IEC 60077-1:2017

(Main)Railway applications - Electric equipment for rolling stock - Part 1: General service conditions and general rules

Railway applications - Electric equipment for rolling stock - Part 1: General service conditions and general rules

IEC 60077-1:2017 specifies the general service conditions and requirements for all electric equipment installed in power circuits, auxiliary circuits, control and indicating circuits etc., on railway rolling stock. The purpose of this document is to harmonize as far as practicable all rules and requirements of a general nature applicable to electric equipment for rolling stock. This new edition includes the following main technical changes with regard to the previous edition:

- descriptions regarding insulation coordination, environmental conditions and those of current return and protective bonding are deleted and replaced by references to IEC 62497‑1, IEC 62498-1 and IEC 61991;

- classification of equipment type is introduced;

- temperature limits and temperature rise tests are reviewed.

Applications ferroviaires - Equipements électriques du matériel roulant - Partie 1: Conditions générales de service et règles générales

L’IEC 60077-1:2017 spécifie les conditions générales de service et les exigences pour l'ensemble de l'équipement électrique installé dans les circuits de puissance, les circuits auxiliaires, les circuits de commande, les circuits de signalisation et de surveillance, etc., sur le matériel roulant ferroviaire. Le présent document a pour objet d’harmoniser dans la mesure du possible l’ensemble des règles et des exigences de caractère général applicables aux équipements électriques du matériel roulant. Cette nouvelle édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- suppression et remplacement des descriptions concernant la coordination de l’isolement, les conditions d’environnement et celles du retour de courant et de la mise à la masse par des références à l'IEC 62497-1, l'IEC 62498-1 et l'IEC 61991;

- introduction d’une classification de type d’équipement;

- révision des températures limites et des essais d'échauffement.

General Information

- Status

- Published

- Publication Date

- 30-Jul-2017

- Technical Committee

- TC 9 - Electrical equipment and systems for railways

- Drafting Committee

- MT 60077 - TC 9/MT 60077

- Current Stage

- PPUB - Publication issued

- Start Date

- 31-Jul-2017

- Completion Date

- 30-Jun-2017

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60077-1:2017 - Railway applications - Electric equipment for rolling stock - Part 1: General service conditions and general rules - defines the general service conditions and common requirements for all electric equipment fitted to railway rolling stock. It applies to equipment in power circuits, auxiliary circuits, control and indicating circuits, batteries and related installations. The standard aims to harmonize general rules across railway electric equipment and to provide baseline requirements for design, testing and documentation.

Key recent technical updates:

- Insulation coordination, environmental conditions and return/protective bonding references replaced by IEC 62497‑1, IEC 62498‑1 and IEC 61991.

- Classification of equipment types introduced.

- Temperature limits and temperature rise test requirements reviewed.

Key Topics

- Scope and classification of equipment types for rolling stock (clause 4).

- Rated voltages, currents and frequencies for supply, auxiliary and control circuits.

- Normal service conditions (altitude, ambient temperature, humidity, vibration, shock, pollution) and clause-level guidance for operation.

- Thermal requirements: temperature limits for insulation systems, temperature rise tests and thermal endurance (clauses 7 & 8; Annex C contains thermal endurance examples).

- Dielectric and insulation requirements: clearances, creepage distances, impulse and power-frequency withstand voltages (dielectric tests referenced in clause 9 and Annex B).

- Constructional and safety requirements: fire protection, batteries, protective measures against electrical hazards.

- Performance testing: type tests, routine tests, sampling and investigation tests; verification of EMC, acoustic noise, vibration/shock and climatic resistance.

- Product information and marking: required documentation, storage/installation/maintenance instructions.

Applications

IEC 60077-1 is used to:

- Set baseline requirements for the design of transformers, converters, switchgear, contact-line supplied equipment, control systems and auxiliary devices on trains and trams.

- Define test programs for type approval and routine testing in manufacturing and certification.

- Inform procurement specifications and compliance checks for rolling stock electrical systems.

- Guide maintenance and testing regimes by infrastructure managers and maintenance depots.

Who uses this standard

- Rolling stock manufacturers and component designers

- Test laboratories and certification bodies

- Procurement engineers and system integrators in rail industry

- Maintenance engineers and safety compliance teams

Related standards

- IEC 62497‑1, IEC 62498‑1, IEC 61991 (insulation coordination and bonding references)

- Other parts of the IEC 60077 series (for equipment-specific requirements)

Keywords: IEC 60077-1, railway applications, electric equipment for rolling stock, insulation coordination, temperature rise test, creepage distances, clearances, dielectric tests, rolling stock standards.

IEC 60077-1:2017 RLV - Railway applications - Electric equipment for rolling stock - Part 1: General service conditions and general rules Released:7/31/2017 Isbn:9782832246948

IEC 60077-1:2017 - Railway applications - Electric equipment for rolling stock - Part 1: General service conditions and general rules

Frequently Asked Questions

IEC 60077-1:2017 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Railway applications - Electric equipment for rolling stock - Part 1: General service conditions and general rules". This standard covers: IEC 60077-1:2017 specifies the general service conditions and requirements for all electric equipment installed in power circuits, auxiliary circuits, control and indicating circuits etc., on railway rolling stock. The purpose of this document is to harmonize as far as practicable all rules and requirements of a general nature applicable to electric equipment for rolling stock. This new edition includes the following main technical changes with regard to the previous edition: - descriptions regarding insulation coordination, environmental conditions and those of current return and protective bonding are deleted and replaced by references to IEC 62497‑1, IEC 62498-1 and IEC 61991; - classification of equipment type is introduced; - temperature limits and temperature rise tests are reviewed.

IEC 60077-1:2017 specifies the general service conditions and requirements for all electric equipment installed in power circuits, auxiliary circuits, control and indicating circuits etc., on railway rolling stock. The purpose of this document is to harmonize as far as practicable all rules and requirements of a general nature applicable to electric equipment for rolling stock. This new edition includes the following main technical changes with regard to the previous edition: - descriptions regarding insulation coordination, environmental conditions and those of current return and protective bonding are deleted and replaced by references to IEC 62497‑1, IEC 62498-1 and IEC 61991; - classification of equipment type is introduced; - temperature limits and temperature rise tests are reviewed.

IEC 60077-1:2017 is classified under the following ICS (International Classification for Standards) categories: 29.080.01 - Electrical insulation in general; 29.160.01 - Rotating machinery in general; 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60077-1:2017 has the following relationships with other standards: It is inter standard links to IEC 60077-1:1999. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase IEC 60077-1:2017 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of IEC standards.

