 2,5 % of the declared value. 5.3 Nominal diameter Where appropriate, the nominal diameter of a fastener shall be measured and the result declared. Unless otherwise stated in this standard, the nominal diameter shall be within ± 2,5 % of the declared value when sampled in accordance with Tables 2 to 6 and measured as follows: the diameter shall be measured at several points around the circumference and along the length; the !minimum" measurement shall be taken as the nominal diameter. 5.4 Other dimensions Where appropriate, other dimensions, e.g. point length of a fastener, threaded length and head thickness, shall be measured and the result declared. When sampled in accordance with Tables 2 to 6 and measured, these other dimensions shall be within ± 5 % of the declared values. SIST EN 14592:2009+A1:2012

EN 10016 (all parts), or wire drawn from austenitic stainless steel rods produced in accordance with

!EN 10088. The relevant specification shall be declared. Other steel grades may be used, provided it has been documented that the steel has at least equivalent mechanical properties to any of the grades listed in the above standards. All relevant information of the alternative steel grades shall be obtained from testing and declared as a part of the ITT." 6.1.3 Geometry The nominal diameter, d, of nail shall not be less than 1,9 mm and shall not be greater than 8,0 mm. The area of the nail head, Ah, shall not be less than 2,5 d2, and the thickness of the head, ht, shall not be less than 0,25 d (see Figure 2). The length (l) of the nail (see Figure 1) and the length of the point, lp, shall not be less than 0,5 d and shall not be greater than !2,5 d" (see Figure 2). For profiled nails the length of the the threated part shall be minimum 4,5 d. !If nails are coated with a type 3 coating, the coated length shall be at least 0,5 l." SIST EN 14592:2009+A1:2012

" Figure 2 – Geometry of nails heads and points !deleted text" 6.1.4 Mechanical strength and stiffness 6.1.4.1 General For the purpose of the mechanical strength of nails the following characteristic properties shall be used in this standard: characteristic yield moment, characteristic withdrawal parameter, characteristic head pull-through parameter, characteristic tensile capacity. The characteristic strength results for nails (see 6.1.4.2 to 6.1.4.5) shall be declared either directly from tests or, in certain cases and types of nails, from equations given in EN 1995-1-1. Where characteristic strength values are declared from test results, they shall be calculated in accordance with EN 14358. For the purposes of strength calculations for nailed joints, the nail diameter shall be taken as the nominal diameter, d, measured in accordance with 5.3. For the purpose of the mechanical stiffness of nails the following characteristic properties shall be used in this standard: characteristic yield moment. For the purposes of stiffness (bend angle α), for round or square cross-section nails, the declaration is related to the result of the characteristic yield moment My,k which shall be declared either directly by testing in accordance with EN 409 or calculated from the relevant equations given in EN 1995-1-1. For all other types of nail the result shall be declared by testing in accordance with EN 409. SIST EN 14592:2009+A1:2012

the result shall be declared on one or more characteristic timber densities or on other types of wood based products, either directly by testing in accordance with EN 1383 or declared by calculation according to the relevant equations given in EN 1995-1-1.

For all other types of nail, the characteristic head pull-through parameter fhead,k

the result shall be declared on one or more characteristic timber densities or on other types of wood based products, by testing in accordance with EN 1383. 6.1.4.5 Characteristic tensile capacity The characteristic tensile capacity of nails ftens,k (head pull-off or shank tensile capacity) the result shall be declared by testing in accordance with EN 1383, using a steel plate to replace the head side timber member shown in Figure 4 of that standard. The steel plate shall be of sufficient thickness to induce either a pull-off failure of the head, or a tensile failure of the shank and shall contain a pre-drilled hole for the nail which shall not exceed the maximum outer diameter of the nail + 1 mm in diameter. For partially profiled nails the area of transition from the profiled to the smooth part of the shank shall be located within the free length of testing and shall have a clear distance from the jaws of the testing equipment of at least 3 d. The rate of loading shall be chosen so that the failure load (ultimate load) is reached within 10 s ± 5 s. 6.1.5 Corrosion protection !For nails, where corrosion protection is required, the grade of the parent material or thickness of coating shall be declared. NOTE Examples of corrosion protection or material specifications are given in

