ISO/TS 16949:1999

(Main)Quality systems — Automotive suppliers — Particular requirements for the application of ISO 9001:1994

Quality systems — Automotive suppliers — Particular requirements for the application of ISO 9001:1994

Systèmes qualité — Fournisseurs pour l'automobile — Exigences particulières pour l'application de l'ISO 9001:1994

General Information

Relations

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 16949

First edition

1999-03-01

Quality systems — Automotive suppliers —

Particular requirements for the application

of ISO 9001:1994

Systèmes qualité — Fournisseurs de l'automobile — Exigences

particulières pour l'application de l'ISO 9001:1994

A

Reference number

ISO/TS 16949:1999(E)

---------------------- Page: 1 ----------------------

ISO/TS 16949:1999(E)

© ISO 1999

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or

utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm,

without permission in writing from the publisher.

International Organization for Standardization

Case postale 56 • CH-1211 Genève 20 • Switzerland

Internet iso@iso.ch

Printed in Switzerland

The content inside the boxed text of this document is ISO 9001:1994 text and is protected by the above

copyright statement. The text outside the boxes has been originated by the International Automotive

Task Force. Copyright for this text is held by ANFIA, CCFA/FIEV, VDA (see below) and the car

manufacturers DaimlerChrysler Corp., Ford Motor, General Motors.

Neither this ISO document nor any extract from it may be reproduced in a retrieval system or transmitted

in any form or by any means, electronic, photocopying, recording or otherwise without prior written

permission being secured.

Requests for permission to reproduce non-ISO text should be addressed to one of the addresses below.

Automotive Industry Action Group (AIAG)

26200 Lahser Road, Suite 200 Southfield, Michigan 48034 USA

tel. +1 (248) 358-35 70 fax: +1 (248) 358-3253 e-mail: bbaker@aiag.org

Associazione Nazionale Fra Industrie Automobilistiche (ANFIA/Italy)

Comité des Constructeurs Français d'Automobiles (CCFA/France)

Fédération des Industries des Équipements pour Véhicules (FIEV/France)

Verband der Automobilindustrie (VDA/Germany)

Qualitätsmanagement Center (QMC)

ii

---------------------- Page: 2 ----------------------

ISO/TS 16949:1999(E)