Standards Content (Sample)

IEC 60077-1 ®

Edition 2.0 2017-07

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Railway applications – Electric equipment for rolling stock –

Part 1: General service conditions and general rules

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60077-1 ®

Edition 2.0 2017-07

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Railway applications – Electric equipment for rolling stock –

Part 1: General service conditions and general rules

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 45.060.01 ISBN 978-2-8322-4694-8

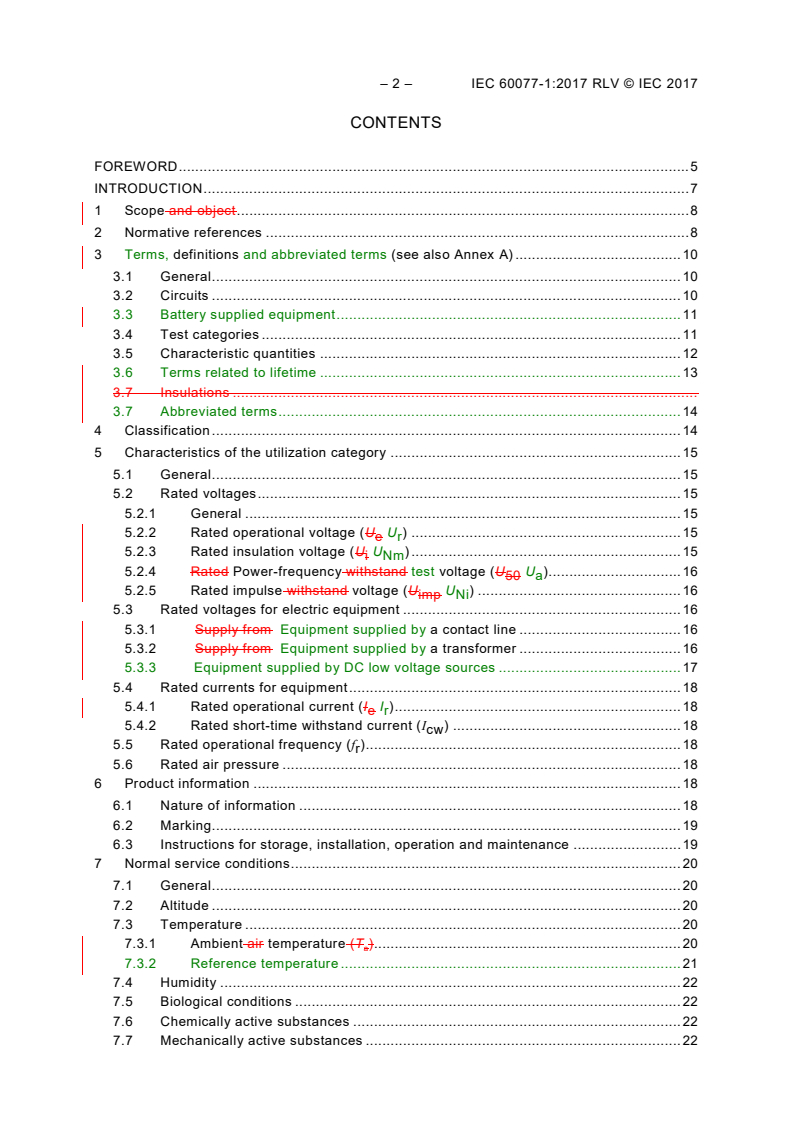

– 2 – IEC 60077-1:2017 RLV © IEC 2017

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope and object . 8

2 Normative references . 8

3 Terms, definitions and abbreviated terms (see also Annex A) . 10

3.1 General . 10

3.2 Circuits . 10

3.3 Battery supplied equipment . 11

3.4 Test categories . 11

3.5 Characteristic quantities . 12

3.6 Terms related to lifetime . 13

3.7 Insulations .

3.7 Abbreviated terms . 14

4 Classification . 14

5 Characteristics of the utilization category . 15

5.1 General . 15

5.2 Rated voltages . 15

5.2.1 General . 15

5.2.2 Rated operational voltage (U U ) . 15

e r

5.2.3 Rated insulation voltage (U U ) . 15

i Nm

5.2.4 Rated Power-frequency withstand test voltage (U U ). 16

50 a

5.2.5 Rated impulse withstand voltage (U U ) . 16

imp Ni

5.3 Rated voltages for electric equipment . 16

5.3.1 Supply from Equipment supplied by a contact line . 16

5.3.2 Supply from Equipment supplied by a transformer . 16

5.3.3 Equipment supplied by DC low voltage sources . 17

5.4 Rated currents for equipment . 18

5.4.1 Rated operational current (I I ) . 18

e r

5.4.2 Rated short-time withstand current (I ) . 18

cw

5.5 Rated operational frequency (f ). 18

r

5.6 Rated air pressure . 18

6 Product information . 18

6.1 Nature of information . 18

6.2 Marking . 19

6.3 Instructions for storage, installation, operation and maintenance . 19

7 Normal service conditions . 20

7.1 General . 20

7.2 Altitude . 20

7.3 Temperature . 20

7.3.1 Ambient air temperature (T ) . 20

a

7.3.2 Reference temperature . 21

7.4 Humidity . 22

7.5 Biological conditions . 22

7.6 Chemically active substances . 22

7.7 Mechanically active substances . 22

7.8 Vibration and shock . 22

7.9 Exposure to pollution . 22

7.10 Exposure to overvoltages . 23

8 Constructional and performance requirements . 24

8.1 Constructional requirements . 24

8.1.1 Protective provisions against electrical hazards . 26

8.1.2 Batteries . 26

8.1.3 Fire protection . 26

8.1.4 Other risks . 26

8.2 Performance requirements . 26

8.2.1 Operating conditions . 26

8.2.2 Temperature rise limits . 28

8.2.3 Operation following inactivity . 34

8.2.4 Electromagnetic compatibility (EMC) . 35

8.2.5 Acoustic noise emission . 35

8.2.6 Clearances . 41

8.2.7 Creepage distances . 41

8.2.8 Switching overvoltages . 41

8.2.9 Operational performance . 41

8.2.10 Ability to withstand vibration and shock . 42

9 Tests . 42

9.1 Kinds of tests . 42

9.1.1 General . 42

9.1.2 Type tests. 42

9.1.3 Routine tests . 43

9.1.4 Sampling tests . 43

9.1.5 Investigation tests. 43

9.1.6 General test condition . 43

9.1.7 Summary of tests . 44

9.2 Verification of constructional requirements . 44

9.2.1 General . 44

9.2.2 Type tests. 44

9.2.3 Routine tests . 45

9.3 Verification of performance requirements . 45

9.3.1 Operating limits and functional tests . 45

9.3.2 Temperature rise test . 46

9.3.3 Dielectric properties . 49

9.3.4 Operational performance capability. 53

9.3.5 Vibration and shock . 55

9.3.6 Electromagnetic compatibility (EMC) . 55

9.3.7 Acoustic noise emission . 55

9.3.8 Climatic tests . 55

Annex A (normative) Measurement of creepage distances and clearances .

