IEC 61189-3-913:2016

(Main)Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-913: Test method for thermal conductivity of electronic circuit boards for high-brightness LEDs

Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-913: Test method for thermal conductivity of electronic circuit boards for high-brightness LEDs

IEC 61189-3-913:2016 specifies the test methods for thermal conductivity specific to printed circuit boards for high-brightness LEDs. The test applies to printed circuit boards for high-brightness LEDs with surface mounted LEDs or with device embedded LEDs in electronic control devices (ECDs). This first edition cancels and replaces the first edition of IEC PAS 61189-3-913 published in 2011. This edition constitutes a technical revision. This edition focused only on the test methods for thermal conductivity specific to printed circuit boards for high-brightness LEDs.

Méthodes d'essai pour les matériaux électriques, les cartes imprimées et autres structures d'interconnexion et ensembles - Partie 3-913: Méthodes d'essais pour la conductivité thermique des circuits imprimés pour les LED à forte luminosité

L'IEC 61189-3-913:2016 spécifie les méthodes d'essai relatives à la conductivité thermique spécifique aux circuits imprimés des LED à forte luminosité. L'essai est applicable aux circuits imprimés pour les LED à forte luminosité, les LED pour montage en surface ou les LED intégrées à un appareil dans des dispositifs de commande électroniques (ECD, Electronic Control Device). Cette première édition annule et remplace la première édition de l'IEC PAS 61189-3-913 parue en 2011. Cette édition constitue une révision technique. Cette édition est consacrée uniquement aux méthodes d essai relatives à la conductivité thermique spécifique aux circuits imprimés des LED à forte luminosité.

Aluminium-magnesium-silicon alloy wire for overhead line conductors

General Information

- Status

- Published

- Publication Date

- 04-Jan-2016

- Technical Committee

- TC 91 - Electronics assembly technology

- Drafting Committee

- WG 10 - TC 91/WG 10

- Current Stage

- PPUB - Publication issued

- Start Date

- 15-Jan-2016

- Completion Date

- 05-Jan-2016

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61189-3-913:2016 is an international standard published by the International Electrotechnical Commission (IEC) outlining specific test methods for determining the thermal conductivity of printed circuit boards (PCBs) used in high-brightness light-emitting diode (LED) applications. This standard targets PCBs with surface-mounted LEDs or embedded LED devices integrated in electronic control devices (ECDs). As a technical revision, it updates and replaces the previous edition published in 2011, focusing exclusively on test methodologies for thermal conductivity relevant to high-brightness LED PCBs.

Thermal management is critical in LED technology to ensure performance, reliability, and longevity. IEC 61189-3-913 establishes standardized procedures for accurately measuring thermal conductivity to support the design and evaluation of heat dissipation properties in PCB materials tailored for LED applications.

Key Topics

Scope and Applicability

The standard applies to printed circuit boards designed for high-brightness LEDs including both surface-mounted and device-embedded LED configurations within electronic control systems.Thermal Conductivity Testing

Detailed methods for measuring thermal conductivity of electronic circuit board materials are specified, enabling consistent and reliable data across laboratories and manufacturers.Material Considerations

The standard addresses the characteristics of PCB materials that influence heat transfer, ensuring test methods are adapted to board compositions used specifically in LED-related electronics.Technical Revision Highlights

This edition streamlines focus on thermal conductivity testing, removing unrelated content from prior editions to provide clearer guidance for the LED PCB industry.

Applications

High-Brightness LED PCB Design

Designers use IEC 61189-3-913 methods to select or validate PCB materials with adequate thermal conductivity, critical for preventing heat buildup in LED assemblies.Thermal Management in LED Devices

Manufacturers apply the test protocols to evaluate and improve heat dissipation strategies, enhancing LED device performance and lifespan.Quality Assurance and Compliance

Test results guided by this standard support quality control processes and fulfill regulatory or customer requirements related to thermal performance.Research and Development

R&D teams leverage standardized thermal conductivity measurements to innovate advanced PCB materials and structures optimized for high-brightness LED applications.

