SIST EN ISO 9606-5:2001

(Main)Approval testing of welders - Fusion welding - Part 5: Titanium and titanium alloys, zirconium and zirconium alloys (ISO 9606-5:2000)

Approval testing of welders - Fusion welding - Part 5: Titanium and titanium alloys, zirconium and zirconium alloys (ISO 9606-5:2000)

This standard specifies essential requirements, ranges of approval, test conditions, acceptance requirements and certification for the approval testing of welder performance for the welding of titanium and zirconium. This standard applies to the approval testing of welders for the fusion welding of titanium and zirconium. This standard is intended to provide basis for the mutual recognition by examining bodies for approval relating to welders' competence in the various fields of application.

Prüfung von Schweißern - Schmelzschweißen - Teil 5: Titan und Titanlegierungen, Zirkonium und Zirkoniumlegierungen (ISO 9606-5:2000)

Diese Norm legt die wesentlichen Anforderungen, Geltungsbereiche, Prüf- bedingungen und Bewertungsanforderungen sowie die Prüfungsbescheinigung über die durchgeführte Prüfung des Schweißers für Titan- und Zirkoniumschweißungen fest. Diese Norm ist anzuwenden bei der Prüfung von Schweißern für das Schmelzschweißen von Titan und Zirkonium. Diese Norm ist beabsichtigt, die Grundlage für die gegenseitige Anerkennung von Prüfungen über das Können der Schweißer in den verschiedenen Anwendungsgebieten durch die zuständigen Stellen zu schaffen.

Epreuve de qualification des soudeurs - Soudage par fusion - Partie 5: Titane et ses alliages, zirconium et ses allliages (ISO 9606-5:2000)

La présente norme s'applique à la qualification des soudeurs pour le soudage par fusion du titane et du zirconium.Elle a pour but de fournir les bases d'un système de reconnaissance mutuelle de la qualification des soudeurs délivrée par les organismes d'examen dans les divers domaines d'application. Les épreuves se dérouleront conformément à la présente norme, sauf si des conditions plus sévères sont éventuellement exigées par la norme d'application.Pendant l'épreuve de qualification, il est recommandé de demander au soudeur de faire preuve de son expérience pratique et de sa compétence technologique (examen non obligatoire) portant sur les procédés de soudage, les matériaux et les règles de sécurité applicables à la qualification en cours. L'Annexe A donne des informations sur la partie «Compétence technologique» de l'épreuve.La présente norme est applicable dans le cas où la qualification du soudeur est requise par le client, par l'organisme d'inspection ou par une quelconque instance.Les procédés de soudage concernés par la présente norme sont les procédés de soudage par fusion, manuels ou semi-automatiques, à l'exclusion des procédés totalement mécanisés ou automatiques (voir 5.2).La présente norme concerne la qualification des soudeurs travaillant sur des produits finis ou semi-finis, en matériaux corroyés, forgés ou moulés des types indiqués en 5.4.La délivrance du certificat de qualification relève de la seule responsabilité de l'examinateur ou de l'organisme d'examen.

Preskušanje varilcev - Talilno varjenje - 5. del: Titan in titanove zlitine, cirkonij in cirkonijeve zlitine (ISO 9606-5:2000)

General Information

- Status

- Published

- Publication Date

- 30-Apr-2001

- Technical Committee

- VAR - Welding

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-May-2001

- Due Date

- 01-May-2001

- Completion Date

- 01-May-2001

Relations

- Revised

oSIST prEN ISO 9606:2024 - Qualification testing of welders - Fusion welding (ISO/DIS 9606:2024) - Effective Date