Annex A (informative) Coordination between definitions . 62

Annex B (informative) Type and routine test of dielectric tests for equipment . 68

B.1 General . 68

B.2 General conditions . 68

B.3 Test voltage . 68

– 4 – IEC 60077-1:2017 RLV © IEC 2017

Annex C (informative) Clearance and creepage determination .

Annex C (informative) Example of thermal endurance calculation to demonstrate the

suitability of an insulation system for a specified application . 71

C.1 General . 71

C.2 Example 1 – Temperature limits for an electric insulation system . 71

C.3 Example 2 – Thermal endurance calculation . 72

C.3.1 General . 72

C.3.2 Operating conditions provided by the purchaser . 72

C.3.3 Thermal endurance characteristics provided by the manufacturer . 73

C.3.4 Temperature rise test results . 73

C.3.5 Extrapolations . 74

C.3.6 Lifetime calculation based on thermal endurance . 74

C.3.7 Equivalent continuous duty and rated continuous duty . 75

Bibliography . 76

Figure A.1 – Example of relation of limiting values . 64

Figure A.2 – Example of utilization category . 64

Figure A.3 – Example of coordination of operational conditions . 64

Table 1 – Voltage ranges for control circuits and auxiliary circuits. 17

Table 2 – Classes of air temperatures . 21

Table 3 – Temperature limits of electrical insulating system . 32

Table 4 – Determination of rated impulse withstand voltage .

Table 4 – Temperature limits of terminals . 33

Table 5 – Minimum clearances in air .

Table 5 – Temperature limits of accessible parts . 34

Table 6a – Creepages for rated insulation voltages up to 1 000 V .

Table 6b – Creepages for rated insulation voltages above 1 000 V .

Table 6 – List of tests (as appropriate) . 44

Table 7 – Test voltages for verification of clearances .

Table B.1 – Dielectric tests on single pieces of equipment . 69

Table B.2 – Dielectric tests for equipment connected to AC contact line . 70

Table C.1 – Temperature limits and expected lifetime for a dry-type insulation

system (examples) . 72

Table C.2 – Ambient temperature distribution . 73

Table C.3 – Temperature rise test results . 73

Table C.4 – Extrapolation to other ambient temperature . 74

Table C.5 – Lifetime calculation based on thermal endurance . 74

Table C.6 – Equivalent continuous duty and rated continuous duty . 75

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RAILWAY APPLICATIONS –

ELECTRIC EQUIPMENT FOR ROLLING STOCK –

Part 1: General service conditions and general rules

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

– 6 – IEC 60077-1:2017 RLV © IEC 2017

International Standard IEC 60077-1 has been prepared by IEC technical committee 9:

Electrical equipment and systems for railways.

This second edition cancels and replaces the first edition of IEC 60077-1, issued in 1999. It

constitutes a technical revision.

This edition includes the following main technical changes with regard to the previous edition:

a) Descriptions regarding insulation coordination, environmental conditions and those of

current return and protective bonding are deleted and replaced by references to

IEC 62497-1, IEC 62498-1 and IEC 61991, except classes of air temperature, which are

copied from Table 2 in IEC 62498-1:2010.

b) Classification of equipment type is introduced.

c) Temperature limits and temperature rise tests are reviewed.

d) Example of lifetime calculation: Annex C (informative) is introduced.

The text of this standard is based on the following documents:

FDIS Report on voting

9/2266/FDIS 9/2278/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60077 series, published under the general title Railway

applications – Electric equipment for rolling stock, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

INTRODUCTION

Although this document specifies the general service conditions and general rules for electric

equipment for railway rolling stock, further special details of for certain types of traction

electric equipment may be given in other IEC standards. In particular, product standards give

further details and the product standards to be part of the traction series are

IEC 60077: Railway applications – Electric equipment for rolling stock

IEC 60077 series consists of the following parts:

• Part 1 – General service conditions and general rules

• Part 2 – Electrotechnical components – General rules

• Part 3 – Electrotechnical components – Rules for DC circuit-breakers

• Part 4 – Electrotechnical components – Rules for AC circuit-breakers

• Part 5 – Electrotechnical components – Rules for HV fuses

Although all circuits of power or control electronic equipment connected to battery or contact

line voltages, and all circuits comprising switchgear or controlgear are covered by this

document, internal circuits of these may be subject to special requirements covered by

relevant product standards.

For electric equipment for rolling stock which conforms to an appropriate international

standard, including items of industrial equipment, this document, plus the relevant railway

equipment product standard for electric equipment where appropriate, specifies only those

additional requirements to ensure satisfactory operation on rolling stock.

– 8 – IEC 60077-1:2017 RLV © IEC 2017

RAILWAY APPLICATIONS –

ELECTRIC EQUIPMENT FOR ROLLING STOCK –

Part 1: General service conditions and general rules

1 Scope and object

This part of IEC 60077 specifies the general service conditions and requirements for all

electric equipment installed in power circuits, auxiliary circuits, control and indicating circuits

etc., on railway rolling stock.

NOTE Some of these rules may can, after agreement between the user and the manufacturer, be used for

electrical equipment installed on other vehicles other than railway rolling stock, such as mine locomotives, trolley

buses, etc.

The purpose of this document is to harmonize as far as practicable all rules and requirements

of a general nature applicable to electric equipment for rolling stock. This is in order to obtain

uniformity of requirements and tests throughout the corresponding range of equipment to

avoid the need for testing to different standards.

All requirements relating to:

• the environmental stresses expected during the normal service conditions;

• the construction;

• the performance and the associated tests which can be considered as general;

have therefore been gathered in this document together with specific subjects of wide interest

and application, for example temperature rise, dielectric properties, etc.

In the event of there being a difference in requirements between this document and a railway

rolling stock relevant product standard, then the product standard requirements take

precedence.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050(151):1978, International Electrotechnical Vocabulary (IEV) – Chapter 151:

Electrical and magnetic devices

IEC 60050(441):1984, International Electrotechnical Vocabulary (IEV) – Chapter 441:

Switchgear, controlgear and fuses

IEC 60050(811):1991, International Electrotechnical Vocabulary (IEV) – Chapter 811: Electric

traction

IEC 60056:1987, High-voltage alternating-current circuit-breakers

IEC 60068-2-1:1990, Environmental testing – Part 2-1: Tests – Tests A: Cold

IEC 60068-2-2:1974, Environmental testing – Part 2-2: Tests – Tests B: Dry heat

IEC 60068-2-3:1969, Environmental testing – Part 2: Tests – Test Ca: Damp heat, steady

state

IEC 60068-2-30, Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic

(12 h + 12 h cycle)

IEC 60068-2-52:1996, Environmental testing – Part 2-52: Tests – Test Kb: Salt mist, cyclic

(sodium chloride solution)

IEC 60068-2-78, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

IEC 60071-1:1993, Insulation co-ordination – Part 1: Definitions, principles and rules