EN 1995-1-1 and Annex A." SIST EN 14592:2009+A1:2012

EN 1995-1-1. 6.2.4.3 Characteristic withdrawal parameter For staples the characteristic withdrawal parameter fax,k the result shall be declared on one or more characteristic timber densities or on other types of wood based products, either directly by testing in accordance with EN 1382 or declared by calculation according to the relevant equations given in EN 1995-1-1. 6.2.4.4 Characteristic head pull-through parameter For staples the characteristic head pull-through parameter fhead,k the result shall be declared on one or more characteristic timber densities or on other types of wood based products, by testing in accordance with

EN 1383. 6.2.5 Corrosion protection !For staples, where corrosion protection is required, the grade of the parent material or thickness of coating shall be declared. NOTE Examples of corrosion protection or material specifications are given in

EN 1995-1-1 and Annex A." 6.3 Screws 6.3.1 General Screws for structural timber applications shall either have their threaded part turned down from the original rod diameter, and therefore have a smooth shank diameter equal to the maximum outer cross-sectional diameter of the threaded part, or screws shall be produced by rolling or forging the wire rod, the shank diameter for these screws shall be a thinner smooth shank diameter compared to the maximum outer cross-sectional thread diameter. The threads shall be clean and sharply cut or formed. Screws of many different forms shall be available for wood construction, and these shall be suitable for use provided the minimum requirements given in 6.3.2 to 6.3.5 are fulfilled. SIST EN 14592:2009+A1:2012

2,4 mm and not greater than 24 mm. The nominal diameter shall be declared. The inner threaded diameter of screws, d1, shall not be less than 60 % and not more than 90 % of the outer threaded diameter, d, (i.e. 0,6 d ≤ d1 ≤ 0,9 d, see Figure 3). Screws shall be threaded over !a minimum length lg of 4 d (i.e. lg ≥ 4 d, see Figure 3)". The length (l) and the threaded length (lg) shall be declared. !The head diameter (dh) shall be declared."

Figure 3 – Geometry of screws

6.3.4 Mechanical strength and stiffness 6.3.4.1 General For the purpose of the mechanical strength of screws the following characteristic properties shall be used in this standard: characteristic yield moment, characteristic withdrawal parameter, characteristic head pull-through parameter, characteristic tensile capacity, characteristic torsional ratio. SIST EN 14592:2009+A1:2012

For screws the characteristic withdrawal parameter fax,k the result shall be declared on one or more characteristic timber densities or on other types of timber products, either directly by testing in accordance with EN 1382 or declared by calculation according to the relevant equations given in EN 1995-1-1. 6.3.4.4 Characteristic head pull-through parameter For screws the characteristic head pull-through parameter fhead,k the result shall be declared by testing in accordance with EN 1383 on one or more characteristic timber densities or on other types of wood based products. NOTE Combining the screw with a washer, where appropriate, may enhance the head pull-through parameter. 6.3.4.5 Characteristic tensile capacity For screws the characteristic tensile capacity ftens,k (head pull-off or shank tensile capacity) the result shall be declared by testing in accordance with EN 1383:1999, using a steel plate to replace the head side timber member shown in Figure 4 of that standard. The steel plate shall be of sufficient thickness to induce either a pull-off failure of the head, or a tensile failure of the shank and shall contain a pre-drilled hole for the screw which may not exceed the maximum outer diameter of the screw + 1 mm in diameter. For partially profiled screws the area of transition from the profiled to the smooth part of the shank shall be located within the free length of testing and shall have a clear distance from the jaws of the testing equipment of at least 3 d1. The rate of loading shall be chosen so that the failure load (ultimate load) is reached within 10 s ± 5 s. 6.3.4.6 Characteristic torsional ratio For screws the characteristic torsional strength ftor,k shall be determined by testing in accordance with the method given in EN ISO 10666:1999, 4.2.3, and the torsional resistance to insertion into timber, Rtor,k,

shall be determined in accordance with the method given in Annex B of this standard. The ratio ftor,k / Rtor,k ≥

1,5 shall be maintained for screws used in load-bearing timber structures. SIST EN 14592:2009+A1:2012

EN 1995-1-1 and Annex A." 6.4 Dowels 6.4.1 General Dowels shall have a circular, deformed circular or rectangular cross-section. 6.4.2 Materials !Dowels shall be produced from steel rods either to EN 10025-2, EN 10025-3, EN 10149-1 or EN 10277-2, or from stainless steel rods to EN 10088-3. The minimum specification for steel dowels shall be S235 to