- 01-Nov-2024

Overview

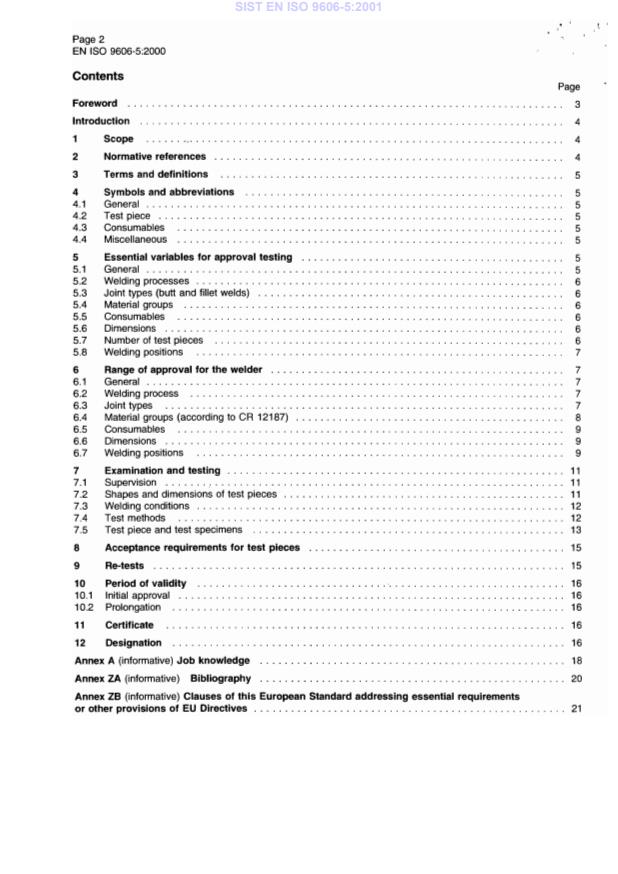

EN ISO 9606-5:2000 - Approval testing of welders - Fusion welding - Part 5 covers the approval (qualification) testing of individual welders who perform fusion welding of titanium and titanium alloys, and zirconium and zirconium alloys. The standard specifies the essential requirements for welder performance assessment, including ranges of approval, test conditions, acceptance requirements and certification. It is intended to support mutual recognition of welder approvals between examining bodies.

Key topics and requirements

- Scope of qualification: Defines the material groups (titanium and zirconium families) and the fusion welding context for which welder performance is assessed.

- Essential requirements: Sets out the competencies and criteria that a welder must demonstrate to gain approval.

- Test conditions: Describes the controlled conditions under which a welder’s practical test is conducted (e.g., welding method, joint type, positions) to ensure repeatable assessment.

- Acceptance criteria: Establishes pass/fail criteria based on visual and destructive/non-destructive examination of test welds.

- Ranges of approval and certification: Explains how the welder’s qualification can be extended (or limited) to other thicknesses, joint types or welding positions and how certification is issued and recognized.

- Mutual recognition: Provides a basis for different examining bodies to accept each other’s approvals, promoting consistency across organizations and borders.

Applications

- Ensures consistent, reliable qualification of welders working with titanium and zirconium, materials commonly used where high strength, corrosion resistance or low-weight are required.

- Applicable in industries such as:

- Aerospace (airframe and engine components)

- Chemical and petrochemical (corrosion-resistant equipment)

- Nuclear (zirconium alloys for certain reactor components)

- Medical devices (titanium implants and instruments)

- Specialized manufacturing and fabrication involving exotic alloys

- Supports procurement, quality assurance and regulatory compliance by providing documented welder competency.

Who should use this standard

- Welding engineers, welding coordinators and fabricators working with titanium/zirconium

- Certification and examining bodies responsible for welder approval

- Quality assurance/inspection personnel and project managers specifying welder competence

- Regulators and clients requiring traceable welder qualifications

Related standards

- Other parts of the ISO 9606 series (welder approval for other base metals)

- Complementary welding procedure and material standards used alongside welder qualification requirements

Keywords: EN ISO 9606-5:2000, approval testing of welders, fusion welding, titanium, titanium alloys, zirconium, zirconium alloys, welder qualification, certification, test conditions, acceptance requirements.

Frequently Asked Questions

SIST EN ISO 9606-5:2001 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Approval testing of welders - Fusion welding - Part 5: Titanium and titanium alloys, zirconium and zirconium alloys (ISO 9606-5:2000)". This standard covers: This standard specifies essential requirements, ranges of approval, test conditions, acceptance requirements and certification for the approval testing of welder performance for the welding of titanium and zirconium. This standard applies to the approval testing of welders for the fusion welding of titanium and zirconium. This standard is intended to provide basis for the mutual recognition by examining bodies for approval relating to welders' competence in the various fields of application.

This standard specifies essential requirements, ranges of approval, test conditions, acceptance requirements and certification for the approval testing of welder performance for the welding of titanium and zirconium. This standard applies to the approval testing of welders for the fusion welding of titanium and zirconium. This standard is intended to provide basis for the mutual recognition by examining bodies for approval relating to welders' competence in the various fields of application.

SIST EN ISO 9606-5:2001 is classified under the following ICS (International Classification for Standards) categories: 03.100.30 - Management of human resources; 25.160.10 - Welding processes; 77.120.50 - Titanium and titanium alloys. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN ISO 9606-5:2001 has the following relationships with other standards: It is inter standard links to oSIST prEN ISO 9606:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN ISO 9606-5:2001 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN ISO 9606-5:2001 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2001

Preskušanje varilcev - Talilno varjenje - 5. del: Titan in titanove zlitine, cirkonij in

cirkonijeve zlitine (ISO 9606-5:2000)

Approval testing of welders - Fusion welding - Part 5: Titanium and titanium alloys,

zirconium and zirconium alloys (ISO 9606-5:2000)

Prüfung von Schweißern - Schmelzschweißen - Teil 5: Titan und Titanlegierungen,

Zirkonium und Zirkoniumlegierungen (ISO 9606-5:2000)

Epreuve de qualification des soudeurs - Soudage par fusion - Partie 5: Titane et ses

alliages, zirconium et ses allliages (ISO 9606-5:2000)

Ta slovenski standard je istoveten z: EN ISO 9606-5:2000

ICS:

03.100.30 Vodenje ljudi Management of human

resources

25.160.10 Varilni postopki in varjenje Welding processes

77.120.50 Titan in titanove zlitine Titanium and titanium alloys

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...