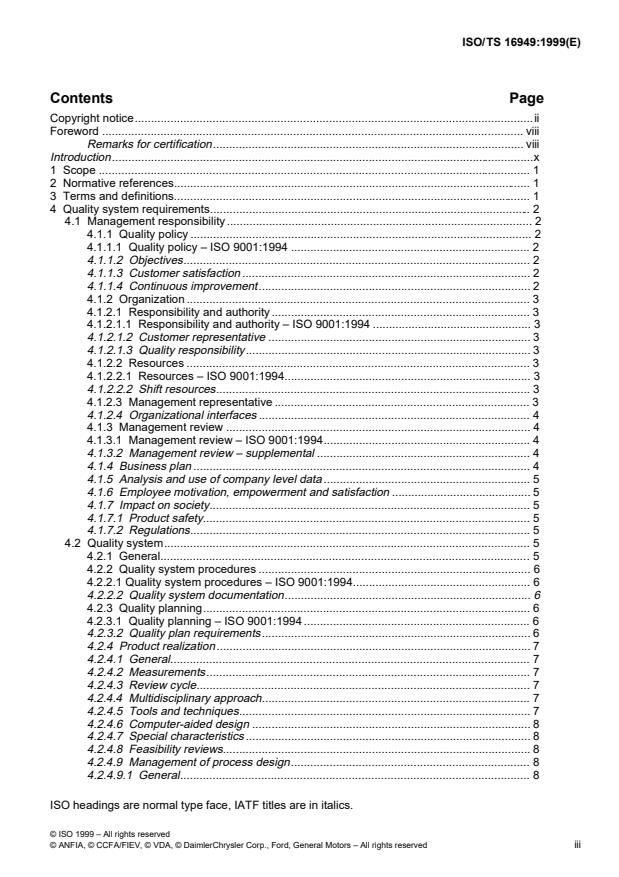

Contents Page

Copyright notice.ii

Foreword . viii

Remarks for certification. viii

Introduction.x

1 Scope . 1

2 Normative references. 1

3 Terms and definitions. 1

4 Quality system requirements. 2

4.1 Management responsibility. 2

4.1.1 Quality policy . 2

4.1.1.1 Quality policy – ISO 9001:1994 . 2

4.1.1.2 Objectives. 2

4.1.1.3 Customer satisfaction . 2

4.1.1.4 Continuous improvement. 2

4.1.2 Organization . 3

4.1.2.1 Responsibility and authority . 3

4.1.2.1.1 Responsibility and authority – ISO 9001:1994 . 3

4.1.2.1.2 Customer representative . 3

4.1.2.1.3 Quality responsibility. 3

4.1.2.2 Resources . 3

4.1.2.2.1 Resources – ISO 9001:1994. 3

4.1.2.2.2 Shift resources. 3

4.1.2.3 Management representative . 3

4.1.2.4 Organizational interfaces . 4

4.1.3 Management review . 4

4.1.3.1 Management review – ISO 9001:1994. 4

4.1.3.2 Management review – supplemental . 4

4.1.4 Business plan . 4

4.1.5 Analysis and use of company level data . 5

4.1.6 Employee motivation, empowerment and satisfaction . 5

4.1.7 Impact on society. 5

4.1.7.1 Product safety. 5

4.1.7.2 Regulations. 5

4.2 Quality system. 5

4.2.1 General.5

4.2.2 Quality system procedures . 6

4.2.2.1 Quality system procedures – ISO 9001:1994. 6

4.2.2.2 Quality system documentation. 6

4.2.3 Quality planning. 6

4.2.3.1 Quality planning – ISO 9001:1994 . 6

4.2.3.2 Quality plan requirements. 6

4.2.4 Product realization. 7

4.2.4.1 General. 7

4.2.4.2 Measurements. 7

4.2.4.3 Review cycle. 7

4.2.4.4 Multidisciplinary approach. 7

4.2.4.5 Tools and techniques. 7

4.2.4.6 Computer-aided design . 8

4.2.4.7 Special characteristics . 8

4.2.4.8 Feasibility reviews. 8

4.2.4.9 Management of process design. 8

4.2.4.9.1 General. 8

ISO headings are normal type face, IATF titles are in italics.

© ISO 1999 – All rights reserved

© ANFIA, © CCFA/FIEV, © VDA, © DaimlerChrysler Corp., Ford, General Motors – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TS 16949:1999(E)

Contents Page

4.2.4.9.2 Process design input .8

4.2.4.9.3 Process design output.8

4.2.4.9.4 Process verification .9

4.2.4.10 Control plan.9

4.2.4.11 Product approval process.9

4.2.5 Plant, facility and equipment planning .9

4.2.6 Tooling management.10

4.2.7 Process improvement.10

4.2.8 Quality system performance.10

4.3 Contract review .10

4.3.1 General .10

4.3.2 Review .11

4.3.2.1 Review – ISO 9001:1994.11

4.3.2.2 Review – supplemental .11

4.3.3 Amendment to a contract .11

4.3.4 Records.11

4.4 Design control.11

4.4.1 General .11

4.4.2 Design and development planning .11

4.4.2.1 Design and development planning – ISO 9001:1994.11

4.4.2.2 Required skills.12

4.4.2.3 Research and development.12

4.4.3 Organizational and technical interfaces.12

4.4.4 Design input .12

4.4.4.1 Design input – ISO 9001:1994 .12

4.4.4.2 Reliability objectives . 12

4.4.4.3 Use of information .12

4.4.5 Design output.13

4.4.5.1 Design output – ISO 9001:1994 .13

4.4.5.2 Design optimization .13

4.4.6 Design review.13

4.4.7 Design verification.13

4.4.8 Design validation.14

4.4.8.1 Design validation – ISO 9001:1994 .14

4.4.8.2 Design validation – supplemental .14

4.4.8.3 Prototype programme.14

4.4.9 Design changes .14

4.4.9.1 Design changes – ISO 9001:1994.14

4.4.9.2 Evaluation of design change .14

4.5 Document and data control .14

4.5.1 General .14

4.5.2 Document and data approval and issue .15

4.5.2.1 Document and data approval and issue – ISO 9001:1994.15

4.5.2.2 Engineering specifications.15

4.5.3 Document and data changes.15

4.6 Purchasing.16

4.6.1 General .16

4.6.1.1 General – ISO 9001:1994 .16

4.6.1.2 Customer-approved subcontractors .16

4.6.1.3 Regulatory compliance.16

4.6.2 Evaluation of subcontractors .16

4.6.2.1 Evaluation of subcontractors – ISO 9001:1994 .16

ISO headings are normal type face, IATF titles are in italics.

© ISO 1999 – All rights reserved

iv © ANFIA, © CCFA/FIEV, © VDA, © DaimlerChrysler Corp., Ford, General Motors – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TS 16949:1999(E)

