EN 17558:2023

(Main)Ergonomics - Ergonomics of PPE ensembles

Ergonomics - Ergonomics of PPE ensembles

This document contains test methods for comparing the performance of different ensembles as part of any PPE selection process.

This document does not replace the product standards for the certification of individual items of PPE. It specifies the testing of individual items of PPE as an ensemble, so that the interactions between the individual items of PPE can be evaluated and any adverse interactions between the individual items of PPE, the user and the environment can be identified.

It specifies requirements for testing by either assessing the performance of a PPE ensemble against a benchmark condition (i.e. benchmark testing) or assessing the performance of two or more PPE ensembles against each other (i.e. comparative testing).

This document incorporates examples of laboratory and field tests. It can also be used to assess the performance regarding the ergonomics of an ensemble that incorporates an item of PPE that has never before been incorporated into an ensemble, and the listed methods can be combined into dedicated test batteries for evaluating that ensemble.

Ergonomie - Ergonomie von PSA-Ensembles

Dieses Dokument enthält Prüfverfahren zum Vergleich der Leistungsfähigkeit verschiedener Ensembles als Teil eines PSA-Auswahlverfahrens.

Dieses Dokument ersetzt nicht die Produktnormen für die Zertifizierung einzelner PSA-Produkte. Es legt die Prüfung einzelner PSA-Produkte als Ensemble fest, damit die Wechselwirkung zwischen den einzelnen PSA-Produkten bewertet und nachteilige Wechselwirkungen zwischen den einzelnen PSA-Produkten, dem Anwender und der Umgebung erkannt werden können.

Es legt die Anforderungen an die Prüfung entweder durch die Bewertung der Leistung eines PSA-Ensembles im Vergleich zu einer Referenzbedingung (d. h. Benchmark-Prüfung) oder durch die Bewertung der Leistungsfähigkeit von zwei oder mehr PSA-Ensembles im Vergleich zueinander (d. h. Vergleichsprüfung) fest.

Dieses Dokument enthält Beispiele für Labor- und Feldprüfungen. Es kann außerdem zur Bewertung der Leistung in Bezug auf die Ergonomie des Ensembles verwendet werden, das ein PSA-Produkt umfasst, das zuvor noch nie in ein Ensemble integriert wurde, und die aufgeführten Methoden können zu speziellen Prüfreihen für die Bewertung dieses Ensembles kombiniert werden.

Ergonomie - Ergonomie des ensembles d’EPI

Le présent document contient des méthodes d’essai pour la comparaison des performances de différents ensembles dans le cadre de tout processus de sélection d’EPI.

Le présent document ne remplace pas les normes de produits pour la certification des éléments d’EPI individuels. Il spécifie l’essai des éléments d’EPI individuels en tant qu’ensemble, afin de pouvoir évaluer les interactions entre les éléments d’EPI individuels et identifier toute interaction négative entre les différents éléments d’EPI, l’utilisateur et l’environnement.

Il spécifie les exigences en matière d’essais, soit en évaluant les performances d’un ensemble d’EPI par rapport à une condition de référence (c’est-à-dire un essai de référence), soit en évaluant les performances de deux ensembles d’EPI ou plus les uns par rapport aux autres (c’est-à-dire un essai comparatif).

Le présent document comprend des exemples d’essais en laboratoire et sur le terrain. Il peut également être utilisé pour évaluer les performances en matière d’ergonomie d’un ensemble qui comprend un élément d’EPI n’ayant jamais été intégré auparavant dans un ensemble et les méthodes répertoriées peuvent être combinées pour former des séries d’essais visant à évaluer cet ensemble.

Ergonomija - Ergonomija kompletov osebne varovalne opreme (OVO)

Ta dokument je mogoče uporabiti za primerjavo zmogljivosti različnih kompletov v okviru katerega koli postopka izbire osebne varovalne opreme (OVO).

Ta dokument ne nadomešča standardov za izdelke v zvezi s certificiranjem posameznih elementov osebne varovalne opreme. Določa preskušanje posameznih elementov osebne varovalne opreme kot celote, tako da je mogoče ovrednotiti interakcijo med posameznimi elementi osebne varovalne opreme in ugotoviti morebitne škodljive interakcije med njimi.

Določa zahteve za preskušanje bodisi z ocenjevanjem učinkovitosti kompleta osebne varovalne opreme glede na referenčni pogoj (tj. referenčno preskušanje) ali z ocenjevanjem učinkovitosti dveh ali več kompletov osebne varovalne opreme med seboj (tj. primerjalno preskušanje).

Standard zajema tako laboratorijsko kot terensko preskušanje. Uporabiti ga je mogoče tudi za ocenjevanje učinkovitosti v zvezi z ergonomijo kompleta, ki vključuje element osebne varovalne opreme, ki še nikoli doslej ni bil vključen v komplet.

General Information

- Status

- Published

- Publication Date

- 27-Jun-2023

- Technical Committee

- CEN/TC 122 - Ergonomics

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 28-Jun-2023

- Due Date

- 27-Jun-2022

- Completion Date

- 28-Jun-2023

Overview

EN 17558:2023 (CEN) - "Ergonomics - Ergonomics of PPE ensembles" defines standardized test methods to evaluate the ergonomic performance of complete personal protective equipment (PPE) ensembles. It is intended for use in PPE selection and evaluation processes and focuses on testing interactions between individual PPE items, the wearer and the environment. This standard complements - but does not replace - product standards for individual PPE certification.

Key topics and requirements

- Scope and purpose

- Compares whole PPE ensembles rather than single items to identify adverse interactions and ergonomic impacts.

- Supports both benchmark testing (against a minimal-clothing reference condition) and comparative testing (ensemble vs ensemble).

- Test methods

- Includes laboratory and field test examples; methods can be combined into bespoke test batteries for specific ensembles.

- Tests use human test persons (selection criteria, withdrawal rules) and recommend balanced repeated-measures designs and statistical analysis (see Annex A).

- Functional performance areas

- Mobility - restriction of movement and task performance.

- Vision - normal and total field of view.

- Manual dexterity - ability to perform fine manipulations while wearing ensemble.

- Hearing ability - speech and auditory perception with hearing PPE/ESE.

- Thermal impact - physiological and comfort effects of thermal strain.

- Overall preference - subjective comparative ratings in usability testing.

- Practical performance tests

- Simulated or real work tasks under expected use conditions (lighting, noise, temperature).

- Reporting and expertise

- Test reports must document ensemble composition and results (Clause 10).

- Ergonomic interpretation by trained ergonomists or qualified safety professionals is recommended.

- Annexes

- Provide experimental design, test preparations, movement/vision/manual dexterity/hearing/thermal protocols, use of manikins or virtual models, and example test batteries.

Applications and who uses it

- Manufacturers - design and validate PPE ensembles, identify adverse interactions between components (including smart PPE/ESE).

- Procurement and purchasing teams - compare ensembles for purchase decisions and tender specifications.

