EN 1822-5:2009

(Main)High efficiency air filters (EPA, HEPA and ULPA) - Part 5: Determining the efficiency of filter elements

High efficiency air filters (EPA, HEPA and ULPA) - Part 5: Determining the efficiency of filter elements

This European Standard applies to efficient particulate air filters (EPA), high efficiency particulate air filters (HEPA) and ultra low penetration air filters (ULPA) used in the field of ventilation and air conditioning and for technical processes, e.g. for applications in clean room technology or pharmaceutical industry.

It establishes a procedure for the determination of the efficiency on the basis of a particle counting method using a liquid test aerosol, and allows a standardized classification of these filters in terms of their efficiency.

This part of the EN 1822 series deals with measuring the efficiency of filter elements, specifying the conditions and procedures for carrying out tests, describing a specimen test apparatus and its components, and including the method for evaluating test results.

Schwebstofffilter (EPA, HEPA und ULPA) - Teil 5: Abscheidegradprüfung des Filterelements

Diese Europäische Norm gilt für Hochleistungs-Partikelfilter (EPA) Schwebstofffilter (HEPA) und

Hochleistungs-Schwebstofffilter (ULPA) im Bereich der Raum- und Prozesslufttechnik, z. B. Anwendungen in

der Reinraumtechnik oder in der pharmazeutischen Industrie.

Sie legt ein Verfahren zur Prüfung des Abscheidegrades auf Basis von Partikelzählverfahren unter Verwendung

eines flüssigen Prüfaerosols fest und ermöglicht eine einheitliche Klassifizierung der Schwebstofffilter

nach dem Abscheidegrad.

Dieser Teil der Normenreihe EN 1822 behandelt die Abscheidegradprüfung von Filterelementen mit Angabe

der Bedingungen und Verfahren zur Durchführung der Prüfung sowie mit der Beschreibung eines Prüfgerätes

einschließlich ihrer Komponenten und des Verfahrens zur Auswertung der Messergebnisse.

Filtres à air à haute efficacité (EPA, HEPA et ULPA) - Partie 5: Mesure de l'efficacité de l'élément filtrant

La présente Norme européenne est applicable aux filtres à air à haute efficacité (EPA), à très haute efficacité (HEPA) et à très faible pénétration (ULPA), utilisés dans le domaine de la ventilation et de la climatisation ainsi que dans des procédés techniques, tels que les applications en salle blanche ou de l'industrie pharmaceutique.

Elle définit une méthode de détermination de l'efficacité, à partir d'une méthode du comptage de particules à l'aide d'un aérosol d'essai liquide et permet une classification normalisée de ces filtres en fonction de leur efficacité.

Cette partie de la série des EN 1822 traite de la mesure de l'efficacité des éléments filtrants, elle spécifie les conditions et les modes opératoires des essais, décrit un exemple d'appareillage d'essai et ses éléments, et inclut la méthode d'évaluation des résultats d'essai.

Visoko učinkoviti zračni filtri (EPA, HEPA in ULPA) - 5. del: Določanje učinkovitosti filtrskih elementov

Ta evropski standard velja za učinkovite zračne filtre drobnih delcev (EPA), visoko učinkovite zračne filtre drobnih delcev (HEPA) in zračne filtre z ultra nizko penetracijo (ULPA), ki se uporabljajo na področju prezračevanja in klimatizacije ter za tehnične postopke, npr. za naprave v tehnologiji čistega prostora ali farmacevtski industriji. Vzpostavlja postopek za določitev učinkovitosti na osnovi metode štetja delcev z uporabo tekočega testnega aerosola ter omogoča standardizirano klasifikacijo teh filtrov glede na njihovo učinkovitost. Ta del serije EN 1822 obravnava merjenje učinkovitosti filtrskih elementov, določa pogoje in postopke za opravljanje preskusov, opisuje vzorčno opremo za preskušanje in njene komponente ter vključuje metodo za vrednotenje rezultatov preskusa.

General Information

- Status

- Withdrawn

- Publication Date

- 17-Nov-2009

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 195 - Air filters for general air cleaning

- Drafting Committee

- CEN/TC 195/WG 2 - HEPA and ULPA filters

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Oct-2018

- Completion Date

- 14-Apr-2025

Relations

- Effective Date

- 21-Nov-2009

- Effective Date

- 12-Oct-2016

Frequently Asked Questions

EN 1822-5:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "High efficiency air filters (EPA, HEPA and ULPA) - Part 5: Determining the efficiency of filter elements". This standard covers: This European Standard applies to efficient particulate air filters (EPA), high efficiency particulate air filters (HEPA) and ultra low penetration air filters (ULPA) used in the field of ventilation and air conditioning and for technical processes, e.g. for applications in clean room technology or pharmaceutical industry. It establishes a procedure for the determination of the efficiency on the basis of a particle counting method using a liquid test aerosol, and allows a standardized classification of these filters in terms of their efficiency. This part of the EN 1822 series deals with measuring the efficiency of filter elements, specifying the conditions and procedures for carrying out tests, describing a specimen test apparatus and its components, and including the method for evaluating test results.