IEC 60085:1984, Electrical insulation – Thermal evaluation and classification of electrical

insulation designation

IEC 60112:1979, Method for determining the comparative and the proof tracking indices of

solid insulating materials under moist conditions

IEC 60216-1, Electrical insulating materials – Thermal endurance properties – Part 1: Ageing

procedures and evaluation of test results

IEC 60364-4-41:1992, Electrical installations of buildings – Part 4: Protection for safety –

Chapter 41: Protection against electric shock

IEC 60505, Evaluation and qualification of electrical insulation systems

IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

IEC/TR 60536:1976, Classification of electrical and electronic equipment with regard to

protection against electric shock

IEC 60587:1984, Test method for evaluating resistance to tracking and erosion of electrical

insulating materials used under severe ambient conditions

IEC 60664-1:1992, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

IEC 60721-3-5:1997, Classification of environmental conditions – Part 3: Classification of

groups of environmental parameters and their severities – Section 5: Ground vehicle

installations

IEC 60850:1988, Railway applications – Supply voltages of traction systems

IEC 61133:1992 2016, Electric traction Railway applications – Rolling stock – Testing

methods for electric and thermal/electric of rolling stock on completion of construction and

before entry into service

IEC 61373:1999, Railway applications – Rolling stock equipment – Shock and vibration tests

IEC 61991, Railway applications – Rolling stock – Protective provisions against electrical

hazards

– 10 – IEC 60077-1:2017 RLV © IEC 2017

IEC 61992-1, Railway applications – Fixed installations – DC switchgear – Part 1: General

IEC 62236-3-2, Railway applications – Electromagnetic compatibility – Part 3-2: Rolling stock

– Apparatus

IEC 62497-1, Railway applications – Insulation coordination – Part 1: Basic requirements –

Clearances and creepage distances for all electrical and electronic equipment

IEC 62498-1:2010, Railway applications – Environmental conditions for equipment – Part 1:

Equipment on board rolling stock

3 Terms, definitions and abbreviated terms (see also Annex A)

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 General

3.1.1

rolling stock

general term covering all the vehicles with or without motors

Note 1 to entry: Examples of vehicles include a locomotive, a coach and a wagon.

[SOURCE: IEC 60050-811:2017, 811-02-01]

3.1.2

vehicle

general term denoting any single item of rolling stock, e.g. a locomotive, a coach or a wagon

[IEV 811-02-02]

3.2 Circuits

3.2.1

power circuit

circuit carrying the current of the machines and equipment, such as the converters and

traction motors, which transmit the traction output

[SOURCE: IEC 60050-811:2017, 811-25-03]

3.2.2

main circuit

all the conductive parts of a device carrying the current for the function to which this device

has been applied

3.2.3

auxiliary circuit,

circuit carrying the current of the auxiliaries such as the compressors and fans

[SOURCE: IEC 60050-811:2017, 811-25-05]

3.2.4

control circuit,

circuit used to actuate the power or auxiliary equipment

[SOURCE: IEC 60050-811:2017, 811-25-12]

3.2.5

indicating circuit

circuit transmitting a signal indicating or recording whether a particular operating condition

exists or not (for example a signal indicating a failure in the electrical equipment)

[SOURCE: IEC 60050-811:2017, 811-25-14]

3.3 Battery supplied equipment

3.3.1

battery

electrochemical system capable of storing in chemical form the electric energy received and

which can give it back by reconversion

[IEV 811-20-01]

3.3.2

battery on float

secondary battery whose terminals are permanently connected to a source of constant

voltage sufficient to maintain the battery approximately fully charged, and which is intended to

supply power to an electric circuit, if the normal supply is temporarily interrupted

Note 1 to entry: The battery is absorbing a float charge current in this mode.

[SOURCE: IEC 60050-482:2004, 482-05-35, modified – Note 1 to entry has been added.]

3.3.3

float charge battery system

equipment mostly operated with the battery on float charge

3.3.4

battery off charge system

equipment mostly supplied while the battery is not being charged

3.4 Test categories

3.4.1

type test

test of one or more devices made to a certain design to show that the design meets certain

specifications

conformity test made on one or more items representative of the production

[SOURCE: IEC 60050-811:2017, 811-10-04]

3.4.2

routine test

a test to which each individual device is subjected during or after manufacture to ascertain

whether it complies with certain criteria

conformity test made on each individual item during or after manufacture

[SOURCE: IEC 60050-811:2017, 811-10-05]

– 12 – IEC 60077-1:2017 RLV © IEC 2017

3.4.3

sampling test

test on a number of devices taken at random from a batch a sample

[SOURCE: IEC 60050-811:2017, 811-10-06]

3.4.4

investigation test

special test of an optional character carried out in order to obtain additional information

[SOURCE: IEC 60050-811:2017, 811-10-07]

3.4.5

exposed conductive part

conductive part which can readily be touched and which is not normally alive, but which may

become alive under fault conditions

[SOURCE: IEC 60050-441:1984, 441-11-10, modified – Note has been deleted.]

3.5 Characteristic quantities

3.5.1

limiting value

greatest or smallest admissible value of a quantity in a specification of a component, device,

equipment, or system

[IEV 151-04-02]

[SOURCE: IEC 60050-151:2001, 151-16-10, modified – The order of phrases has been

changed.]

3.5.2

nominal value

suitable approximate quantity value used to designate or identify a characteristic of a

component, device or equipment

value of a quantity used to designate and identify a component, device, equipment, or system

Note 1 to entry: The nominal value is generally a rounded value.

Note 2 to entry: In this document, the term "nominal" is used only as common practice to designate contact line

and battery voltage circuits.

[SOURCE: IEC 60050-811:2017, 811-11-01, modified – Note 2 to entry has been added.]

3.5.3

rated value

quantity value assigned, generally by a manufacturer, for a specified operating condition of a

component, device or equipment

value of a quantity used for specification purposes, established for a specified set of operating

conditions of a component, device, equipment, or system

[SOURCE: IEC 60050-811:2017, 811-11-02]

3.6.4

working voltage

highest r.m.s. value of the a.c. voltage or the highest value of the d.c. voltage which may

occur (locally) across any insulation at rated supply voltage, transients being disregarded, in

open-circuit conditions or under normal operating conditions

NOTE – The working voltage of an internal part of an equipment may be different from the supply voltage, for

example if:

– a part of an equipment is considered (after transformer, converter);

– the circuit conductor is not directly connected to the vehicle structure;

– the voltage is a part of supply voltage (components in series);

– secondary insulation or double insulation is considered.

3.5.4

equivalent continuous duty

duty of electrical equipment on rolling stock, which corresponds to the actual service,

generally characterized by values of current, voltage, compressed air pressure, etc., which

vary with time

Note 1 to entry: The various parts of the equipment are defined by a complete statement of the conditions to be

fulfilled. However, it is sometimes sufficient to specify an equivalent duty which corresponds from the point of view

of either electrical, mechanical or thermal stresses to the service considered, and is known as being equivalent to

the actual service. It is the equivalent continuous duty to which the relevant tests are referred.