- Employers and safety managers - select ergonomic PPE to improve worker compliance and reduce performance hindrance, and demonstrate due diligence under legislation (e.g., EU Regulation 2016/425).

- Test laboratories and ergonomists - implement standardized protocols for ensemble testing and reporting.

- Emergency services and industrial users - evaluate ensembles for police, firefighters, rescue teams, and specialized industrial teams.

Related standards

- EN 13921 (principles of PPE ergonomics)

- Normative references cited in EN 17558: EN 352 (hearing protectors), EN ISO 7731, EN ISO 9886, EN ISO 9921, EN ISO 11904-1, EN ISO 12894, EN 13819-2

EN 17558:2023 is a practical, modular standard enabling consistent ergonomics evaluation of PPE ensembles to support safer, more usable protective systems.

Frequently Asked Questions

EN 17558:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "Ergonomics - Ergonomics of PPE ensembles". This standard covers: This document contains test methods for comparing the performance of different ensembles as part of any PPE selection process. This document does not replace the product standards for the certification of individual items of PPE. It specifies the testing of individual items of PPE as an ensemble, so that the interactions between the individual items of PPE can be evaluated and any adverse interactions between the individual items of PPE, the user and the environment can be identified. It specifies requirements for testing by either assessing the performance of a PPE ensemble against a benchmark condition (i.e. benchmark testing) or assessing the performance of two or more PPE ensembles against each other (i.e. comparative testing). This document incorporates examples of laboratory and field tests. It can also be used to assess the performance regarding the ergonomics of an ensemble that incorporates an item of PPE that has never before been incorporated into an ensemble, and the listed methods can be combined into dedicated test batteries for evaluating that ensemble.

This document contains test methods for comparing the performance of different ensembles as part of any PPE selection process. This document does not replace the product standards for the certification of individual items of PPE. It specifies the testing of individual items of PPE as an ensemble, so that the interactions between the individual items of PPE can be evaluated and any adverse interactions between the individual items of PPE, the user and the environment can be identified. It specifies requirements for testing by either assessing the performance of a PPE ensemble against a benchmark condition (i.e. benchmark testing) or assessing the performance of two or more PPE ensembles against each other (i.e. comparative testing). This document incorporates examples of laboratory and field tests. It can also be used to assess the performance regarding the ergonomics of an ensemble that incorporates an item of PPE that has never before been incorporated into an ensemble, and the listed methods can be combined into dedicated test batteries for evaluating that ensemble.

EN 17558:2023 is classified under the following ICS (International Classification for Standards) categories: 13.180 - Ergonomics; 13.340.01 - Protective equipment in general. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase EN 17558:2023 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2024

Ergonomija - Ergonomija kompletov osebne varovalne opreme (OVO)

Ergonomics - Ergonomics of PPE ensembles

Ergonomie - Ergonomie von PSA-Ensembles

Ergonomie - Ergonomie des ensembles d’EPI

Ta slovenski standard je istoveten z: EN 17558:2023

ICS:

13.180 Ergonomija Ergonomics

13.340.01 Varovalna oprema na Protective equipment in

splošno general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17558

EUROPEAN STANDARD

NORME EUROPÉENNE

June 2023

EUROPÄISCHE NORM

ICS 13.180; 13.340.01

English Version

Ergonomics - Ergonomics of PPE ensembles

Ergonomie - Ergonomie des ensembles d'EPI Ergonomie - Ergonomie von PSA-Ensembles

This European Standard was approved by CEN on 21 May 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17558:2023 E

worldwide for CEN national Members.

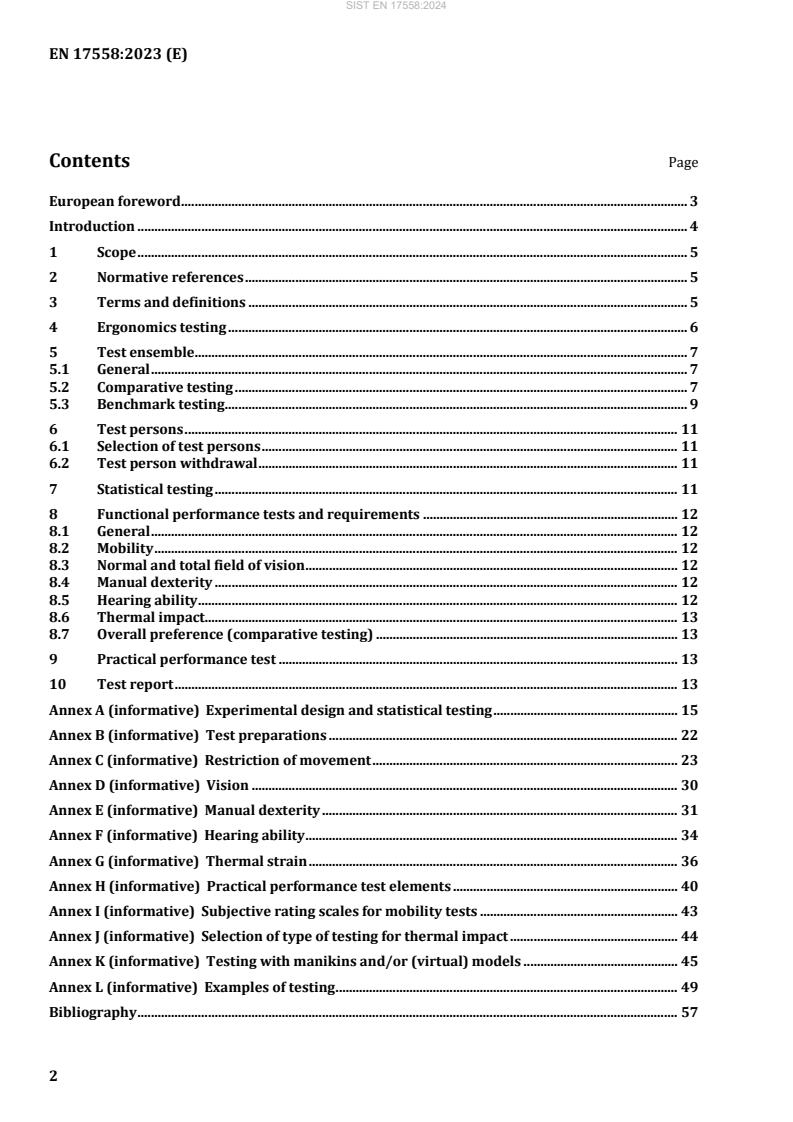

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Ergonomics testing . 6

5 Test ensemble . 7

5.1 General . 7

5.2 Comparative testing . 7

5.3 Benchmark testing . 9

6 Test persons . 11

6.1 Selection of test persons . 11

6.2 Test person withdrawal . 11

7 Statistical testing . 11

8 Functional performance tests and requirements . 12

8.1 General . 12

8.2 Mobility . 12

8.3 Normal and total field of vision . 12

8.4 Manual dexterity . 12

8.5 Hearing ability . 12

8.6 Thermal impact. 13

8.7 Overall preference (comparative testing) . 13

9 Practical performance test . 13

10 Test report . 13

Annex A (informative) Experimental design and statistical testing . 15

Annex B (informative) Test preparations . 22

Annex C (informative) Restriction of movement . 23

Annex D (informative) Vision . 30

Annex E (informative) Manual dexterity . 31

Annex F (informative) Hearing ability . 34

Annex G (informative) Thermal strain . 36

Annex H (informative) Practical performance test elements . 40

Annex I (informative) Subjective rating scales for mobility tests . 43

Annex J (informative) Selection of type of testing for thermal impact . 44

Annex K (informative) Testing with manikins and/or (virtual) models . 45

Annex L (informative) Examples of testing . 49

Bibliography . 57

European foreword

This document (EN 17558:2023) has been prepared by Technical Committee CEN/TC 122 “Ergonomics”,

the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by December 2023, and conflicting national standards shall

be withdrawn at the latest by December 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

