ISO 10721-1:1997

(Main)Steel structures — Part 1: Materials and design

Steel structures — Part 1: Materials and design

Establishes the principles and general rules for the use of steel materials and design of steel structures in buildings. It is also applicable to bridges, civil engineering and related structures, but for such structures it may be necessary to consider other requirements.

Structures en acier — Partie 1: Matériaux et conception

General Information

Standards Content (Sample)

INTERNATIONAL IS0

STANDARD 10721-I

First edition

1997-02-01

Steel structures -

Part 1:

Materials and design

Structures en acier -

Partie 1: Matgriaux et conception

Reference number

IS0 10721-1:1997(E)

ISOlO721-1:1997(E)

Page

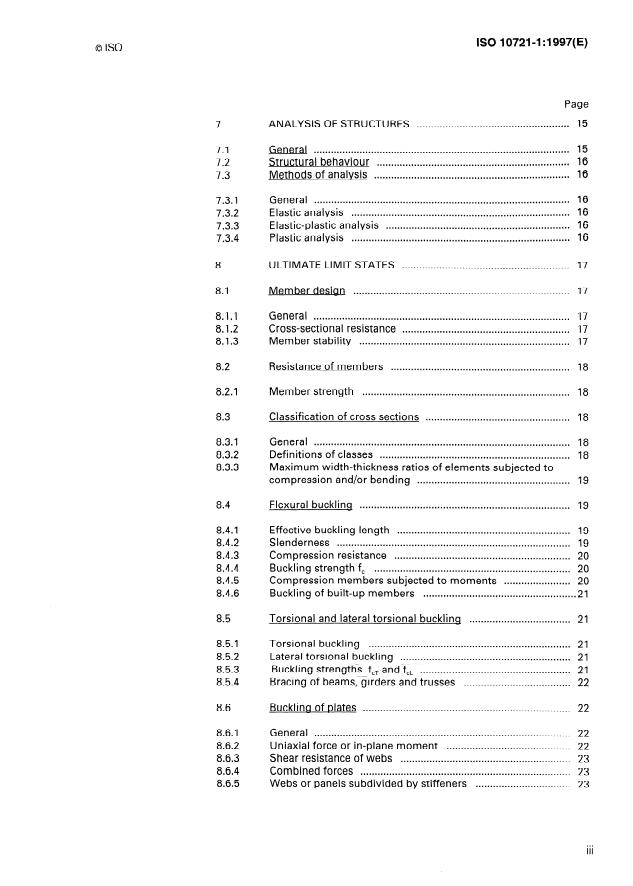

CONTENTS

1 SCOPE .

.......................................................... 1

2 NORMATIVE REFERENCES

..................................................... 2

3 DEFINITIONS AND SYMBOLS

3.1 Definitions .

3.2 List of svmbols . 5

4 DOCUMENTATION OF THE DESIGN . 11

................................................................................. 11

4.1 Calculations

......................................................................................... 11

4.2 Testing

............................................................................ 11

4.3 Documentation

....................................................... 11

5 BASIC DESIGN PRINCIPLES

............................... 11

5.1 Obiectives and general recommendations

5.2 Limit states .

............................... 12

5.3 Design situations and member resistance

5.3.1 General .

5.3.2 Design situations . 12

5.3.3 Member resistance . 13

...................................................................... 13

6 BASIC VARIABLES

61 General .

6:2 Actions .

6.2.1 General . 13

6.2.2 . 14

Design value

...................................................................................... 14

6.3 Materials

6.3.1 General .

6.3.2 Structural steels .

6.3.3 Connecting devices .

6.3.4 . 15

Testing and inspection of materials

............................................................. 15

64 Geometrical parameters

......................................................... 15

6:5 Desiqn value of resistance

0 IS0 1997

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or

utilized in any form or by any means, electronic or mechanical, including photocopying and

microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case postale 56 l CH-1211 Geneve 20 l Switzerland

Internet central @ iso.ch

x.400 c=ch; a=400net; p=iso; o=isocs; s=central

Printed in Switzerland

ii

IS0 10721=1:1997(E)

0 IS0

Page

ANALYSIS OF STRUCTURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-

General .

7.1

Structural behaviour .

7.2

Methods of analysis .

7.3

General .

7.3.1

Elastic analysis .

7.3.2

Elastic-plastic analysis .

7.3.3

............................................................................

7.3.4 Plastic analysis

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8 ULTIMATE LIMIT STATES

. . . . .*.*.* 17

8.1 Member desion

8.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.1.2 Cross-sectional resistance

. . . . . . . . . . . . . . . . .‘. 17

8.1.3 Member stability

8.2 Resistance of members . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 Member strength . . . . . . . . . . . . . . . . . . . . . .~.~.~.