Related Standards

IEC 61189 Series

Covers test methods for electrical materials and printed boards, including other parts addressing mechanical, electrical, and environmental testing elements.IEC 62384

Deals with LED driver specifications, often used in conjunction with thermal management standards to ensure overall LED system reliability.ISO 22007

Standard for thermal properties measurement of materials, which may provide complementary methods for broader research contexts.IPC-2XX Series

Industry standards for PCB fabrication and testing often referencing IEC protocols to maintain consistency in electronic manufacturing.

Summary

IEC 61189-3-913:2016 is a vital standard for the electronics and LED manufacturing industries, establishing rigorous and repeatable thermal conductivity test methods for PCB materials in high-brightness LED applications. Compliance ensures optimal thermal management, contributing to enhanced LED device performance, safety, and reliability. By adopting this standard, stakeholders can accurately assess material properties, support innovation in LED circuit board design, and meet international quality benchmarks.

IEC 61189-3-913:2016 - Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-913: Test method for thermal conductivity of electronic circuit boards for high-brightness LEDs

Frequently Asked Questions

IEC 61189-3-913:2016 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Test methods for electrical materials, printed boards and other interconnection structures and assemblies - Part 3-913: Test method for thermal conductivity of electronic circuit boards for high-brightness LEDs". This standard covers: IEC 61189-3-913:2016 specifies the test methods for thermal conductivity specific to printed circuit boards for high-brightness LEDs. The test applies to printed circuit boards for high-brightness LEDs with surface mounted LEDs or with device embedded LEDs in electronic control devices (ECDs). This first edition cancels and replaces the first edition of IEC PAS 61189-3-913 published in 2011. This edition constitutes a technical revision. This edition focused only on the test methods for thermal conductivity specific to printed circuit boards for high-brightness LEDs.

IEC 61189-3-913:2016 specifies the test methods for thermal conductivity specific to printed circuit boards for high-brightness LEDs. The test applies to printed circuit boards for high-brightness LEDs with surface mounted LEDs or with device embedded LEDs in electronic control devices (ECDs). This first edition cancels and replaces the first edition of IEC PAS 61189-3-913 published in 2011. This edition constitutes a technical revision. This edition focused only on the test methods for thermal conductivity specific to printed circuit boards for high-brightness LEDs.

IEC 61189-3-913:2016 is classified under the following ICS (International Classification for Standards) categories: 29.060.10 - Wires; 29.240.20 - Power transmission and distribution lines; 31.180 - Printed circuits and boards. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61189-3-913:2016 has the following relationships with other standards: It is inter standard links to IEC PAS 61189-3-913:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase IEC 61189-3-913:2016 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of IEC standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-1999

Aluminium-magnesium-silicon alloy wire for overhead line conductors

Aluminium-magnesium-silicon alloy wire for overhead line conductors

Fils en alliage d'aluminium-magnésium-silicium pour conducteurs de lignes aériennes

Ta slovenski standard je istoveten z: IEC 60104

ICS:

29.060.10 Žice Wires

29.240.20 Daljnovodi Power transmission and

distribution lines

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

NORME CEI

INTERNATIONALE IEC

INTERNATIONAL

Deuxième édition

STAN DARD

Second edition

1987-12

Fils en alliage d'aluminium-magnésium-silicium

pour conducteurs de lignes aériennes

Aluminium-magnesium-silicon alloy wire

for overhead line conductors

© IEC 1987

Droits de reproduction réservés —

Copyright - all rights reserved

Aucune partie de

cette publication ne peut être reproduite ni No part of this publication may be reproduced or utilized in

utilisée quelque

sous forme que ce soit et par aucun any form or by any means, electronic or mechanical,

procédé, électronique ou mécanique, y compris la photo- including photocopying and microfilm, without permission in

copie et les microfilms, sans l'accord écrit de l'éditeur. writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http: //www.iec.ch

CODE PRIX

Commission Electrotechnique Internationale

F

PRICE CODE

International Electrotechnical Commission

IEC MemitiviapoAHaR 3neKTpOTexHN4eCHÜN KOMHCC1111

Pour prix, voir catalogue en vigueur

• • For price, see current catalogue

104 © IEC 1987 –3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

ALUMINIUM-MAGNESIUM-SILICON ALLOY WIRE

FOR OVERHEAD LINE CONDUCTORS

FOREWORD

1) The formal decisions or agreements of the I E C on technical matters, prepared by Technical Committees on which all the

National Committees having a special interest therein are represented, express, as nearly as possible, an international

consensus of opinion on the subjects dealt with.