It has long been recognized that personal protective equipment (PPE) can have unwanted side-effects on

the wearer in terms of imposing additional physical workload, hindering movement, impairing sensory

perception or in some cases causing considerable discomfort. Such side effects can reduce the efficiency

of task performance and/or encourage the user not to wear the PPE or use the PPE incorrectly thereby

impairing the level of protection afforded. This problem has been recognized in legislation. The

Regulation (EU) 2016/425 of the European Parliament and of the Council of 9 March 2016 on personal

protective equipment [18] places duties on PPE manufacturers to take account of ergonomic

requirements and assists employers in demonstrating compliance with national legislation, whilst the

associated EC Directive on the use by workers of personal protective equipment at the workplace

(89/656/EEC) [19] places similar duties on employers providing PPE for use. These latter requirements

have been transposed into national legislation in all Member States.

This document can be used to compare the performance of different ensembles as part of any PPE

selection process, thereby again assisting employers in evaluating PPE Ensembles in standardized

conditions.

To facilitate compliance with legislation, European technical product standards for individual items of

PPE are gradually introducing tests for ergonomic characteristics. However, these standards are mainly

for testing individual products and seldom include the assessment of interactions with other items of PPE

except in isolated cases (e.g. helmet-mounted ear-muffs conforming to EN 352-3) where they are an

essential element of their use. An exception as an example is ISO/TS 11999-2, which details a series of

tests aimed at evaluating the compatibility of the different components of the PPE ensembles used by

firefighters.

Some PPE items or ensembles incorporate Electronic Safety Equipment forming a smart system designed

to enhance the protection provided. Such systems are included if they form a discrete wearable item or

their integration is considered to possibly have an influence on the ergonomic impact of the ensemble on

the wearer. For example, interconnections or integrated elements might have an adverse effect on the

mobility of a wearer.

This document has therefore been prepared to enable PPE ensembles, such as those worn by police,

firefighters and other emergency services, as well as some industrial users; to be evaluated and

objectively assessed for ergonomic performance as complete ensembles, rather than in their component

parts. As such it will provide a valuable tool to aid manufacturers and purchasers of PPE to make informed

decisions in selecting and designing those ensembles and creating awareness of interaction issues

between PPE items. Test and evaluation of PPE ensembles and systems (efficiency and ergonomics)

should be carried out by those who create the ensemble. The wide range of methods described in the

annexes may be used as specific test packages or handpicked and combined into dedicated test batteries

to match the intended purpose of a particular PPE ensemble.

Some of the tests can also be suitable for adoption as part of product standards for individual items of

PPE or they can refer to this document, although that is not their main purpose.

The principles relating to the ergonomics of PPE are presented in EN 13921. This document builds on

those principles and provides appropriate tests to verify that an ensemble meets those principles.

1 Scope

This document contains test methods for comparing the performance of different ensembles as part of

any PPE selection process.

This document does not replace the product standards for the certification of individual items of PPE. It

specifies the testing of individual items of PPE as an ensemble, so that the interactions between the

individual items of PPE can be evaluated and any adverse interactions between the individual items of

PPE, the user and the environment can be identified.

It specifies requirements for testing by either assessing the performance of a PPE ensemble against a

benchmark condition (i.e. benchmark testing) or assessing the performance of two or more PPE

ensembles against each other (i.e. comparative testing).

This document incorporates examples of laboratory and field tests. It can also be used to assess the

performance regarding the ergonomics of an ensemble that incorporates an item of PPE that has never

before been incorporated into an ensemble, and the listed methods can be combined into dedicated test

batteries for evaluating that ensemble.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 352 (all parts), Hearing protectors

EN 458, Hearing protectors - Recommendations for selection, use, care and maintenance - Guidance

document

EN 13819-2, Hearing protectors - Testing - Part 2: Acoustic test methods

EN ISO 7731, Ergonomics - Danger signals for public and work areas - Auditory danger signals (ISO 7731)

EN ISO 9886, Ergonomics - Evaluation of thermal strain by physiological measurements (ISO 9886)

EN ISO 9921, Ergonomics - Assessment of speech communication (ISO 9921)

EN ISO 11904-1, Acoustics - Determination of sound immission from sound sources placed close to the ear -

Part 1: Technique using a microphone in a real ear (MIRE technique) (ISO 11904-1)

EN ISO 12894, Ergonomics of the thermal environment - Medical supervision of individuals exposed to

extreme hot or cold environments (ISO 12894)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

benchmark condition

condition at which a test person is wearing non-restrictive, minimal, light clothing such as shorts and a

cotton t-shirt and light, flexible footwear such as trainers or plimsolls

Note 1 to entry: Benchmark testing for thermal impact in accordance with Annex G might require the use of an

alternative benchmark condition.

3.2

benchmark testing

testing for assessing the performance of an ensemble against the benchmark condition

3.3

comparative testing

testing for assessing the performance of two or more ensembles against each other

3.4

electronic safety equipment

ESE

products that contain electronics embedded in or associated with the product for use by wearers that

provides enhanced safety functions for wearers during operations in a use environment

3.5

functional performance test

procedure testing specified functionalities with wearers of PPE ensembles under specified conditions

3.6

PPE ensemble

collection of items of personal protective equipment worn by an individual

3.7

practical performance test

test procedure with wearers of PPE ensembles under simulated or real work tasks and if relevant then

also under expected use conditions

3.8

use conditions

conditions under which different items of PPE normally are used by the wearer

3.9

smart PPE

PPE that uses ESE (electronic safety equipment) or material solutions that interact actively, by

responding or adapting to environmental changes or react according to external signal input

4 Ergonomics testing

Ergonomics of PPE can be tested by use of either test persons, use of manikins and/or use of (computer)

models. This document is dealing only with testing of the ergonomics of PPE with test persons.

NOTE The General Data Protection Regulation, Directive 95/46/EC and ethical aspects of human testing and

the Helsinki Declaration are applicable to any tests with test persons.

Information about alternative testing, e.g. with a manikin and/or (virtual) models, is available in Annex K.

A representative sample of target users shall be selected for relevant ergonomics evaluation (see Annex A

for details). A balanced repeated measurement design shall be used for both the benchmark and

comparative testing of ensembles to ensure that the order of experimentation does not influence the test

results (Annex A).