3.5.5

equivalent continuous rated current

current corresponding to the equivalent continuous duty

3.6.7

equivalent continuous rated voltage

voltage corresponding to the equivalent continuous duty

3.6 Terms related to lifetime

3.6.1

ageing

change with passage of time of physical, chemical or electrical properties of a component or

module under specified operating conditions, which may result in degradation of significant

performance characteristics

Note 1 to entry: This entry was numbered 393-18-41 in IEC 60050-393:2003.

[SOURCE: IEC 60050-395:2014, 395-07-100]

3.6.2

endurance

ability to withstand the action of ageing factors

Note 1 to entry: The endurance may be characterized by the results of accelerated ageing tests.

[SOURCE: IEC 60050-212:2010, 212-12-08]

3.6.3

thermal endurance

ability to withstand the action of temperature

[SOURCE: IEC 60050-212:2010, 212-12-09]

3.6.4

durability

ability to perform as required, under given conditions of use and maintenance, until the end of

useful life

Note 1 to entry: For the purpose of this document, "durability" is used in order to express the expectancy of the

life duration (time or number of operating cycles) which can be performed by the equipment before repair or

replacement of parts.

– 14 – IEC 60077-1:2017 RLV © IEC 2017

[SOURCE: IEC 60050-192:2015, 192-01-21, modified – Note 1 to entry has been added.]

3.7 Insulations

3.7.1

functional insulation

insulation between conductive parts which is necessary only for the proper functioning of the

equipment

3.7.2

basic insulation

insulation of live parts to provide basic protection against electric shock (human safety)

NOTE – Basic insulation does not necessarily include insulation used exclusively for functional purposes (see 2.1

of IEC 60536).

3.7.3

supplementary insulation

independent insulation applied in addition to basic insulation, in order to provide protection

against electric shock in the event of a failure of basic insulation [IEC 60536, 2.2]

3.7.4

reinforced insulation

single insulation system applied to live parts, which provides a degree of protection against

electric shock equivalent to double insulation under the conditions specified in the relevant

IEC standard [IEC 60536, 2.4]

NOTE – A single insulation system does not imply that the insulation must be one homogeneous piece. It may

comprise several layers which cannot be tested singly as basic or supplementary insulation.

3.7.5

double insulation

two-stage insulation, the first being between the live conductors and an intermediate frame

and the second between the intermediate frame and the body of the vehicle [IEV 811-27-15]

3.7 Abbreviated terms

AC Alternating Current

DC Direct Current

EMC Electromagnetic Compatibility

RMS Root Mean Square value

PD Pollution degree

OV Overvoltage category

VC Voltage Class

4 Classification

This clause is intended to list the characteristics of equipment on which information may be

given by the manufacturer and which may not necessarily have to shall be verified by testing

where relevant.

This clause is not mandatory in product standards which should however leave space for it in

order to list, where necessary, classification criteria.

Equipment covered by this document is classified, according to the supply source of its

control and auxiliary circuits. Details are given in 5.3.3.2.

5 Characteristics of the utilization category

5.1 General

The utilization category of equipment defines the intended application and shall be specified

in the relevant product standard; it is characterized by one or more of the following

parameters:

• current(s);

• voltage(s);

• frequency(ies);

• air pressure(s).

See also Annex A.

NOTE This list is not exhaustive and can include other parameters as applicable.

5.2 Rated voltages

5.2.1 General

The term rated voltage can generally be related to both the input and output values of

equipment. The quantity is assigned generally by the manufacturer.

5.2.2 Rated operational voltage (U U )

e r

The rated operational voltage of equipment is a value of voltage which combined with a rated

operational current and rated operational frequency, determines the application of the

equipment and to which the relevant tests and the utilization categories are referred.

NOTE Symbol U was used in the first edition of IEC 60077-1. U is used in IEC 61992-1.

e Ne

5.2.3 Rated insulation voltage (U U )

i Nm

Definition of a rated insulation voltage is given in IEC 62497-1.

The rated insulation voltage is the value of voltage to which dielectric tests rated impulse

voltage and creepage distances are referred.

In no case shall the maximum value of the working voltage or the rated operational voltage

exceed that of the rated insulation voltage.

The rated insulation voltage is at least equal to the highest r.m.s. value of the voltage existing

between electrodes and across the creepage distance for an extended period of time e.g. for

a contact line greater than 5 mm. Non-repetitive transient voltages are neglected.

When the voltage is not purely of sinusoidal or of continuous form, the RMS or mean value

alone cannot be considered to prescribe the rated insulation voltage of the components.

In the absence of any knowledge of the influence on dielectric strength of:

• the ratio between the duration of periodic impulses and their occurrence repetition period;

• the number of impulses during each occurrence burst;

• the voltage rate of rise of the impulse (dv/dt),

it is recommended that this voltage be considered as being equal to the real RMS value, but

not less than 70 % of the peak value.

– 16 – IEC 60077-1:2017 RLV © IEC 2017

5.2.4 Rated Power-frequency withstand test voltage (U U )

50 a

The rated power-frequency withstand test voltage is the RMS value of power-frequency

sinusoidal voltage which does not cause an insulation failure under specified conditions of

test.

U is given in IEC 62497-1.

a

5.2.5 Rated impulse withstand voltage (U U )

imp Ni

The rated impulse withstand voltage is the highest peak value of an impulse voltage, of

prescribed form and polarity, the equ

...

IEC 60077-1 ®

Edition 2.0 2017-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Railway applications – Electric equipment for rolling stock –

Part 1: General service conditions and general rules

Applications ferroviaires – Equipements électriques du matériel roulant –

Partie 1: Conditions générales de service et règles générales

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

65 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60077-1 ®

Edition 2.0 2017-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Railway applications – Electric equipment for rolling stock –

Part 1: General service conditions and general rules

Applications ferroviaires – Equipements électriques du matériel roulant –

Partie 1: Conditions générales de service et règles générales

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 45.060.01 ISBN 978-2-8322-4422-7

