EN 10228-2:2016

(Main)Non-destructive testing of steel forgings - Part 2: Penetrant testing

Non-destructive testing of steel forgings - Part 2: Penetrant testing

This European Standard describes techniques and acceptance criteria to be used for the penetrant testing of steel forgings. The method described is used for the detection of surface discontinuities.

Zerstörungsfreie Prüfung von Schmiedestücken aus Stahl - Teil 2: Eindringprüfung

Diese Europäische Norm legt die Methodik und die Zulässigkeitskriterien fest, die bei der Eindringprüfung von Schmiedestücken aus Stahl anzuwenden sind. Das beschriebene Prüfverfahren dient dem Nachweis von Oberflächenunregelmäßigkeiten.

Essais non destructifs des pièces forgées en acier - Partie 2 : Contrôle par ressuage

Cette norme européenne définit les modalités et les critères d'acceptation pour l’essai par ressuage des pièces forgées en acier. Cette méthode permet de déceler les discontinuités de surface.

Neporušitveno preskušanje jeklenih izkovkov - 2. del: Preskušanje s penetranti

Ta del standarda EN 10228 opisuje metode in prevzemne kriterije, ki se uporabljajo za preskušanje izkovkov s penetranti. Opisana metoda se uporablja za odkrivanje površinskih prekinitev.

General Information

- Status

- Published

- Publication Date

- 31-May-2016

- Withdrawal Date

- 30-Dec-2016

- Technical Committee

- ECISS/TC 111 - Steel castings and forgings

- Drafting Committee

- ECISS/TC 111 - Steel castings and forgings

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 30-Mar-2023

- Completion Date

- 14-Apr-2025

Relations

- Effective Date

- 30-Apr-2011

Overview

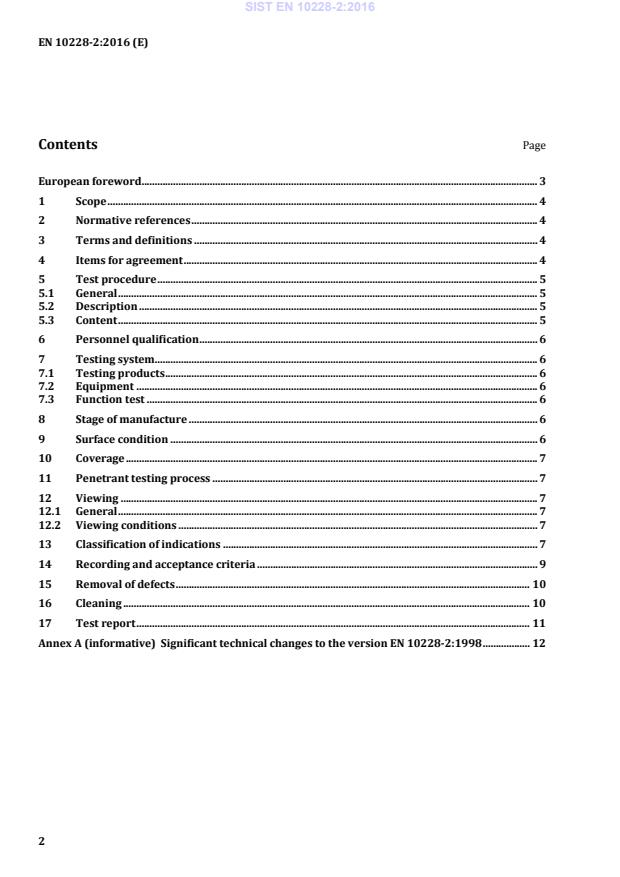

EN 10228-2:2016 - "Non-destructive testing of steel forgings - Part 2: Penetrant testing" is a European standard that defines techniques, procedural requirements and acceptance criteria for using penetrant testing (PT) to detect surface discontinuities in steel forgings. It applies to both colour-contrast and fluorescent penetrants and is intended to ensure consistent, reproducible detection of surface defects during manufacture and final inspection.

Key topics and requirements

- Scope and purpose: Detection of surface discontinuities on steel forgings using penetrant testing.

- Written test procedure: PT must be carried out according to a documented procedure that includes itemized details such as part description, test stage, products, cleaning, application and removal steps, viewing conditions and acceptance criteria.

- Personnel qualification: Operators and inspectors must be qualified per EN ISO 9712.