Depending on the required level of complexity the tasks may consist of individual postures. Ergonomic

analysis of tasks under use conditions is recommended before selecting specific tests in order to

guarantee that all major potential constraints are covered. Testing may be done in either controlled

laboratory conditions or field settings resembling expected use conditions, e.g. environmental

parameters, such as heat, cold, poor lighting, noise, etc.

It is strongly recommended that a person who has been trained in ergonomics, e.g. health and safety

expert, ergonomist, work hygienist, should interpret the test results. It is often a person who has been

certified for that qualification, but may also be a person who has a long (documented) experience in the

field of ergonomics, e.g. publications, documented earlier evaluations, etc.

5 Test ensemble

5.1 General

All the items of a test ensemble shall be worn by the test person during testing in accordance with the

instructions of the manufacturer. A complete description of a test ensemble shall be recorded in a test

report conforming to Clause 10.

Although items of clothing being worn with the ensemble might not be classified as PPE, they may

influence ensemble performance. For example, clothing worn beneath protective clothing may influence

heat exchange and consequently thermal comfort or safety. Similarly, tight fitting or bulky garments may

influence mobility. Any description of a test ensemble shall therefore include all clothing layers, footwear,

hand wear and headwear (including helmets, hearing protection, communications systems and

respiratory protection) including the non-PPE items.

All testing shall either be conducted:

a) to compare two or more PPE ensembles (with comparable protective functions), i.e. comparative

testing in accordance with 5.2; or

b) in an absolute comparison against an unrestricted benchmark condition, i.e. benchmark testing in

accordance with 5.3.

5.2 Comparative testing

Where some items of an ensemble are being replaced, and undergoing assessment by comparative

testing, other components of the existing ensemble need not be new. The status (new or used) of all items

forming the ensemble shall be documented in the test report conforming to Clause 10.

Where all the items of an ensemble are undergoing assessment by comparative testing, each ensemble

shall be subjected to the relevant tests specified in Clause 8.

Where only a selection of items of an ensemble is being tested, each ensemble shall be subjected to testing

specified in Clause 8, however, if it may be reasonably assumed that the items of PPE undergoing testing

have no influence on a particular test parameter specified in Clause 8, then it is not necessary to conduct

the test for that parameter. Table 1 shows which tests from Clause 8 shall be conducted for a particular

item undergoing assessment.

Table 1 — Parameters from Clause 8 recommended to be assessed for a particular item of PPE undergoing assessment

Item of PPE being Parameters from Clause 8 recommended to be assessed

assessed (part of body

Shoulder/ arm Trunk Hip/knee Clarity Normal Total Manual Hearing Thermal

protected)

mobility 8.2 flexion flexion 8.2 within field field of range of

dexterity 8.5 impact 8.6

8.2 of vision 8.3 vision 8.3 vision 8.3 8.4

Head protection x x x x x x x

Eye protection x x x x x

Respiratory protection x x x x x x x

b

Hearing protection x x x

Clothing x x x x x x x x x

Gloves x x x x

Footwear x x

Fall protection x x x x

Auxiliary heating or x x x x x x

cooling device

a

Smart PPE x x x x x x x x x

NOTE x indicates which parameters from Clause 8 should be assessed for a particular item undergoing assessment.

a

Smart PPE, for example ESE, may be very different and cover various body areas including intra- and intersystem communication means, thus, the assessment parameters

depend on the specific application and need to be chosen individually (see CEN ISO/TR 23383 for reference).

b

Hearing protection may interact with other items (e.g. bulky collar of lifejacket, or a hood) to restrict head movement and therefore total range of vision.

5.3 Benchmark testing

Where all the items of an ensemble are undergoing assessment by benchmark testing, all the items of the

ensemble shall be new and each ensemble shall be subjected to the relevant tests specified in Clause 8.

NOTE For possible pre-treatment options see Annex B.

Where only a selection of the items of an ensemble are undergoing assessment by benchmark testing,

those items being tested and all of those items which potentially impact upon the items being tested shall

be new. Table 2 shows which items shall be new for a particular item undergoing assessment by

benchmark testing. Where used ensembles shall be tested, e.g. for sustainability purposes, the

requirements on items being new in this subclause and Table 2 do not apply.

Where only a selection of items of an ensemble is being tested, each ensemble shall be subjected to testing

specified in Clause 8, however, if it may be reasonably assumed that the items of PPE undergoing

benchmark testing have no influence on a particular test parameter specified in Clause 8, then it is not

necessary to conduct the test for that parameter. Table 1 shows which tests from Clause 8 shall be

conducted for a particular item undergoing assessment by benchmark testing.

Table 2 — Items of PPE required to be new for a particular item undergoing assessment

Item of PPE being Items of PPE required to be new during assessment

assessed

Head Eye Respiratory Hearing Clothing Gloves Footwear Fall Auxiliary Smart

a

protection protection protection protection protection heating or PPE

cooling

Head protection x x x x x x x

Eye protection x x x x x x x

Respiratory x x x x x x x x

protection

Hearing protection x x x x x

Clothing x x x x x x x x

Gloves x x x x x x

Footwear x x x x

Fall protection x x x x x

Auxiliary heating or x x x x x x x x x

cooling device

a

Smart PPE x x x x x x x x x x

NOTE x indicates which items of an ensemble shall be new.

a

Smart PPE may be very different and cover various body areas including intra- and intersystem communication means, thus, the assessment parameters depend on the specific

application and need to be chosen individually (see CEN ISO/TR 23383 for reference).

6 Test persons

6.1 Selection of test persons

The sample of test persons to be used should be established by statistical evaluation taking into account

inter and intra-test person variability and the estimated magnitude of the effect of the combination of

items of PPE on the user. It is recommended that a power analysis is used for this as described in Annex A.

As a practical guideline in any case a minimum of six test persons shall be used to assess an ensemble

against one or more others.

The test persons shall represent the total group of expected wearers reflecting the diversity among this

group. Each test person shall be experienced or appropriately trained in the use of the PPE items’

combinations and shall have passed medical examination (guidance on this is available in EN ISO 12894).

The items of PPE to be evaluated shall be of the appropriate size and correctly fitted for the wearer (see

EN ISO 15537 for support).

If it is not possible to use a representative sample from the user population then the sample used shall

match as closely as possible to the user population (see also A.5 and A.6). For the individual test persons

the most important characteristics are:

— age;

— height;

— body mass;

— gender;

— (self) reported physical fitness;

— skill at the task being simulated.

6.2 Test person withdrawal

Where test persons voluntarily withdraw or are withdrawn from the test battery, results from any

completed activities undertaken shall be included in any assessment of ensemble performance. Where

that withdrawal is for reasons unrelated to the ensembles tested and remaining test persons are still

sufficient to complete the analysis of test results and ensure the required level of statistical significance,

then testing may continue. If not, a new test person shall be recruited as replacement. See also B.5.