This European Standard applies to efficient particulate air filters (EPA), high efficiency particulate air filters (HEPA) and ultra low penetration air filters (ULPA) used in the field of ventilation and air conditioning and for technical processes, e.g. for applications in clean room technology or pharmaceutical industry. It establishes a procedure for the determination of the efficiency on the basis of a particle counting method using a liquid test aerosol, and allows a standardized classification of these filters in terms of their efficiency. This part of the EN 1822 series deals with measuring the efficiency of filter elements, specifying the conditions and procedures for carrying out tests, describing a specimen test apparatus and its components, and including the method for evaluating test results.

EN 1822-5:2009 is classified under the following ICS (International Classification for Standards) categories: 13.040.40 - Stationary source emissions; 23.120 - Ventilators. Fans. Air-conditioners. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1822-5:2009 has the following relationships with other standards: It is inter standard links to EN 1822-5:2000, EN ISO 29463-5:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase EN 1822-5:2009 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Schwebstofffilter (EPA, HEPA und ULPA) - Teil 5: Abscheidegradprüfung des FilterelementsFiltres à air à haute efficacité (EPA, HEPA et ULPA) - Partie 5: Mesure de l'efficacité de l'élément filtrantHigh efficiency air filters (EPA, HEPA and ULPA) - Part 5: Determining the efficiency of filter elements23.120QDSUDYHVentilators. Fans. Air-conditionersICS:Ta slovenski standard je istoveten z:EN 1822-5:2009SIST EN 1822-5:2010en01-januar-2010SIST EN 1822-5:2010SLOVENSKI

STANDARDSIST EN 1822-5:20011DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1822-5

November 2009 ICS 13.040.40 Supersedes EN 1822-5:2000English Version

High efficiency air filters (EPA, HEPA and ULPA) - Part 5: Determining the efficiency of filter elements

Filtres à air à haute efficacité (EPA, HEPA et ULPA) - Partie 5: Mesure de l'efficacité de l'élément filtrant

Schwebstofffilter (EPA, HEPA und ULPA) - Teil 5: Abscheidegradprüfung des Filterelements This European Standard was approved by CEN on 17 October 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1822-5:2009: ESIST EN 1822-5:2010