Contents Page

4.6.2.2 Subcontractor development. 16

4.6.2.3 Scheduling subcontractors. 17

4.6.3 Purchasing data. 17

4.6.4 Verification of purchased product . 17

4.6.4.1 Supplier verification at subcontractor's premises . 17

4.6.4.2 Customer verification of subcontracted product. 17

4.7 Control of customer-supplied product . 17

4.7.1 Control of customer-supplied product – ISO 9001:1994 . 17

4.7.2 Customer owned tooling. 18

4.8 Product identification and traceability . 18

4.9 Process control. 18

4.9.1 General. 18

4.9.1.1 General – ISO 9001:1994. 18

4.9.1.2 Cleanliness of premises. 19

4.9.1.3 Contingency plans . 19

4.9.1.4 Designation of special characteristics . 19

4.9.1.5 Preventive maintenance . 19

4.9.2 Job instructions. 19

4.9.3 Maintaining process control . 20

4.9.4 Verification of job set-ups . 20

4.9.5 Appearance items. 20

4.10 Inspection and testing . 21

4.10.1 General. 21

4.10.1.1 General – ISO 9001:1994. 21

4.10.1.2 Acceptance criteria . 21

4.10.2 Receiving inspection and testing . 21

4.10.2.4 Incoming product quality. 21

4.10.3 In-process inspection and testing . 21

4.10.4 Final inspection and testing . 22

4.10.4.1 Final inspection and testing – ISO 9001:1994. 22

4.10.4.2 Layout inspection and functional testing . 22

4.10.5 Inspection and test records. 22

4.10.6 Laboratory requirements. 22

4.11 Control of inspection, measuring and test equipment. 22

4.11.1 General. 22

4.11.1.1 General – ISO 9001:1994. 22

4.11.1.2 Measurement system analysis. 23

4.11.2 Control procedure. 23

4.11.3 Records . 24

4.12 Inspection and test status. 24

4.13 Control of nonconforming product . 24

4.13.1 General. 24

4.13.1.1 General – ISO 9001:1994. 24

4.13.1.2 Suspect material or product. 24

4.13.1.3 Corrective action plan . 24

4.13.2 Review and disposition of nonconforming product. 25

4.13.3 Control of reworked product . 25

4.13.4 Engineering approved authorization. 25

4.14 Corrective and preventive action . 25

4.14.1 General. 25

4.14.1.1 General – ISO 9001:1994. 25

4.14.1.2 Problem solving . 25

ISO headings are normal type face, IATF titles are in italics.

© ISO 1999 – All rights reserved

© ANFIA, © CCFA/FIEV, © VDA, © DaimlerChrysler Corp., Ford, General Motors – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/TS 16949:1999(E)

Contents Page

4.14.1.3 Mistake-proofing.26

4.14.2 Corrective action .26

4.14.2.1 Corrective action – ISO 9001:1994.26

4.14.2.2 Corrective action impact.26

4.14.2.3 Returned product test/analysis .26

4.14.3 Preventive action.26

4.15 Handling, storage, packaging, preservation and delivery .27

4.15.1 General .27

4.15.2 Handling.27

4.15.3 Storage .27

4.15.3.1 Storage – ISO 9001:1994.27

4.15.3.2 Inventory .27

4.15.4 Packaging .27

4.15.4.1 Packaging – ISO 9001:1994.27

4.15.4.2 Customer packaging standards.27

4.15.4.3 Labelling.27

4.15.5 Preservation .27

4.15.6 Delivery .27

4.15.6.1 Delivery – ISO 9001:1994 .27

4.15.6.2 Performance monitoring of supplier delivery.28

4.15.6.3 Production scheduling .28

4.15.6.4 Electronic communication.28

4.15.6.5 Shipment notification system.28

4.16 Control of quality records .28

4.16.1 Control of quality records – ISO 9001:1994.28

4.16.2 Record retention.29

4.17 Internal quality audits .29

4.17.1 Internal quality audits – ISO 9001:1994.29

4.17.2 Internal quality audits – supplemental .29

4.17.2.1 General .29

4.17.2.2 System audit .29

4.17.2.3 Process audit .29

4.17.2.4 Product audit .29

4.17.3 Auditor qualification .30

4.18 Training.30

4.18.1 Training – ISO 9001:1994 .30

4.18.2 Training effectiveness .30

4.18.3 Training on the job.30

4.19 Servicing .30

4.19.1 Servicing – ISO 9001:1994.30

4.19.2 Feedback of information from service.30

4.19.3 Servicing agreement with customer.30

4.20 Statistical techniques .31

4.20.1 Identification of need .31

4.20.2 Procedures.31

4.20.3 Identification of statistical tools .31

4.20.4 Knowledge of basic statistical concepts .31

Annex A (normative) Terms and definitions.32

Annex B (normative) Control plan.39

Annex C (informative) Special characteristics.40

Bibliography.41

ISO headings are normal type face, IATF titles are in italics.

© ISO 1999 – All rights reserved

vi © ANFIA, © CCFA/FIEV, © VDA, © DaimlerChrysler Corp., Ford, General Motors – All rights reserved

---------------------- Page: 6 ----------------------

ISO/TS 16949:1999(E)

Contents Page

International Standards . 41

Internationally agreed manuals . 41

Common customer manuals. 41

AIAG. 41

ANFIA. 41

FIEV and French car manufacturers. 42

VDA. 42

ISO headings are normal type face, IATF titles are in italics.

© ISO 1999 – All rights reserved

© ANFIA, © CCFA/FIEV, © VDA, © DaimlerChrysler Corp., Ford, General Motors – All rights reserved vii

---------------------- Page: 7 ----------------------

ISO/TS 16949:1999(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.