If the withdrawal is related to the design of the ensemble it is an important indicator for terminating the

testing and not approving the ensemble. Pass/fail criteria, including the permitted number of ensemble

related drop outs, shall be specified clearly before starting the test (see Clause 8 for ergonomic test

requirements). If a certain number of test persons drop out due to ensemble design factors, then testing

shall be terminated and the ensemble failed. Reasons for withdrawal shall be reported (for reporting

details see Clause 10).

7 Statistical testing

In order to compare ensembles with each other or to a reference ensemble it is essential to look at the

differences in the results (means) in relation to their standard deviation. Differences between the test

ensembles and the benchmark condition or between two or more test ensembles undergoing

comparative testing, shall be compared using statistical tests in order to determine the likelihood of

observed differences being due to chance (see more in Annex A).

The statistical test used shall be stated in the test report conforming to Clause 10.

8 Functional performance tests and requirements

8.1 General

The preparations for the testing specified in 8.2 to 8.7 should conform to Annex B.

Every outcome shall be reported and taken into account in the evaluation.

The criteria to be adopted will be related to the ensemble, the user (population), and the use conditions.

For this, ergonomic relevant critical limits are needed to substantiate ‘appreciable’ effects and shall be

specified. The factors included in this document may need to be combined with other factors depending

on the specific application.

8.2 Mobility

Test mobility in accordance with Annex C.

No visible loss of primary protective function during any of the test movements shall be permitted. If any

separation of protective elements is observed for an ensemble then that ensemble shall be deemed to

have failed.

8.3 Normal and total field of vision

Test field of vision in accordance with Annex D.

For any class of ensemble requiring a reduction in field of vision to achieve satisfactory protective

performance, appropriate evaluative criteria shall be devised and published in the report.

For benchmark testing, unless specific criteria have been identified for any of the individual items of PPE

forming the ensemble, the normal and total field of vision shall be not less than 85 % of that in either axis

in the benchmark condition.

8.4 Manual dexterity

Test manual dexterity in accordance with Annex E.

For benchmark testing, the test ensemble shall not reduce performance in any of the tests by more than

20 % compared to the unencumbered benchmark.

8.5 Hearing ability

Measurement of hearing ability of a PPE ensemble is not required where the ensemble includes a hearing

protector. Where hearing protection is claimed, the sound attenuation methods of EN 13819-2, and

requirements of the product standards (EN 352 series) shall be applicable to the assessment of the

ensemble protective performance. Selection and use of hearing protectors are covered by EN 458.

Test hearing ability in accordance with Annex F.

For benchmark testing, the equivalent continuous sound pressure level (L ) at any octave frequency

eq

band shall differ from the benchmark readings by less than 6 dB.

As described in Annex F, differences in insertion loss at low and high frequencies might reduce speech

intelligibility, particularly if consonants are lost. For applications where speech communication is

regarded as essential, the difference between the sum of low frequency insertion losses (A ) and the

LOW

sum of high frequency insertion losses (A ) shall be minimized and A shall be as low as possible

HIGH HIGH

(Annex F). Where speech intelligibility and/or perception of warning signals are considered critical, the

assessment methods for speech communication (EN ISO 9921) and/or signal recognition (EN ISO 7731)

shall also be applied.

8.6 Thermal impact

Test thermal impact in accordance with Annex G.

For thermal testing the following objective measures shall limit the exposure:

— The heat storage in the body shall be less than 8 J/g body weight.

— Raise or drop in the core temperature shall not be more than 1 °C while the core temperature shall

not increase above 38,5 °C or drop below 35,5 °C.

— Mean skin temperature shall not increase above 40 °C or drop below 25 °C.

— Local skin temperatures shall not raise above 43 or drop below 15 °C.

For benchmark tests at ambient or elevated temperatures test time shall not differ from that wearing the

standard ensemble by more than 10 %.

8.7 Overall preference (comparative testing)

After the test person has performed all tests in 8.2 to 8.6, the person shall be asked to indicate an order

of overall preference for the ensembles tested.

The order of preference and any reasons given for this order shall be recorded in a test report conforming

to Clause 10.

9 Practical performance test

The test shall be carried out in accordance with Annex H.

For benchmark testing all test persons shall successfully complete the proposed elements of a battery of

tests without refusing or being unable to continue. No visible loss of primary protective function during

any of the test movements shall be permitted. If any separation of protective elements is observed for an

ensemble then that ensemble shall be deemed to have failed.

10 Test report

The test report shall provide all information relevant to the selected procedures, the ensemble items

tested and the results obtained. It may be recommended to take photos of the items and how the items

are worn in order to document the test settings and how the PPE ensemble was worn.

The report shall include the following:

a) reference to this test method, i.e. EN 17558:2023, and the specific clauses selected for use.

b) name and address of the test authority, the date of the test, and where the testing was carried out.

c) full details of the ensembles worn, including model numbers and manufacturers, such that the entire

ensemble could be re-assembled if necessary.

d) the number of test persons employed and their gender and other selection characteristics (as

mentioned in 6.1), including the number of test persons withdrawn from the tests.

e) whether the testing was benchmark or comparative.

f) for comparative testing, which items (if any) of the ensembles were not new.

g) for each tested ensemble, any observations and measurements recorded during the tests as specified

in Annex C to Annex F for functional performance testing, and in Annex H for practical performance

testing.

h) for each tested ensemble, any comments from test persons recorded during the tests as required in

Annex C to Annex F for functional performance testing, and in Annex H for practical performance

testing.

i) for each tested ensemble, any apparent failures in protective function or other observations made by

the test administrator as required in Annex C to Annex F for functional performance testing, and in

Annex H for practical performance testing.

j) for benchmark testing, whether or not the ensemble has passed or failed in accordance with the

criteria detailed in Clause 8 or Clause 9, respectively, including the type of statistical test employed

in reaching that conclusion.

k) for any testing, all test results and the type of statistical tests employed.

l) interpretation of the thermal strain testing.

Annex A

(informative)

Experimental design and statistical testing

A.1 General

Basic information on experimental design and statistical testing is given in this Annex. If more advanced

information and support is needed, then the reader is referred to ISO 3494 [33].

A.2 Use of test persons as controls (repeated testing)

To accommodate the effects of variability between individuals, tests involving test persons frequently

make use of experimental designs in which the test persons each undertake the test with each of the

different “treatments” or conditions, thereby serving as their own control group (intra-individual

comparison).

In the present context, different PPE ensembles would form the various conditions. In this way, any effect

on test outcome of differences between test persons is reduced, increasing the chances that any

differences identified between conditions are due to genuine variations between those conditions rather

than being attributable to the test persons taking part.

This convention is adopted in this document.

A.3 Balanced experimental design

In circumstances where there might be some form of sequential or “learning” effect associated with the

performance of any test, experimental designs should be selected which balance out any such effects by

the order in which the test conditions are carried out.

Again, this convention is adopted in this document with a balanced order of any person wearing different

PPE ensembles. It should be noted that this does not remove any learning effect but balances the effect

across the different conditions.