2)

They have the form of recommendations for international use and they are accepted by the National Committees in that sense.

3) fi

In order to promote international uni cation, the I E C expresses the wish that all National Committees should adopt the text

of the I E C recommendation for their national rules in so far as national conditions will permit. Any divergence between the

I E C recommendation and the corresponding national rules should, as far as possible, be clearly indicated in the latter.

PREFACE

This standard has been prepared by I E C Technical Committee No. 7 : Bare Aluminium Conductors.

This second edition of I E C Publication 104 replaces the first edition, which was issued in 1958.

This standard replaces Clauses 3, 5, 6 and 13, and the requirements of Clauses 4 and 12 and Sub-

clause 8.1 of I E C Publication 208 (1966) : Aluminium Alloy Stranded Conductors (Aluminium-

Magnesium-Silicon Type). It also replaces Clauses 3, 6, 15, Sub-clause 7.1 and the requirements of

Clause 5, Sub-clauses 9.1, 13.2 and 13.3 of IEC Publication 210 (1966) : Aluminium Alloy

Conductors, Steel-reinforced.

The text of this standard is based on the following documents:

Six Months' Rule Report on Voting

7(CO)420 7(CO)423

Further information can be found in the Report on Voting indicated in the table above.

The following !EC publication is quoted in this standard:

Publication No. 468 (1974): Method of Measurement of Resistivity of Metallic Materials.

Other publications quoted:

ISO Standard 6892 (1984) : Metallic Materials – Tensile Testing.

ISO Standard 7802 (1983): Metallic Materials – Wire-Wrapping Test.

104 © I E C – 5

ALUMINIUM-MAGNESIUM-SILICON ALLOY WIRE

FOR OVERHEAD LINE CONDUCTORS

1. Scope

This standard is applicable to aluminium-magnesium-silicon alloy wires of two types having

different mechanical and electrical properties for the manufacture of stranded conductors for

overhead power transmission purposes. It specifies the mechanical and electrical properties of

wires in the diameter range 1.50 mm to 4.50 mm.

The two types are designated Type A and Type B respectively.

Values for alumini

...

IEC 61189-3-913 ®

Edition 1.0 2016-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 3-913: Test method for thermal conductivity of printed circuit boards for

high-brightness LEDs

Méthodes d'essai pour les matériaux électriques, les cartes imprimées et autres

structures d'interconnexion et ensembles –

Partie 3-913: Méthodes d'essai pour la conductivité thermique des circuits

imprimés pour les LED à forte luminosité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

65 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 61189-3-913 ®

Edition 1.0 2016-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Test methods for electrical materials, printed boards and other interconnection

structures and assemblies –

Part 3-913: Test method for thermal conductivity of printed circuit boards for

high-brightness LEDs

Méthodes d'essai pour les matériaux électriques, les cartes imprimées et autres

structures d'interconnexion et ensembles –

Partie 3-913: Méthodes d'essai pour la conductivité thermique des circuits

imprimés pour les LED à forte luminosité

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 31.180 ISBN 978-2-8322-3104-3