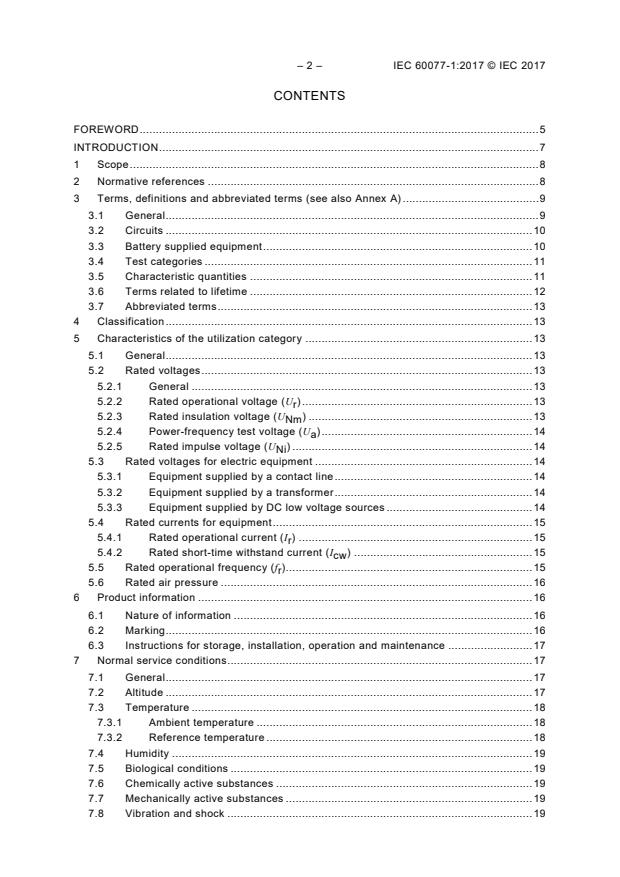

– 2 – IEC 60077-1:2017 © IEC 2017

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms, definitions and abbreviated terms (see also Annex A) . 9

3.1 General . 9

3.2 Circuits . 10

3.3 Battery supplied equipment . 10

3.4 Test categories . 11

3.5 Characteristic quantities . 11

3.6 Terms related to lifetime . 12

3.7 Abbreviated terms . 13

4 Classification . 13

5 Characteristics of the utilization category . 13

5.1 General . 13

5.2 Rated voltages . 13

5.2.1 General . 13

5.2.2 Rated operational voltage (U ) . 13

r

5.2.3 Rated insulation voltage (U ) . 13

Nm

5.2.4 Power-frequency test voltage (U ) . 14

a

5.2.5 Rated impulse voltage (U ) . 14

Ni

5.3 Rated voltages for electric equipment . 14

5.3.1 Equipment supplied by a contact line . 14

5.3.2 Equipment supplied by a transformer . 14

5.3.3 Equipment supplied by DC low voltage sources . 14

5.4 Rated currents for equipment . 15

5.4.1 Rated operational current (I ) . 15

r

5.4.2 Rated short-time withstand current (I ) . 15

cw

5.5 Rated operational frequency (f ). 15

r

5.6 Rated air pressure . 16

6 Product information . 16

6.1 Nature of information . 16

6.2 Marking . 16

6.3 Instructions for storage, installation, operation and maintenance . 17

7 Normal service conditions . 17

7.1 General . 17

7.2 Altitude . 17

7.3 Temperature . 18

7.3.1 Ambient temperature . 18

7.3.2 Reference temperature . 18

7.4 Humidity . 19

7.5 Biological conditions . 19

7.6 Chemically active substances . 19

7.7 Mechanically active substances . 19

7.8 Vibration and shock . 19

7.9 Exposure to pollution . 19

7.10 Exposure to overvoltages . 19

8 Constructional and performance requirements . 19

8.1 Constructional requirements . 19

8.1.1 Protective provisions against electrical hazards . 19

8.1.2 Batteries . 20

8.1.3 Fire protection . 20

8.1.4 Other risks . 20

8.2 Performance requirements . 20

8.2.1 Operating conditions . 20

8.2.2 Temperature limits . 22

8.2.3 Operation following inactivity . 26

8.2.4 Electromagnetic compatibility (EMC) . 27

8.2.5 Acoustic noise emission . 27

8.2.6 Clearances . 27

8.2.7 Creepage distances . 27

8.2.8 Switching overvoltages . 27

8.2.9 Operational performance . 27

8.2.10 Ability to withstand vibration and shock . 28

9 Tests . 28

9.1 Kinds of tests . 28

9.1.1 General . 28

9.1.2 Type tests. 28

9.1.3 Routine tests . 28

9.1.4 Sampling tests . 29

9.1.5 Investigation tests. 29

9.1.6 General test condition . 29

9.1.7 Summary of tests . 29

9.2 Verification of constructional requirements . 30

9.2.1 General . 30

9.2.2 Type tests. 30

9.2.3 Routine tests . 31

9.3 Verification of performance requirements . 31

9.3.1 Operating limits and functional tests . 31

9.3.2 Temperature rise test . 32

9.3.3 Dielectric properties . 35

9.3.4 Operational performance capability. 36

9.3.5 Vibration and shock . 39

9.3.6 Electromagnetic compatibility (EMC) . 39

9.3.7 Acoustic noise emission . 39

9.3.8 Climatic tests . 39

Annex A (informative) Coordination between definitions . 40

Annex B (informative) Type and routine test of dielectric tests for equipment . 42

B.1 General . 42

B.2 General conditions . 42

B.3 Test voltage . 42

Annex C (informative) Example of thermal endurance calculation to demonstrate the

suitability of an insulation system for a specified application . 45

– 4 – IEC 60077-1:2017 © IEC 2017

C.1 General . 45

C.2 Example 1 – Temperature limits for an electric insulation system . 45

C.3 Example 2 – Thermal endurance calculation . 46

C.3.1 General . 46

C.3.2 Operating conditions provided by the purchaser . 46

C.3.3 Thermal endurance characteristics provided by the manufacturer . 47

C.3.4 Temperature rise test results . 47

C.3.5 Extrapolations . 47

C.3.6 Lifetime calculation based on thermal endurance . 48

C.3.7 Equivalent continuous duty and rated continuous duty . 49

Bibliography . 50

Figure A.1 – Example of relation of limiting values . 41

Figure A.2 – Example of utilization category . 41

Figure A.3 – Example of coordination of operational conditions . 41

Table 1 – Voltage ranges for control circuits and auxiliary circuits. 15

Table 2 – Classes of air temperatures . 18

Table 3 – Temperature limits of electrical insulating system . 24

Table 4 – Temperature limits of terminals . 25

Table 5 – Temperature limits of accessible parts . 26

Table 6 – List of tests (as appropriate) . 30

Table B.1 – Dielectric tests on single pieces of equipment . 43

Table B.2 – Dielectric tests for equipment connected to AC contact line . 44

Table C.1 – Temperature limits and expected lifetime for a dry-type insulation system

(examples) . 46

Table C.2 – Ambient temperature distribution . 47

Table C.3 – Temperature rise test results . 47

Table C.4 – Extrapolation to other ambient temperature . 48

Table C.5 – Lifetime calculation based on thermal endurance . 48

Table C.6 – Equivalent continuous duty and rated continuous duty . 49

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RAILWAY APPLICATIONS –

ELECTRIC EQUIPMENT FOR ROLLING STOCK –

Part 1: General service conditions and general rules

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60077-1 has been prepared by IEC technical committee 9:

Electrical equipment and systems for railways.