Where two ensembles are to be tested by comparative or benchmark testing a crossover design should

be used, e.g. test persons shall be allocated ensembles so that each ensemble is worn first by half of the

test persons and the test order is randomly selected (balanced experimental design).

In the event of there being three or more ensembles to be compared, a study design may be adopted using

a Latin square [27] with individual test persons being allocated to a wearing order according to the rows

of such squares.

Table A.1 shows the combination of two such squares for six wearers of three ensembles. It will be noted

that this requires each person to carry out the test three times, wearing each of the test ensembles once

and that two test persons will wear each ensemble on any one test occasion. For details on the relevant

procedures also covering larger squares, the user should refer to corresponding textbooks on

experimental design and statistics.

Table A.1 — Latin square design for three ensembles and six test persons

Test person Order of wearing ensembles

1 Ensemble A Ensemble B Ensemble C

2 Ensemble B Ensemble C Ensemble A

3 Ensemble C Ensemble A Ensemble B

4 Ensemble B Ensemble A Ensemble C

5 Ensemble A Ensemble C Ensemble B

6 Ensemble C Ensemble B Ensemble A

A.4 Statistical testing — Number of test persons

At its simplest, two test persons undertaking each of two conditions, with one wearing ensemble A first

and the other wearing ensemble B, would provide a balanced design.

However, one assumption behind any such testing is that the test results do not apply only to those

participating test persons but also to others from the same group or “population” from which the test

persons are drawn. With only two test persons the possibility of a “chance” difference is considerable. To

increase the validity of the assumption, a larger number of test persons are frequently employed, often

with statistical tests of the results.

Statistical testing of the results of any tests under different conditions allows the determination of the

likelihood of a particular outcome being just due to chance variation between those conditions; or

whether there is a genuine difference in their effects. This provides for a greater validity to any findings.

For both comparative (3.3) and benchmark testing (3.2), the user might be interested to show that the

means of ensemble A (μA) and B (μB) are different, i.e. to perform the conventional statistical hypothesis

test (SHT1) for differences with null hypothesis H and alternative hypothesis H :

0 A

H : μ = μ vs. H : μ ≠ μ (SHT1)

0 A B A A B

Alternatively, non-inferiority testing might be preferable in benchmark testing to show that PPE

ensemble A does not perform appreciably worse than benchmark B. For this, an ergonomic relevant non-

inferiority margin (δ), needs to be specified [5] to substantiate ‘appreciable’ effects, as shown in (SHT2):

H : μ ≤ μ – δ vs. H : μ > μ – δ (SHT2)

0 A B A A B

In general, the use of a larger number of test persons increases the likelihood of identifying any genuine

difference between test conditions and reduces the size of any difference which statistical tests are able

to “detect” against background variation. However, the use of large numbers of test persons increases the

complexity of the test process and increases the number of tests required (particularly with each person

carrying out each test condition). Inevitably, this increases the time and cost involved in carrying out the

tests and some form of trade-off or compromise is often necessary.

There are procedures for so-called power calculations to estimate the required sample size for both SHT1

[8] and SHT2 [5] types of hypothesis testing using the paired t-test for the within-subject crossover

design (A.3).

SHT outcomes do not only depend on sample size, but also on many other parameters, such as:

— experimental design (one, two or multiple samples, one or more factors [i.e. influential variables],

ANOVA, regression, survival analysis, …);

— the applied statistical model and test (parametric vs. non-parametric, two- vs one-tailed [cf. SHT1 vs.

SHT2]);

— the type-I-error α (the probability to erroneously accept H when H is true) [with typical values for

A 0

α = 0,05, 0,01, …];

— the type-II-error β (the probability to erroneously accept H when H is true), i.e. power = 1-β

0 A

(probability of rejecting H when it is false, i.e. probability of detecting a ‘significant’ effect) [with

typical values for β = 0,2, 0,05, i.e. power = 0,8, 0,95];

— the surmised effects and variability (often expressed as effect size = mean difference / SD, i.e. in SD

units);

— within-subject correlations; and

— in case of SHT2, on the non-inferiority margin (δ).

When solving for sample size, the user shall supply all those parameters. Relevant input can be found in

specific ergonomics handbooks and standards (e.g. [36]), or deduced from studies providing

experimental or normative data for the test procedures under consideration [4, 24], e.g. for functional

testing of manual dexterity [40, 42, 46].

Key

X effect size Y sample size

trivial effect r = 0,2

small r = 0,4

moderate r = 0,6

large r = 0,8

very large

Figure A.1 — Sample size in relation to effect size and within-subject correlation (r) estimated

for paired t-Tests testing for difference (SHT1, left panel) and non-inferiority (SHT2, right panel)

applying standard assumptions for type-I-error (α = 0,05), type-II-error (β = 0,2, i.e. power = 1-

β = 0,8) and non-inferiority margin (δ = 0,2)

Figure A.1 shows the sample size estimates obtained with specified standard values for the type-I-error

(α = 0,05) and the type-II-error (β = 0,2, i.e. power = 1-β = 0,8), respectively. Within-subject correlation

(r) varied between 0,2 and 0,8 and the mean difference, expressed as effect size ([μA-μB]/SD) with SD

denoting the common or pooled standard deviation, varied between 0 and 4, thus describing trivial to

very large effects according to conventions applied in sports medicine and exercise physiology [25]. The

non-inferiority margin for SHT2 was set to δ = 0,2 in SD units indicating the upper limit to a trivial effect

[25]. The resulting sample size requirements are comparable between SHT1 and SHT2 with slightly lower

numbers for non-inferiority testing, but decreased considerably with increasing effect size and also with

increasing within-subject correlations [3].

Key

X effect size Y type-II-error probability (β)

trivial effect N = 3

small N = 6

moderate N = 8

large β = 20 %

very large β = 5 %

Figure A.2 — Type-II-error β, i.e. the probability to erroneously accept H when H is true, in

0 A

relation to effect size estimated for paired t-Tests with varying sample size (N) and moderate

within-subject correlation (r = 0,6) testing for difference (SHT1, left panel) and non-inferiority

(SHT2, right panel) applying standard assumptions for type-I-error (α = 0,05), and non-

inferiority margin (δ = 0,2)

Plots of the type-II-error β in Figure A.2 suggest that with moderate correlation (r = 0,6) there would be

sufficient power to detect moderate to large effect sizes with N = 8, or large to very large effects with N =

6 when requiring 95 % power (i.e. β = 5 %). They also indicate that the user should avoid ‘pragmatic

approaches’ considering two ensembles as equivalent, if they are not significantly different, as these are

prone to type-II-error (probability of erroneously accepting H ) above 5 % in the presence of modera

...