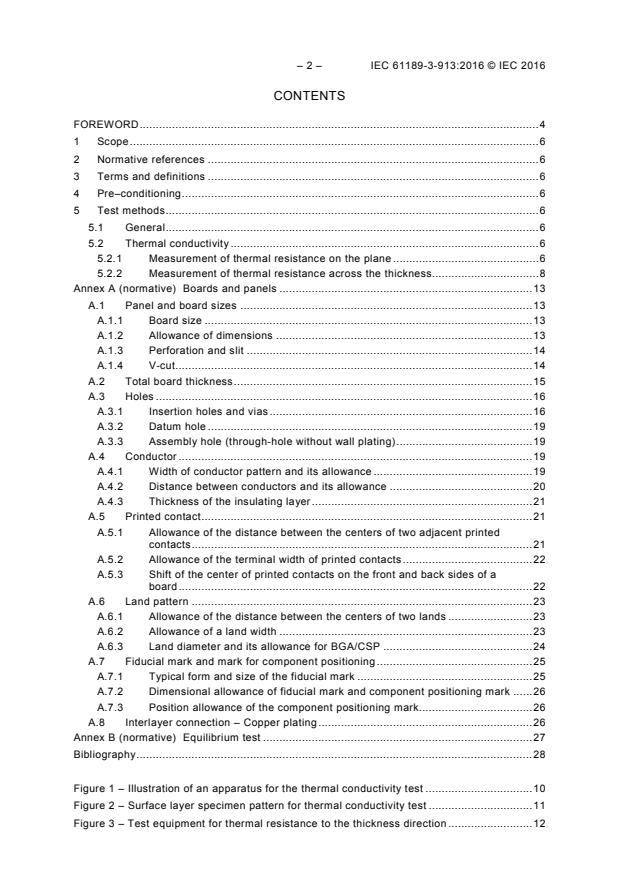

– 2 – IEC 61189-3-913:2016 © IEC 2016

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Pre–conditioning . 6

5 Test methods . 6

5.1 General . 6

5.2 Thermal conductivity . 6

5.2.1 Measurement of thermal resistance on the plane . 6

5.2.2 Measurement of thermal resistance across the thickness . 8

Annex A (normative) Boards and panels . 13

A.1 Panel and board sizes . 13

A.1.1 Board size . 13

A.1.2 Allowance of dimensions . 13

A.1.3 Perforation and slit . 14

A.1.4 V-cut. 14

A.2 Total board thickness . 15

A.3 Holes . 16

A.3.1 Insertion holes and vias . 16

A.3.2 Datum hole . 19

A.3.3 Assembly hole (through-hole without wall plating) . 19

A.4 Conductor . 19

A.4.1 Width of conductor pattern and its allowance . 19

A.4.2 Distance between conductors and its allowance . 20

A.4.3 Thickness of the insulating layer . 21

A.5 Printed contact . 21

A.5.1 Allowance of the distance between the centers of two adjacent printed

contacts . 21

A.5.2 Allowance of the terminal width of printed contacts . 22

A.5.3 Shift of the center of printed contacts on the front and back sides of a

board . 22

A.6 Land pattern . 23

A.6.1 Allowance of the distance between the centers of two lands . 23

A.6.2 Allowance of a land width . 23

A.6.3 Land diameter and its allowance for BGA/CSP . 24

A.7 Fiducial mark and mark for component positioning . 25

A.7.1 Typical form and size of the fiducial mark . 25

A.7.2 Dimensional allowance of fiducial mark and component positioning mark . 26

A.7.3 Position allowance of the component positioning mark. 26

A.8 Interlayer connection – Copper plating . 26

Annex B (normative) Equilibrium test . 27

Bibliography . 28

Figure 1 – Illustration of an apparatus for the thermal conductivity test . 10

Figure 2 – Surface layer specimen pattern for thermal conductivity test . 11

Figure 3 – Test equipment for thermal resistance to the thickness direction . 12

Figure A.1 – Board arrangement in a panel . 13

Figure A.2 – Distances from the datum point to perforation and slit . 14

Figure A.3 – Distance from the datum point to the V-cut . 15

Figure A.4 – Allowance of position off-set of V-cuts on front and back surfaces . 15

Figure A.5 – PWB board with symbol mark, solder resist, copper foil and plating . 16