This second edition cancels and replaces the first edition of IEC 60077-1, issued in 1999. It

constitutes a technical revision.

This edition includes the following main technical changes with regard to the previous edition:

a) Descriptions regarding insulation coordination, environmental conditions and those of

current return and protective bonding are deleted and replaced by references to

IEC 62497-1, IEC 62498-1 and IEC 61991, except classes of air temperature, which are

copied from Table 2 in IEC 62498-1:2010.

b) Classification of equipment type is introduced.

c) Temperature limits and temperature rise tests are reviewed.

– 6 – IEC 60077-1:2017 © IEC 2017

d) Example of lifetime calculation: Annex C (informative) is introduced.

The text of this standard is based on the following documents:

FDIS Report on voting

9/2266/FDIS 9/2278/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60077 series, published under the general title Railway

applications – Electric equipment for rolling stock, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

INTRODUCTION

Although this document specifies the general service conditions and general rules for electric

equipment for railway rolling stock, further details for certain types of electric equipment may

be given in other IEC standards.

IEC 60077 series consists of the following parts:

• Part 1 – General service conditions and general rules

• Part 2 – Electrotechnical components – General rules

• Part 3 – Electrotechnical components – Rules for DC circuit-breakers

• Part 4 – Electrotechnical components – Rules for AC circuit-breakers

• Part 5 – Electrotechnical components – Rules for HV fuses

Although all circuits of power or control electronic equipment connected to battery or contact

line are covered by this document, internal circuits of these may be subject to special

requirements covered by relevant product standards.

For electric equipment for rolling stock which conforms to an appropriate international

standard, including items of industrial equipment, this document, plus the relevant equipment

product standard for electric equipment where appropriate, specifies only those additional

requirements to ensure satisfactory operation on rolling stock.

– 8 – IEC 60077-1:2017 © IEC 2017

RAILWAY APPLICATIONS –

ELECTRIC EQUIPMENT FOR ROLLING STOCK –

Part 1: General service conditions and general rules

1 Scope

This part of IEC 60077 specifies the general service conditions and requirements for all

electric equipment installed in power circuits, auxiliary circuits, control and indicating circuits

etc., on railway rolling stock.

NOTE Some of these rules can, after agreement between the user and the manufacturer, be used for electrical

equipment installed on vehicles other than railway rolling stock, such as mine locomotives, trolley buses, etc.

The purpose of this document is to harmonize as far as practicable all rules and requirements

of a general nature applicable to electric equipment for rolling stock. This is in order to obtain

uniformity of requirements and tests throughout the corresponding range of equipment to

avoid the need for testing to different standards.

All requirements relating to:

• the environmental stresses expected during the normal service conditions;

• the construction;

• the performance and the associated tests which can be considered as general;

have therefore been gathered in this document together with specific subjects of wide interest

and application, for example temperature rise, dielectric properties, etc.

In the event of there being a difference in requirements between this document and a railway

rolling stock relevant product standard, then the product standard requirements take

precedence.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-2-1, Environmental testing – Part 2-1: Tests – Tests A: Cold

IEC 60068-2-2, Environmental testing – Part 2-2: Tests – Tests B: Dry heat

IEC 60068-2-30, Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic

(12 h + 12 h cycle)

IEC 60068-2-52, Environmental testing – Part 2-52: Tests – Test Kb: Salt mist, cyclic (sodium

chloride solution)

IEC 60068-2-78, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady

state

IEC 60085, Electrical insulation – Thermal evaluation and designation

IEC 60216-1, Electrical insulating materials – Thermal endurance properties – Part 1: Ageing

procedures and evaluation of test results

IEC 60505, Evaluation and qualification of electrical insulation systems

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 60721-3-5, Classification of environmental conditions – Part 3: Classification of groups of

environmental parameters and their severities – Section 5: Ground vehicle installations

IEC 60850, Railway applications – Supply voltages of traction systems

IEC 61133:2016, Railway applications – Rolling stock – Testing of rolling stock on completion

of construction and before entry into service

IEC 61373, Railway applications – Rolling stock equipment – Shock and vibration tests

IEC 61991, Railway applications – Rolling stock – Protective provisions against electrical

hazards

IEC 61992-1, Railway applications – Fixed installations – DC switchgear – Part 1: General

IEC 62236-3-2, Railway applications – Electromagnetic compatibility – Part 3-2: Rolling stock

– Apparatus

IEC 62497-1, Railway applications – Insulation coordination – Part 1: Basic requirements –

Clearances and creepage distances for all electrical and electronic equipment

IEC 62498-1:2010, Railway applications – Environmental conditions for equipment – Part 1:

Equipment on board rolling stock

3 Terms, definitions and abbreviated terms (see also Annex A)

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 General

3.1.1

rolling stock

all the vehicles with or without motors

Note 1 to entry: Examples of vehicles include a locomotive, a coach and a wagon.

[SOURCE: IEC 60050-811:2017, 811-02-01]

3.1.2

vehicle

single item of rolling stock

– 10 – IEC 60077-1:2017 © IEC 2017

3.2 Circuits

3.2.1

power circuit

circuit carrying the current of the machines and equipment, such as the converters and

traction motors, which transmit the traction output

[SOURCE: IEC 60050-811:2017, 811-25-03]

3.2.2

main circuit

all the conductive parts of a device carrying the current for the function to which this device

has been applied

3.2.3

auxiliary circuit,

circuit carrying the current of the auxiliaries such as the compressors and fans

[SOURCE: IEC 60050-811:2017, 811-25-05]

3.2.4

control circuit,

circuit used to actuate the power or auxiliary equipment

[SOURCE: IEC 60050-811:2017, 811-25-12]

3.2.5

indicating circuit

circuit transmitting a signal indicating or recording whether a particular operating condition

exists or not (for example a signal indicating a failure in the electrical equipment)

[SOURCE: IEC 60050-811:2017, 811-25-14]

3.3 Battery supplied equipment

3.3.1

battery

electrochemical system capable of storing in chemical form the electric energy received and

which can give it back by reconversion

3.3.2

battery on float

secondary battery whose terminals are permanently connected to a source of constant

voltage sufficient to maintain the battery approximately fully charged, and which is intended to

supply power to an electric circuit, if the normal supply is temporarily interrupted

Note 1 to entry: The battery is absorbing a float charge current in this mode.

[SOURCE: IEC 60050-482:2004, 482-05-35, modified – Note 1 to entry has been added.]