EN 10025-2 or EN 10277-2. The minimum specification for stainless steel dowels shall be 1.4401 to

EN 10088-3. The minimum percentage elongation (A5) measured according to EN ISO 6892-1 shall be 8 %. The relevant specification shall be declared. Other steel grades may be used, provided it has been documented that the steel has at least equivalent mechanical properties to any of the permitted grades listed in the above standards. All relevant information of the alternative steel grades shall be obtained from testing and declared as a part of the ITT." 6.4.3 Geometry !Dowels shall have a constant prismatic shape with circular or fluted shank, and have a minimum diameter of 6 mm, and a maximum diameter of 30 mm. Where the cross-section is fluted, the inside diameter di shall not be less than 95 % of the outside diameter. The tolerance on the diameter of dowels with a constant circular cross-section shall be within -0,1/+0,5 mm measured on the finished dowel with corrosion protection if any. The nominal diameter and length of a dowel shall be declared." 6.4.4 Mechanical strength and stiffness 6.4.4.1 General For the purpose of the mechanical strength of dowels the following characteristic properties shall be used in this standard: characteristic yield moment. The characteristic strength results for dowels (see 6.4.4.2) shall be declared either directly from tests or, in the case of certain strength properties and types of dowels, from equations given in EN 1995-1-1. Where characteristic strength values are declared from test results, they shall be calculated in accordance with

EN 14358. For the purposes of stiffness (bend angle α), the declaration is related to the result of the characteristic yield moment My,k which shall be declared either directly by testing in accordance with EN 409 or calculated from the relevant equations given in EN 1995-1-1. SIST EN 14592:2009+A1:2012

EN 1995-1-1 and Annex A." 6.5 Bolts and nuts 6.5.1 General The threated part of bolts and nuts shall have a circular cross-section. 6.5.2 Materials Materials for bolts and nuts shall be declared to the specifications given in Table 1. SIST EN 14592:2009+A1:2012

Table 1 – Material specifications for bolts and nuts Bolts Nuts Grade Standard Grade Standard 4.6 EN ISO 4016 4

d > M16 EN ISO 4034 4.8 EN ISO 4018 5

d ≤ M16 5.6 EN ISO 4014 EN ISO 4017 5 8.8 EN ISO 4014 EN ISO 4017 8 EN ISO 4032 EN ISO 780 6.5.3 Geometry Bolts shall either have heads and nuts of hexagonal shape or, if the heads and nuts are not hexagonal, shall have equivalent performance to a bolt of the same size with a hexagonal head and nut. Bolts shall have a minimum diameter of 6 mm and a maximum diameter of 30 mm. The nominal diameter and length of the bolt shall be declared. 6.5.4 Mechanical strength and stiffness 6.5.4.1 General For the purpose of the mechanical strength of bolts the following characteristic properties shall be used in this standard: characteristic yield moment. The characteristic strength results (see 6.5.4.2) shall be declared either directly from tests or, in the case of certain strength properties and types of bolts, from equations given in EN 1995-1-1. Where characteristic strength values are declared from test results, they shall be calculated in accordance with EN 14358. For the purposes of stiffness (bend angle α), the declaration is related to the result of the characteristic yield moment My,k which shall be declared either directly by testing in accordance with EN 409 or calculated from the relevant equations given in EN 1995-1-1. 6.5.4.2 Characteristic yield moment The characteristic yield moment of steel bolts My,k shall be declared and the result shall either be found by testing in accordance with EN 409, where the bend angle, α, is limited to 45/d 0,7 degrees (where d is in mm), or calculated from the relevant equations given in EN 1995-1-1. 6.5.5 Corrosion protection !For bolts and nuts, where corro

...

기사 제목: EN 14592:2008+A1:2012 - 목구조물 - 다우타입 결합부재 - 요구사항 기사 내용: 이 유럽표준은 하중을 지탱하는 목구조물에 사용되는 다우타입 결합부재의 재료, 형상, 강도, 강성 및 내구성(부식 방지) 요건과 시험 방법을 규정합니다. 이 유럽표준은 스틸로 만들어진 다우타입 결합부재에만 적용됩니다. 이 표준에서 목구조물을 위한 다우타입 결합부재는 못, 스테이플, 나사, 다오, 너트와 볼트 등을 포함하며, 이들의 정의는 3조에 제시되었습니다. 이 유럽표준은 또한 준수성 평가 절차와 해당 제품에 대한 마킹 요건도 규정합니다. 그러나, 이 유럽표준은 수지 코팅된 다우타입 결합부재 및 방화성 향상을 위해 방화제 처리된 부재에는 해당하지 않습니다. 또한, 수지 코팅된 부재에도 해당하지 않습니다.