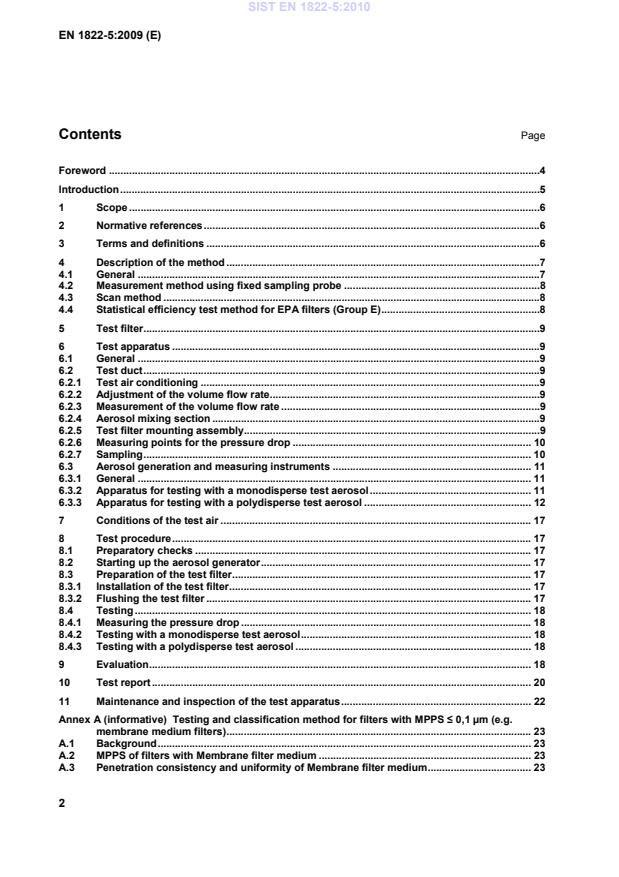

Page Foreword .4Introduction .51Scope .62Normative references .63Terms and definitions .64Description of the method .74.1General .74.2Measurement method using fixed sampling probe .84.3Scan method .84.4Statistical efficiency test method for EPA filters (Group E) .85Test filter .96Test apparatus .96.1General .96.2Test duct .96.2.1Test air conditioning .96.2.2Adjustment of the volume flow rate .96.2.3Measurement of the volume flow rate .96.2.4Aerosol mixing section .96.2.5Test filter mounting assembly .96.2.6Measuring points for the pressure drop . 106.2.7Sampling . 106.3Aerosol generation and measuring instruments . 116.3.1General . 116.3.2Apparatus for testing with a monodisperse test aerosol . 116.3.3Apparatus for testing with a polydisperse test aerosol . 127Conditions of the test air . 178Test procedure . 178.1Preparatory checks . 178.2Starting up the aerosol generator . 178.3Preparation of the test filter . 178.3.1Installation of the test filter . 178.3.2Flushing the test filter . 178.4Testing . 188.4.1Measuring the pressure drop . 188.4.2Testing with a monodisperse test aerosol . 188.4.3Testing with a polydisperse test aerosol . 189Evaluation . 1810Test report . 2011Maintenance and inspection of the test apparatus . 22Annex A (informative)

Testing and classification method for filters with MPPS ≤ 0,1 µm (e.g. membrane medium filters) . 23A.1Background . 23A.2MPPS of filters with Membrane filter medium . 23A.3Penetration consistency and uniformity of Membrane filter medium . 23SIST EN 1822-5:2010

Testing and classification of filters using media with (charged) synthetic fibers . 26B.1Background . 26B.2Scope . 26B.3Procedure for testing and classification of HEPA and ULPA filters using media with (charged) synthetic fibres . 26B.4Publication of data and labelling of products for HEPA and ULPA filters using media with (charged) synthetic fibres . 27Bibliography . 28 SIST EN 1822-5:2010

3.1 sampling duration time during which the particles in the sampling volume flow are counted (upstream or downstream) 3.2 measuring procedure with fixed sampling probes determination of the integral efficiency using fixed sampling probes upstream and downstream of the test filter SIST EN 1822-5:2010

A record of the filter data according to Clause 10 is required in the form of a type test certificate or alternatively a factory test certificate. However, the supplier shall be able to provide documentary evidence to verify the published filter data upon request. This can be done by either: maintaining a certified quality management system (e.g. EN ISO 9000), which forces him to apply statistically based methods for testing and documenting efficiency for all EPA filters as per EN 1822 (all parts); or using accepted statistical methods to test all of his production lots of EPA filters. Either the “skip lot procedure” as described in ISO 2859-1 may be used or any equivalent alternative method. NOTE This “skip lot procedure” as described in ISO 2859-1 implies that, at the beginning, the test frequency is high and is in the course of further testing reduced as the production experience grows and the products produced are conform to the target. As an example: the first eight production lots, 100 % of the produced filters are tested. If all the tests are positive, the frequency is reduced to half for the next eight production lots. If all the tests are positive again it is reduced to half again, and so on until only one out of eight lots has to be tested (= minimum test frequency). Each time, one of the tested filters fails; the test frequency is doubled again. In any case the number of samples tested per lot should be more than three filters. SIST EN 1822-5:2010

Key 1 Coarse dust filter 2 Fine dust filte 3 Fan 4 Air heating 5 High efficiency air filter 6 Aerosol inlet to the test duct 7 Temperature measurement 8 Hygrometer 9 Sampler, particle size analysis 10 Sampler, upstream 11 Ring pipe for differential pressure measurement 12 Manometer 13 Test filter mounting assembly 14 Measuring damper in accordance with

EN ISO 5167-1 15 Measurement of absolute pressure 16 Manometer measuring differential pressure 17 Sampler, downstream Figure 1 — Example of a test rig 6.2.6 Measuring points for the pressure drop The measuring points for pressure drop shall be so arranged that the mean value of the static pressure in the flow upstream and downstream of the filter can be measured. The planes of the pressure measurements upstream and downstream shall be positioned in regions of an even flow with a uniform flow profile. In rectangular or square test ducts, smooth holes with a diameter of 1 mm to 2 mm for the pressure measurements shall be bored in the middle of the channel walls, normal to the direction of flow. The four holes shall be interconnected with a circular pipe. 6.2.7 Sampling In order to determine the efficiency, partial flows are extracted from the test volume flow by sampling probes and led to the particle counters. The diameter of the probes shall be chosen so that isokinetic conditions pertain in the duct at the given volume flow rate for the sample. In this way sampling errors can be neglected due to the small size of the particles in the test aerosol. The connections to the particle counter shall be as short as possible. Samples on the upstream side are taken by a fixed sampling probe SIST EN 1822-5:2010

The number distribution concentration of the test aerosol can be determined using a suitable particle size analysis system (e.g. a differential mobility particle sizer - DMPS) or with a laser particle counter suitable for these test purposes. The limit error of the measurement method used to determine the number median value shall not exceed ± 20 % (relative to the measurement value). The number of counted particles measured upstream and downstream shall be sufficiently large to provide statistically meaningful results, without the concentration exceeding the measuring range of the upstream particle counter. If the upstream number concentration exceeds the range of the particle counter (in the counting mode), a dilution system shall be inserted between the sampling point and the counter. The particle counting can be carried out using either a pair of counters operating in parallel on the upstream and downstream sides, or using a single counter to measure the number concentrations on the upstream and downstream sides alternately. If measurements are made with

...