SIST EN 17558:2024 표준은 개인 보호 장비(PPE) 조합의 인체공학적 특성을 평가하기 위한 시험 방법을 규정하고 있습니다. 이 문서는 PPE 선택 과정의 일환으로 서로 다른 조합의 성능을 비교하는 데 중점을 두고 있으며, 각 개별 PPE 품목의 인증을 위한 제품 표준을 대체하는 것이 아닙니다. 대신, 인체공학적 설계를 고려하여 개별 품목 간의 상호 작용을 평가하고, 사용자 및 환경과의 부정적인 상호 작용을 식별할 수 있도록 돕습니다. 이 표준의 범위는 두 가지 주요 테스트를 포함합니다. 첫째, 기준 조건에 대한 PPE 조합의 성능을 평가하는 기준 테스트(benchmark testing)와 둘째, 서로 다른 두 개 이상의 PPE 조합을 서로 비교하는 비교 테스트(comparative testing)입니다. 이러한 명확한 테스트 방법론은 PPE 조합의 최적화를 위한 신뢰할 수 있는 데이터 생성을 용이하게 합니다. 또한, SIST EN 17558:2024는 실험실 및 현장 테스트의 예시를 포함하고 있어 다양한 조건에서 PPE 조합의 인체공학 성능을 종합적으로 평가할 수 있는 기초 자료를 제공합니다. 특히, 기존의 조합에 포함되지 않았던 새로운 PPE 품목을 포함한 경우에도 해당 조합의 성능을 평가할 수 있는 방법론을 제시합니다. 이는 고유한 조합을 위한 전용 시험 배터리를 구성할 수 있는 가능성을 열어 주어, 다양한 산업 분야에서의 인체공학적 효용성을 강화합니다. 결론적으로, SIST EN 17558:2024 표준은 PPE 조합의 성능 평가를 향상시키는 필수 문서이며, 인체공학 및 안전한 작업 환경을 위한 중요한 기준으로 자리 잡고 있습니다.

Die Norm EN 17558:2023 behandelt die Ergonomie von Persönlicher Schutzausrüstung (PSA) und bietet eine umfassende Grundlage für die Bewertung von PSA-Ensembles. Der Fokus dieser Norm liegt auf den Testmethoden zur Vergleichsbewertung der Leistung verschiedener Ensembles im Rahmen des Auswahlprozesses von PSA. Dies ist besonders wichtig, da die Norm nicht die Produktstandards für die Zertifizierung individueller PSA-Artikel ersetzt, sondern die Interaktionen zwischen den einzelnen Teilen der PSA in einem Ensemble bewertet. Eine der Stärken dieser Norm ist die detaillierte Spezifizierung der Testanforderungen. Sie ermöglicht es, die Leistungsfähigkeit eines PSA-Ensembles sowohl im Vergleich zu einem Referenzzustand (Benchmark-Testing) als auch im Vergleich zu anderen PSA-Ensembles (vergleichendes Testing) zu bewerten. Dadurch wird sichergestellt, dass nicht nur die einzelnen Komponenten, sondern das gesamte Ensemble hinsichtlich seiner ergonomischen Eigenschaften optimiert werden kann. Darüber hinaus beinhaltet die Norm sowohl Labor- als auch Feldtests, was ihre Anwendung und Relevanz in unterschiedlichen praktischen Szenarien erhöht. Besonders hervorzuheben ist die Möglichkeit, die Norm auch auf neue Kombinationen von PSA-Elementen anzuwenden, die bisher noch nicht in Ensembles integriert waren. Die beschriebenen Testmethoden lassen sich zu spezifischen Testbatterien kombinieren, was eine gezielte Bewertung der Ergonomie von neuen Ensembles erleichtert. Zusammenfassend zeigt die EN 17558:2023 durch ihre umfassenden Richtlinien und Testmethoden eine hohe Relevanz für die Gestaltung und Bewertung ergonomischer PSA-Ensembles auf, um sowohl die Benutzerfreundlichkeit als auch die Sicherheit in verschiedenen Einsatzbereichen zu gewährleisten.

The standard EN 17558:2023, titled "Ergonomics - Ergonomics of PPE ensembles," offers a comprehensive framework for evaluating the performance of personal protective equipment (PPE) ensembles through standardized testing methods. Its primary scope revolves around providing relevant procedures for comparing various PPE ensembles during the selection process without replacing the certification standards for individual PPE items. One of the significant strengths of this standard is its emphasis on understanding the interactions among individual items of PPE within an ensemble. This approach allows for the identification of any potential adverse effects that may occur due to the combination of different PPE items, the user, and the surrounding environment. This holistic evaluation is crucial for ensuring the safety and comfort of users in various operational scenarios. Moreover, EN 17558:2023 delineates two fundamental testing methodologies: benchmark testing, which evaluates a PPE ensemble against established conditions, and comparative testing, which allows for direct performance comparisons among multiple PPE ensembles. This versatility aids users in making informed decisions tailored to specific use cases, thereby enhancing the overall effectiveness of PPE selection. The inclusion of both laboratory and field test examples further enriches the standard's practical applicability, offering a robust resource for assessing ergonomic performance. This standard is particularly beneficial for assessing newly integrated PPE items within an ensemble, as it facilitates customized test batteries specific to the user's needs and context. Overall, EN 17558:2023 stands out as a pertinent and necessary document that addresses an often-overlooked aspect of PPE - the ergonomics of ensembles. Its structured approach to testing not only promotes safety and functionality but also underscores the importance of ergonomic considerations in the effective deployment of personal protective equipment.

EN 17558:2023は、個別のPPE(個人用保護具)アイテムの認証基準を置き換えるものではなく、PPE選定プロセスの一環として異なるPPEアンサンブルの性能を比較するテスト方法を提供します。この標準は、PPEアンサンブル内の各アイテム間の相互作用を評価し、ユーザーや環境との間での悪影響を特定するための重要な手段です。 この文書の強みは、PPEアンサンブルの性能を評価するためのベンチマークテストや比較テストに関する要求事項を明確に定義している点にあります。これにより、様々な条件下での性能評価が可能となり、実際の使用環境に即した信頼性の高いデータを提供します。また、ラボテストとフィールドテストの例を取り入れているため、幅広い状況におけるPPEアンサンブルの効果を検証することができます。 さらに、この標準は新たにPPEアイテムがアンサンブルに組み込まれる場合においても、その性能を評価できるように設計されています。これにより、従来のアンサンブルにはない新しい組み合わせの安全性や快適性を評価するための専用テストバッテリーを構築することができます。 EN 17558:2023は、PPEアンサンブルの人間工学に関連する性能を評価するための重要な基準であり、業界全体での適用が期待される標準です。この標準により、PPEの選定プロセスにおける安全性や効果の向上が図られると共に、ユーザーの快適性をも考慮した評価基準が確立されます。