- Penetrant system: Penetrant, remover/emulsifier and developer shall conform to EN ISO 3452-1; sensitivity checks per EN ISO 3452-2; equipment per EN ISO 3452-4.

- Surface condition and finish: Surfaces must be clean and free of contaminants. Surface roughness guidance is given (e.g., Ra 6.3 acceptable for quality classes 1–4; Ra 12.5 achievable for class 1).

- Viewing conditions:

- Colour-contrast penetrants: minimum ~500 lx white light on the surface (avoid glare).

- Fluorescent penetrants: 5 minutes eye adaptation to reduced lighting and 5 minutes lamp warm-up for UV‑A.

- Coverage: 100% coverage of the specified surface area is recommended where practicable.

- Indication classification and measurement: Rules for linear vs. rounded indications, interacting indications, cumulative lengths and reference-surface measurement (A6 reference 148 × 105 mm).

- Acceptance criteria (quality classes 1–4): Tabulated recording levels and limits include, for example:

- Recording level (mm): 7, 3, 3, 1 (classes 1→4)

- Allowable isolated linear lengths (mm): 20, 8, 4, 2

- Allowable cumulative length per reference surface (mm): 75, 36, 24, 5

- Max number of recordable indications per reference surface: 15, 10, 7, 5 (Quality class 4 is most stringent; class applicability depends on forging type and agreement.)

- Reporting and post-test actions: Written test report required (supplier, order, part ID, scope, quality class, results). Defects outside acceptance must be removed (e.g., grinding/machining) and retested.

Applications and who uses it

- Forging manufacturers and their quality/inspection teams for production and final acceptance testing.

- NDT technicians and inspectors applying penetrant methods on steel forgings.

- Purchasers, OEMs and procurement/QA managers who specify acceptance levels for forgings.

- Certification bodies and auditors verifying compliance to European NDT practice.

Related standards

- EN ISO 3452-1, -2, -4 (Penetrant testing fundamentals, materials, equipment)

- EN ISO 3059 (Viewing conditions)

- EN ISO 9712 (NDT personnel qualification)

- EN ISO 12706 (Penetrant testing vocabulary)

Keywords: EN 10228-2:2016, penetrant testing, non-destructive testing, NDT, steel forgings, fluorescent penetrant, colour contrast, acceptance criteria, EN ISO 3452, EN ISO 9712.

Frequently Asked Questions

EN 10228-2:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "Non-destructive testing of steel forgings - Part 2: Penetrant testing". This standard covers: This European Standard describes techniques and acceptance criteria to be used for the penetrant testing of steel forgings. The method described is used for the detection of surface discontinuities.

This European Standard describes techniques and acceptance criteria to be used for the penetrant testing of steel forgings. The method described is used for the detection of surface discontinuities.

EN 10228-2:2016 is classified under the following ICS (International Classification for Standards) categories: 77.040.20 - Non-destructive testing of metals; 77.140.85 - Iron and steel forgings. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10228-2:2016 has the following relationships with other standards: It is inter standard links to EN 10228-2:1998. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10228-2:2016 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 10228-2:2016 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Neporušitveno preskušanje jeklenih izkovkov - 2. del: Preskušanje s penetrantiZerstörungsfreie Prüfung von Schmiedestücken aus Stahl - Teil 2: EindringprüfungEssais non destructifs des pièces forgées en acier - Partie 2 : Contrôle par ressuageNon-destructive testing of steel forgings - Part 2: Penetrant testing77.140.85Železni in jekleni kovani izdelkiIron and steel forgings77.040.20Neporušitveno preskušanje kovinNon-destructive testing of metalsICS:Ta slovenski standard je istoveten z:EN 10228-2:2016SIST EN 10228-2:2016en,fr,de01-september-2016SIST EN 10228-2:2016SLOVENSKI

STANDARDSIST EN 10228-2:20001DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 10228-2

June

t r s x ICS

y yä r v rä t râ

y yä s v rä z w Supersedes EN

s r t t zæ tã s { { zEnglish Version

Nonædestructive testing of steel forgings æ Part

tã Penetrant testing Essais non destructifs des pièces forgées en acier æ Partie

t ã Contrôle par ressuage

Zerstörungsfreie Prüfung von Schmiedestücken aus Stahl æ Teil

tã Eindringprüfung This European Standard was approved by CEN on

u October

t r s wä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s r t t zæ tã t r s x ESIST EN 10228-2:2016

Significant technical changes to the version EN 10228-2:1998 . 12

...