The EN 1822-5:2009 standard provides a comprehensive framework for evaluating the efficiency of high efficiency air filters, including EPA, HEPA, and ULPA filters. Its scope is particularly relevant for industries requiring stringent air quality control, including ventilation, air conditioning, clean room technology, and the pharmaceutical sector. The standard sets forth a robust procedure for determining filter efficiency through a particle counting method that utilizes a liquid test aerosol, ensuring accuracy and consistency in results. One of the key strengths of EN 1822-5:2009 lies in its detailed methodology, which includes precise conditions and procedures for testing filter elements. This specificity not only aids in the reliability of test outcomes but also supports the standardized classification of air filters according to their efficiency levels. By defining the parameters for a specimen test apparatus and describing its components, this standard enhances the reproducibility of tests across different laboratories and applications. Moreover, the relevance of this standard expands beyond mere compliance; it plays a crucial role in ensuring that air filtration systems meet the necessary performance criteria for health and safety, particularly in critical environments where air purity is paramount. The structured evaluation process outlined in EN 1822-5:2009 serves to guide manufacturers and users alike in achieving optimal filtration solutions, thereby contributing to improved air quality and operational efficiency. In summary, the EN 1822-5:2009 standard not only sets a high benchmark for the assessment of air filter efficiency but also underscores the importance of standardized testing procedures in advancing technologies and practices across various critical industries.

SIST EN 1822-5:2010に関する詳細なレビューは以下の通りです。 この標準は、微小粒子空気フィルター(EPA)、高効率微小粒子空気フィルター(HEPA)、そして超低遷移空気フィルター(ULPA)に適用され、特に換気及び空調分野での利用に重点を置いています。さらに、クリーンルーム技術や製薬業界など特定の技術プロセスでの応用に役立ちます。このように、幅広い分野におけるフィルターの効率を測定するための基盤を提供している点が大きな強みです。 EN 1822-5:2009は、フィルターの効率を定量的に評価するためのプロセスを確立しています。具体的には、液体テストエアロゾルを用いた粒子計測方法による効率の算定を行います。この方法により、フィルターの効率を標準化した形で分類することが可能となり、業界全体での適用性と一致性を実現しています。 さらに、この標準はフィルター要素の効率測定に関連する条件や手続きを具体的に定めています。また、試験用の装置とその構成要素についても詳細に説明されており、試験結果の評価方法も含まれています。この規格に基づく試験方法は、フィルターの性能評価において高い信頼性と一貫性を保証します。 全体的に、EN 1822-5:2009は、高効率微小粒子空気フィルターの技術的な利点を最大化するための計測手法を整備しており、様々な業界での実用性が高いことから、非常に関連性のある標準であると言えます。

SIST EN 1822-5:2010 표준은 고효율 공기 필터(EPA, HEPA 및 ULPA)의 효율성을 평가하는데 필수적인 지침을 제시합니다. 이 표준의 범위는 환기 및 공조 분야, 청정실 기술이나 제약 산업과 같은 기술적 프로세스에서 사용되는 고효율 입자 공기 필터의 효율성을 측정하는 데 초점을 맞추고 있습니다. 이는 공기 필터의 성능을 보다 효과적으로 관리하기 위해 설계되었습니다. 이 표준의 강점 중 하나는 액체 테스트 에어로솔을 사용하여 입자 계수 방법에 기반한 효율성 측정 절차를 확립하는 것입니다. 이러한 접근은 테스트 결과의 신뢰성을 높이며 공기 필터의 성능을 정량적으로 평가할 수 있는 방법을 제공합니다. 따라서, SIST EN 1822-5:2010 표준은 필터 요소의 효율성을 평가하기 위한 조건과 절차를 명확히 하고, 시료 테스트 장치 및 그 구성 요소에 대한 설명을 포함하고 있습니다. 이 표준은 필터의 효율성을 통해 환경 및 건강 안전성을 보장하는 데 매우 중요한 역할을 하며, 고성능 필터를 사용할 수 있는 명확한 기준을 제시하여 산업 전반에 걸쳐 고품질의 공기 정화를 위한 기반을 마련합니다. 따라서, EN 1822-5:2009 표준은 다양한 산업 분야에서의 적용 가능성 및 중요성을 바탕으로 고효율 공기 필터의 효율성을 표준화할 수 있는 중요한 도구로 자리매김하고 있습니다.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...