Classification of cross sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.3

General .‘.,. 18

8.3.1

Definitions of classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .~.~. 18

8.3.2

Maximum width-thickness ratios of elements subjected to

8.3.3

compression and/or bending . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .*. 19

8.4 Flexural buckling

............................................................ 19

8.4.1 Effective buckling length

................................................................................. 19

8.4.2 Slenderness

............................................................. 20

8.4.3 Compression resistance

.................................................................... 20

8.4.4 Buckling strength f,

....................... 20

8.4.5 Compression members subjected to moments

Buckling of built-up members . 21

8.4.6

Torsional and lateral torsional bucklinq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

85 .

Torsional buckling . 21

8.5.1

Lateral torsional buckling . 21

8.5.2

Buckling strength< f,, and fcL . 21

8.5.3

..................................... 22

8.5.4 Bracing of beams, girders and trusses

8.6 Buckling of plates . . . . . . . . .‘. 22

General . .‘.,. 22

8.6.1

Uniaxial force or in-plane moment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.6.2

Shear resistance of webs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .~. 23

8.6.3

Combined forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.6.4

. . . . . . . . . . . . . . .a.

8.6.5 Webs or panels subdivided by stiffeners 23

IS0 10721=1:1997(E)

0 IS0

Page

8.7

Connections, general requirements

. . . . . . .‘.

88 .

Bolted connections . . . . . . . . . . . . . . . . . . .~.~.

8.8.1

General .

8.8.2

Bolting details .

8.8.3

Strength of connections with bolts and rivets

.........................

8.8.4

Slip coefficients .

8.8.5

Deduction for holes

....................................................................

8.8.6

Length of connection

....................................................................

,.,.*.,.,.

Welded connections

8.9

Scope .

8.9.1

.................................................................

8.9.2 General requirements

............................................................................

8.9.3 Types of welds

...................................................................

8.9.4 Design assumptions

.......................................................................

8.9.5 Design provisions

8.9.6 Complete joint penetration groove welds in butt

...............................................................................

and tee joints

...................................................................................

8.9.7 Fillet welds

.....................................................................

8.9.8 Plug and slot welds

. . . . . . . . . . . . . .~.‘

8.10 Joints in contact bearing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 SERVICEABILITY LIMIT STATES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 FATIGUE

10.1 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .~.

10.1 .I General .

...................................................................................

10.1.2 Limitations

........... 35

10.1.3 Situations in which no fatigue assessment is required

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fatigue assessment procedures

10.2

............... 36

10.2.1 Fatigue assessment based on nominal stress range

........ 37

10.2.2 Fatigue assessment based on a geometric stress range

............................................................................

10.3 Fatioue loading

.................................................................

10.4 Fatigue stress spectra

........................................................................

10.4.1 Stress calculation

...................................................

10.4.2 Design stress range spectrum

.~.,.~.,.

10.5 Fatigue strength

10.5.1 Definition of fatigue strength curves for classified structural

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

details

10.5.2 Definition of reference fatigue strength curves for

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

non-classified details

.~.,.,.,.

10.6 Fatioue strength modifications

Partial safety factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .‘.

10.7

IV

0 IS0

ISO10721-1:1997(E)

Page

...................................

10.7.1 Partial safety factors for fatigue loading

.................................

10.7.2 Partial safety factors for fatigue strength

............................................

10.7.3 Values of the partial safety factors

.............................................................................................................

Annex A

BASIC VARIABLES .

A.6

.......................................................................................

A.6.3 Materials

A.6.3.2 Structural steel .

...................................................... 41

A7 . ANALYSIS OF STRUCTURES

A.7.1 General .

A.7.2 Structural behaviour .

A.7.3 Methods of analysis .

A.7.3.2 Elastic analysis .

Plastic analysis .

A.7.3.4

ULTIMATE LIMIT STATE .

A.8

Resistance of structural members .

A.8.2

Classification of cross sections .

A.8.3

..........................................................................................

A.8.3.1 General

...................................................................

A.8.3.2 Definitions of classes

Maximum width-thickness ratios of elements subjected to

A.8.3.3

...................................................... 46

compression and/or bending

............................................................................ 48

A.8.4 Flexural buckling

Effective length .

A.8.4.1

Slenderness .

A.8.4.2

Compression resistance .

A.8.4.3

Determination off, .

A.8.4.4

Compression mem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.