EN 10228-2:2016は、鋼の鍛造品における非破壊試験のための標準であり、特に浸透試験に焦点を当てた重要な文書です。この標準は、鋼鍛造品の表面の不連続性を検出するために必要な技術と受け入れ基準を詳細に説明しています。浸透試験は、鋼材の表面に微細な亀裂や欠陥がないかを確認するために非常に効果的な方法であり、その信頼性は多くの業界で評価されています。 この標準の大きな強みは、具体的な手法と受け入れ基準を明確に定義している点です。これにより、テストを実施する技術者が一貫した手法を用い、結果を客観的に評価できるようになります。また、EN 10228-2:2016は、鋼の鍛造工程において重要な品質管理手段を提供し、製品の安全性と性能を確保するための重要なフレームワークとなっています。 さらに、この標準は欧州規格であるため、EU市場における競争力を維持するためにも不可欠です。鋼鍛造品を扱う企業は、EN 10228-2:2016を遵守することで、顧客の信頼を築き、規制に適合した製品を提供することが可能です。したがって、浸透試験についてのこの文書は、鋼の鍛造品の評価や品質保証において極めて重要な役割を果たしています。

The EN 10228-2:2016 standard provides a comprehensive guide for the non-destructive testing of steel forgings, specifically focusing on penetrant testing procedures. Its scope is crucial as it delineates the processes and acceptance criteria required to effectively detect surface discontinuities in steel forgings, which are essential for ensuring the integrity and reliability of components used in various engineering applications. One of the primary strengths of this standard lies in its detailed methodology for penetrant testing, which includes both the preparation and execution stages. By adhering to the techniques outlined in EN 10228-2:2016, practitioners can ensure consistent and reliable results during inspections. This is particularly relevant in industries where safety and performance are paramount, such as aerospace, automotive, and construction, further emphasizing the standard's applicability across multiple sectors. Moreover, the standard's emphasis on acceptance criteria cultivates a standardized approach to evaluating test results, which enhances the credibility of the inspection process. The clarity of guidance provided allows inspectors to make informed decisions based on uniformly applied criteria, minimizing ambiguity and variability in the testing outcomes. The relevance of EN 10228-2:2016 in contemporary manufacturing cannot be overstated, as it aligns with the growing industry demand for robust quality assurance practices. As steel forgings remain integral to a wide range of products, maintaining rigorous non-destructive testing protocols through standards such as this one plays a vital role in optimizing operational safety and performance. In summary, the EN 10228-2:2016 standard stands out for its clear, systematic approach to penetrant testing of steel forgings, establishing trustworthy processes that enhance the evaluation of surface discontinuities. Its strengths in techniques and acceptance criteria substantiate its importance as a reliable reference in the field of non-destructive testing.

SIST EN 10228-2:2016 표준은 강재 단조 제품의 비파괴 검사에 관한 중요한 가이드라인을 제공합니다. 이 문서는 침투 검사에 대한 기술과 수용 기준을 상세히 설명하며, 해당 검사 방법이 표면 불연속성을 감지하는 데 사용됩니다. 이 표준의 주요 강점은 강철 단조 제품의 품질 보증을 위해 필수적인 비파괴 검사 방법을 표준화했다는 점입니다. 침투 검사라는 비파괴 검사 기법은 제품의 표면 결함을 효과적으로 выяв하며, 이를 통해 사용자의 안전과 제품의 신뢰성을 확보할 수 있습니다. 또한, EN 10228-2:2016 표준은 제조업체와 검사 기관 간의 일관된 기준을 제공함으로써 산업 전반에 걸쳐 품질 관리를 강화합니다. 이 표준의 적절한 적용은 강철 단조 제품이 해당 산업 기준을 충족하도록 보장하며, 따라서 이 표준은 강철 단조의 비파괴 검사에 있어 필수적인 프레임워크 역할을 수행합니다. 결론적으로, SIST EN 10228-2:2016 표준은 강철 단조 제품의 비파괴 검사에서 침투 검사 방법의 사용을 명확하게 규정하고 있으며, 이는 산업에서의 품질 보증과 안전성 유지에 중요한 역할을 하게 됩니다.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...