3.3.3

float charge battery system

equipment mostly operated with the battery on float charge

3.3.4

battery off charge system

equipment mostly supplied while the battery is not being charged

3.4 Test categories

3.4.1

type test

conformity test made on one or more items representative of the production

[SOURCE: IEC 60050-811:2017, 811-10-04]

3.4.2

routine test

conformity test made on each individual item during or after manufacture

[SOURCE: IEC 60050-811:2017, 811-10-05]

3.4.3

sampling test

test on a sample

[SOURCE: IEC 60050-811:2017, 811-10-06]

3.4.4

investigation test

special test of an optional character carried out in order to obtain additional information

[SOURCE: IEC 60050-811:2017, 811-10-07]

3.4.5

exposed conductive part

conductive part which can readily be touched and which is not normally alive, but which may

become alive under fault conditions

[SOURCE: IEC 60050-441:1984, 441-11-10, modified – Note has been deleted.]

3.5 Characteristic quantities

3.5.1

limiting value

greatest or smallest admissible value of a quantity in a specification of a component, device,

equipment, or system

[SOURCE: IEC 60050-151:2001, 151-16-10, modified – The order of phrases has been

changed.]

3.5.2

nominal value

value of a quantity used to designate and identify a component, device, equipment, or system

Note 1 to entry: The nominal value is generally a rounded value.

Note 2 to entry: In this document, the term "nominal" is used only as common practice to designate contact line

and battery voltage circuits.

[SOURCE: IEC 60050-811:2017, 811-11-01, modified – Note 2 to entry has been added.]

– 12 – IEC 60077-1:2017 © IEC 2017

3.5.3

rated value

value of a quantity used for specification purposes, established for a specified set of operating

conditions of a component, device, equipment, or system

[SOURCE: IEC 60050-811:2017, 811-11-02]

3.5.4

equivalent continuous duty

duty of electrical equipment on rolling stock, which corresponds to the actual service,

generally characterized by values of current, voltage, compressed air pressure, etc., which

vary with time

Note 1 to entry: The various parts of the equipment are defined by a complete statement of the conditions to be

fulfilled. However, it is sometimes sufficient to specify an equivalent duty which corresponds from the point of view

of either electrical, mechanical or thermal stresses to the service considered, and is known as being equivalent to

the actual service. It is the equivalent continuous duty to which the relevant tests are referred.

3.5.5

equivalent continuous rated current

current corresponding to the equivalent continuous duty

3.6 Terms related to lifetime

3.6.1

ageing

change with passage of time of physical, chemical or electrical properties of a component or

module under specified operating conditions, which may result in degradation of significant

performance characteristics

Note 1 to entry: This entry was numbered 393-18-41 in IEC 60050-393:2003.

[SOURCE: IEC 60050-395:2014, 395-07-100]

3.6.2

endurance

ability to withstand the action of ageing factors

Note 1 to entry: The endurance may be characterized by the results of accelerated ageing tests.

[SOURCE: IEC 60050-212:2010, 212-12-08]

3.6.3

thermal endurance

ability to withstand the action of temperature

[SOURCE: IEC 60050-212:2010, 212-12-09]

3.6.4

durability

ability to perform as required, under given conditions of use and maintenance, until the end of

useful life

Note 1 to entry: For the purpose of this document, "durability" is used in order to express the expectancy of the

life duration (time or number of operating cycles) which can be performed by the equipment before repair or

replacement of parts.

[SOURCE: IEC 60050-192:2015, 192-01-21, modified – Note 1 to entry has been added.]

3.7 Abbreviated terms

AC Alternating Current

DC Direct Current

EMC Electromagnetic Compatibility

RMS Root Mean Square value

PD Pollution degree

OV Overvoltage category

VC Voltage Class

4 Classification

This clause is intended to list the characteristics of equipment on which information may be

given by the manufacturer and which shall be verified by testing where relevant.

Equipment covered by this document is classified, according to the supply source of its

control and auxiliary circuits. Details are given in 5.3.3.2.

5 Characteristics of the utilization category

5.1 General

The utilization category of equipment defines the intended application and shall be specified

in the relevant product standard; it is characterized by one or more of the following

parameters:

• current(s);

• voltage(s);

• frequency(ies);

• air pressure(s).

See also Annex A.

NOTE This list is not exhaustive and can include other parameters as applicable.

5.2 Rated voltages

5.2.1 General

The term rated voltage can generally be related to both the input and output values of

equipment. The quantity is assigned generally by the manufacturer.

5.2.2 Rated operational voltage (U )

r

The rated operational voltage of equipment is a value of voltage which combined with a rated

operational current and rated operational frequency, determines the application of the

equipment and to which the relevant tests and the utilization categories are referred.

NOTE Symbol U was used in the first edition of IEC 60077-1. U is used in IEC 61992-1.

e Ne

5.2.3 Rated insulation voltage (U )

Nm

Definition of a rated insulation voltage is given in IEC 62497-1.

The rated insulation voltage is the value of voltage to which rated impulse voltage and

creepage distances are referred.

– 14 – IEC 60077-1:2017 © IEC 2017

When the voltage is not purely of sinusoidal or of continuous form, the RMS or mean value

alone cannot be considered to prescribe the rated insulation voltage of the components.

In the absence of any knowledge of the influence on dielectric strength of:

• the ratio between the duration of periodic impulses and their repetition period;

• the number of impulses during each burst;

• the voltage rate of rise of the impulse (dv/dt),

it is recommended that this voltage be considered as being equal to the real RMS value, but

not less than 70 % of the peak value.

5.2.4 Power-frequency test voltage (U )

a

The power-frequency test voltage is the RMS value of power-frequency sinusoidal voltage

which does not cause an insulation failure under specified conditions of test.

U is given in IEC 62497-1.

a

5.2.5 Rated impulse voltage (U )

Ni

Definition of a rated impulse voltage is given in IEC 62497-1.

The rated impulse voltage is used for determining minimum required clearances and dielectric

test voltages.

5.3 Rated voltages for electric equipment

5.3.1 Equipment supplied by a contact line

The rated operational voltage (U ) for equipment supplied from the contact line is the highest

r

permanent voltage (U ) of the contact line voltage as defined by IEC 60850.

max1

5.3.2 Equipment supplied by a transformer

The rated operational voltage (U ) for equipment supplied from a winding of a transformer is

r

equal to the RMS voltage at the terminals of the winding when the transformer primary is

supplied at the rated operational voltage. If a second transformer is interposed between the

above-mentioned transformer and the equipment, the rated operational voltage (U ) is equal

r

to the above-mentioned rated operational voltage multiplied by the transformer ratio of the

second transformer.

5.3.3 Equipment supplied by DC low voltage sources

5.3.3.1 Nominal voltages

This subclause applies to the equipment supplied from the voltage bands I and band II

according to IEC 61991.

The nominal voltage (U ) is only used to designate the circuits and the equipment and should

n

be selected from the following preferred values:

24 V, 72 V or 110 V

Other voltages may be used upon agreement between the user and the manufacturer.

NOTE These nominal voltage values are given only as standardizing values for the design of the equipment. They

are not considered as the off-load battery voltage which will be determined as functions of the type of battery, the