The article discusses the standard EN 14592:2008+A1:2012, which relates to dowel-type fasteners used in timber structures. The standard specifies requirements and test methods for the materials, geometry, strength, stiffness, and durability, including corrosion protection. It only applies to dowel-type fasteners made of steel. The standard includes nails, staples, screws, dowels, and bolts with nuts within its definition of dowel-type fasteners. It also covers evaluation of conformity procedures and requirements for product marking. However, the standard does not apply to resin coated dowel-type fasteners, fasteners treated with fire retardants to enhance fire performance, or resin coated fasteners.

기사 제목: EN 14592:2008+A1:2012 - 목재 구조물 - 다우리 형식 고정장치 - 요구사항 기사 내용: 이 유럽 표준은 하중을 지탱하는 목재 구조물에 사용되는 다우리 형식 고정장치의 재료, 기하학적 특성, 강도, 강성 및 내구성(부식 방지 포함)에 대한 요구 사항과 시험 방법을 규정합니다. 이 유럽 표준은 강으로 제조된 다우리 형식 고정장치만 다룹니다. 이 표준에서는 목재 구조물용 다우리 형식 고정장치를 못, 스테이플, 나사, 다우리, 너트와 볼트로 정의합니다. 이러한 항목들에 대한 정의는 3조에서 제공됩니다. 이 유럽 표준은 준수 평가 절차와 해당 제품의 마킹 요구 사항도 규정합니다. 이 유럽 표준은 수지 코팅된 다우리 형식 고정장치와 화재 저항성 향상을 위해 화재 방지제로 처리된 고정장치를 포함하지 않습니다. 또한 수지 코팅된 고정장치도 포함하지 않습니다.

記事のタイトル:EN 14592:2008+A1:2012 - 木材構造物 - ダウエル型留め具 - 要件 記事の内容:この欧州標準は、荷重を支える木材構造物に使用されるダウエル型留め具の材料、形状、強度、剛性、耐久性(腐食防止など)の要件と試験方法を規定しています。 この欧州標準は、鋼材で作られたダウエル型留め具にのみ適用されます。この規格では、木材構造物用のダウエル型留め具として、釘、ステープル、ビス、ダウエル、ナットとボルトなどが含まれます。これらのアイテムの定義は第3条で与えられています。この欧州標準では、適合性評価手続きおよびこれらの製品のマーキング要件も規定しています。 ただし、この欧州標準は、樹脂コーティングされたダウエル型留め具や難燃剤処理された留め具(防火性能を向上させるため)は対象外です。また、樹脂コーティングされた留め具にも対象外です。

記事タイトル:EN 14592:2008+A1:2012 - 木材構造物-ダウェルタイプの固定具-要件 記事内容:このヨーロッパ規格は、荷重を支えるために使用される木材構造物のダウェルタイプの固定具の材料、形状、強度、剛性、耐久性(腐食防止を含む)に関する要件と試験方法を定めています。このヨーロッパ規格は、鋼製のダウェルタイプの固定具のみを対象としています。この規格では、釘、ステープル、ネジ、ダウェル、ナットとボルトをダウェルタイプの固定具の定義に含めています。これらのアイテムの定義は、第3節で提供されています。このヨーロッパ規格は、準拠評価手続きとこれらの製品のマーキング要件も含みます。 このヨーロッパ規格は、樹脂コーティングされたダウェルタイプの固定具や防火性能を向上させるために防火剤で処理された固定具は対象外です。また、樹脂コーティングされた固定具も対象外です。

The article discusses the requirements and test methods for dowel-type fasteners used in load bearing timber structures. The standard applies only to fasteners made of steel, such as nails, staples, screws, dowels, and bolts with nuts. It outlines the specifications for materials, geometry, strength, stiffness, and durability, including corrosion protection. The standard also includes procedures for evaluating conformity and requirements for product marking. However, it does not cover resin coated fasteners, fasteners treated with fire retardants, or resin coated dowel-type fasteners.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...