La norme EN 17558:2023 déploie une démarche rigoureuse en matière d'ergonomie des ensembles de protection individuelle (EPI). Son champ d'application se concentre sur l'évaluation comparative des performances des différentes combinaisons d'EPI, ce qui est essentiel dans le cadre du processus de sélection d'EPI. En effet, cette norme permet de tester les interactions entre les différents composants d'un ensemble de protection, garantissant ainsi que les utilisateurs disposent d'une protection optimale sans effets indésirables. Parmi ses forces, la norme se distingue par son approche méthodique qui considère non seulement les performances individuelles des articles, mais aussi leur synergie en tant qu'ensemble. Grâce aux options de tests benchmark et comparatifs, les utilisateurs peuvent évaluer l'efficacité d'un ensemble EPI par rapport à des conditions de référence ou entre plusieurs ensembles, assurant ainsi une sélection éclairée. De plus, l'inclusion de méthodes d'essai en laboratoire et sur le terrain enrichit considérablement son applicabilité. La capacité à évaluer des combinaisons novatrices d'EPI, même celles intégrant des éléments récemment introduits, représente un atout indéniable pour les fabricants et les utilisateurs. Cette flexibilité dans l'évaluation souligne l'importance de la norme EN 17558:2023 non seulement pour la conformité aux standards de sécurité, mais aussi pour l'amélioration continue de l'ergonomie dans la conception des ensembles EPI. En somme, la norme EN 17558:2023 s'avère être un outil précieux pour les professionnels du secteur, offrant une base solide pour l'évaluation des performances ergonomiques des ensembles de protection. Elle est indiscutablement pertinente dans le contexte actuel où la sécurité et le confort des utilisateurs sont primordiaux.

기사 제목: EN 17558:2023 - 인체공학 - PPE 앙상블의 인체공학 기사 내용: 이 문서는 PPE 선택과정의 일부로 다양한 앙상블의 성능을 비교하기 위한 테스트 방법을 포함하고 있습니다. 이 문서는 개별 PPE 제품의 인증을 대체하지 않습니다. 대신, 개별 PPE 항목과 앙상블 간 상호작용을 평가하고 개별 PPE 항목, 사용자 및 환경 간 부정적인 상호작용을 식별하기 위해 개별 PPE 항목의 테스트를 지정합니다. 이 문서는 벤치마크 조건에서 PPE 앙상블의 성능을 평가하거나 두 개 이상의 PPE 앙상블을 서로 비교하여 성능을 평가하는 방식인 비교 테스트를 통해 테스트 요구 사항을 지정합니다. 이 문서에는 실험실 및 현장 테스트의 예시가 포함되어 있습니다. 또한, 앙상블에 이전에 앙상블에 포함되지 않은 PPE 항목이 포함된 앙상블의 인체공학적 성능을 평가하기 위해 사용될 수 있으며, 목록에 나열된 방법은 이러한 앙상블을 평가하기 위한 전용 테스트 배터리로 결합될 수 있습니다.

The article discusses EN 17558:2023, a document that outlines test methods for comparing the performance of different PPE (Personal Protective Equipment) ensembles. It clarifies that the document does not replace product standards for certifying individual items of PPE but focuses on evaluating the interactions between the items of PPE, the user, and the environment. The document specifies requirements for testing, including benchmark testing and comparative testing. It includes examples of laboratory and field tests and can be used to assess the ergonomic performance of ensembles incorporating new PPE items. The listed methods can be combined to create specific test batteries for evaluating these ensembles.

The article discusses the EN 17558:2023 standard on ergonomics of personal protective equipment (PPE) ensembles. The document provides test methods for comparing the performance of different ensembles during the PPE selection process. It is important to note that this standard does not replace the product standards for certifying individual PPE items. Instead, it focuses on testing the interactions between items of PPE within an ensemble, as well as any adverse interactions between the ensemble, the user, and the environment. The standard allows for benchmark testing to assess an ensemble's performance against a benchmark condition, or comparative testing to compare the performance of two or more ensembles. The document includes examples of both laboratory and field tests. Additionally, it can be used to evaluate the ergonomics of an ensemble that incorporates a PPE item that has not been previously tested within an ensemble. The listed methods can be combined into dedicated test batteries for evaluating such ensembles.

記事のタイトル: EN 17558:2023 - 人間工学 - PPEアンサンブルの人間工学 記事内容: この文書には、PPE選択プロセスの一環として、異なるアンサンブルの性能を比較するためのテスト方法が含まれています。 この文書は、個々のPPE製品の認証基準を置き換えるものではありません。代わりに、アンサンブル内の個々のPPEアイテムとの相互作用を評価し、アンサンブルと使用者、環境との悪影響の相互作用を特定するための個々のPPEアイテムのテストを指定します。 この文書では、ベンチマークテストとしてアンサンブルの性能を基準状態と比較する方法、または比較テストとして2つ以上のPPEアンサンブルの性能を比較する方法を指定しています。 この文書には、実験室および現地テストの例も含まれています。さらに、以前にアンサンブル内に組み込まれなかったPPEアイテムを含むアンサンブルの人間工学的性能を評価するために使用することもできます。リストされた方法は、そのようなアンサンブルを評価するための専用のテストバッテリーとして組み合わせることができます。

Article Title: EN 17558:2023 - 人間工学 - PPEアンサンブルの人間工学 Article Content: この文書は、PPE(個人防護具)の選択プロセスの一部として、異なるアンサンブルの性能を比較するためのテスト方法を含んでいます。 この文書は、個別のPPEアイテムの認証のための製品規格の置き換えではありません。ただし、PPEアイテム同士、ユーザー、環境の間の相互作用を評価し、悪影響を及ぼす相互作用を特定するために、PPEアイテムがアンサンブルとしてテストされることを指定しています。 この文書では、ベンチマークテストによるPPEアンサンブルの性能を評価するか、または2つ以上のPPEアンサンブルの性能を比較テストすることで、テスト要件を指定しています。 この文書には、実験室および現地テストの例も含まれています。また、PPEアンサンブルに初めて組み込まれるPPEアイテムの人間工学的性能を評価するために使用することもでき、リストされた方法は、それらのアンサンブルを評価するための専用のテストバッテリーに組み合わせることができます。

기사 제목: EN 17558:2023 - 인간공학 - 개인 보호구조의 인간공학 기사 내용: 이 문서에는 PPE 선택 과정의 일부로 다양한 조합의 성능을 비교하기 위한 시험 방법이 포함되어 있습니다. 이 문서는 개별 PPE 항목의 인증을 위한 제품 표준을 대체하지는 않습니다. 그러나 개별 PPE 항목이 조합으로 테스트되어, 개별 PPE 항목 간의 상호작용이 평가되고, 개별 PPE 항목, 사용자 및 환경 간의 부정적인 상호작용을 식별할 수 있도록 명시합니다. 이 문서는 기준 조건에 대한 PPE 조합의 성능을 평가하는 것을 통해 (기준 테스트) 또는 두 개 이상의 PPE 조합의 성능을 서로 비교하는 것을 통해 (비교 테스팅) 테스트 요구 사항을 명시합니다. 이 문서에는 실험실 및 현장 시험의 예도 포함되어 있습니다. 또한, 이전에 PPE 조합에 포함되지 않은 PPE 항목이 포함된 조합의 인간공학적 성능을 평가하기 위해 사용될 수 있으며, 명시된 방법은 해당 조합을 평가하기 위한 특정한 테스트 배터리로 결합될 수 있습니다.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...