Figure A.6 – Positions of component insertion holes . 17

Figure A.7 – Distance between the wall of a hole and the board edge . 18

Figure A.8 – Wall of a hole and the minimum designed spacing to the inner conductor . 19

Figure A.9 – Width of finished conductor . 20

Figure A.10 – Distance between conductor and board edge . 21

Figure A.11 – Thickness of the insulating layer . 21

Figure A.12 – Distance between centers of terminals of printed contacts . 22

Figure A.13 – Terminal width of a printed contact . 22

Figure A.14 – Shift of the center of printed contacts on front and back sides of a board . 23

Figure A.15 – Land pattern . 23

Figure A.16 – Land width of a land pattern . 24

Figure A.17 – Land diameter of BGA/CSP formed of a conductor only . 24

Figure A.18 – Land diameter (d) of BGA/CSP formed at the opening of solder resist . 25

Figure A.19 – Examples of fiducial mark and component positioning mark . 26

Table 1 – Applied power (P) that corresponds to a range of thermal resistance

on the plane . 8

Table 2 – Applied power (P) that corresponds to a range of thermal resistance

across the thickness (K/W) . 9

Table A.1 – Panel dimensions . 13

Table A.2 – Allowance of dimensions . 14

Table A.3 – Allowance of the distances from the datum point to perforation and slit . 14

Table A.4 – Allowance of the distance from the datum point to the center of the V-cut . 15

Table A.5 – Total thickness and its allowance . 16

Table A.6 – Allowance of holes for component insertion. 16

Table A.7 – Position allowance of component insertion holes . 17

Table A.8 – Distance between the wall of a hole and board edge . 18

Table A.9 – Minimum clearance between the wall of a hole and the inner layer

conductor . 18

Table A.10 – Allowance of conductor width . 20

Table A.11 – Allowance of the distance between conductors . 20

Table A.12 – Allowance of terminal width of a printed contact . 22

Table A.13 – Allowance of terminal width of a printed contact . 23

Table A.14 – Allowance of the width of a land of a land pattern . 24

Table A.15 – Land diameter and its allowance for BGA/CSP . 25

Table A.16 – Allowance of the land diameter (d) of BGA/CSP formed at the opening of

solder resist . 25

Table A.17 – Shapes and sizes of typical fiducial marks and component positioning

marks . 26

Table A.18 – Minimum thickness of copper plating . 26

– 4 – IEC 61189-3-913:2016 © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS AND

OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 3-913: Test method for thermal conductivity of printed

circuit boards for high-brightness LEDs

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61189-3-913 has been prepared by IEC technical committee 91:

Electronics assembly technology.

This first edition cancels and replaces the first edition of IEC PAS 61189-3-913 published in

2011. This edition constitutes a technical revision. This edition focused only on the test

methods for thermal conductivity specific to printed circuit boards for high-brightness LEDs.

The text of this standard is based on the following documents:

FDIS Report on voting

91/1304A/FDIS 91/1328/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

A list of all parts in the IEC 61189, published under the general title Test methods for

electrical materials, printed boards and other interconnection structures and assemblies, can

be found on the IEC website.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 61189-3-913:2016 © IEC 2016

TEST METHODS FOR ELECTRICAL MATERIALS, PRINTED BOARDS AND

OTHER INTERCONNECTION STRUCTURES AND ASSEMBLIES –

Part 3-913: Test method for thermal conductivity of printed

circuit boards for high-brightness LEDs

1 Scope

This part of IEC 61189 specifies the test methods for thermal conductivity specific to printed

circuit boards for high-brightness LEDs. The test applies to printed circuit boards for high-

brightness LEDs with surface mounted LEDs or with device embedded LEDs in electronic

control devices (ECDs).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60194, Printed board design, manufacture and assembly – Terms and definitions

IEC 62326-20, Printed boards – Part 20: Printed circuit boards for high-brightness LEDs

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60194 apply, unless

otherwise specified.

4 Pre–conditioning

Pre-conditioning described in a) or b) below shall be carried out in accordance with the

specific standard.

a) Leave a specimen for 24 h in the standard condition.

b) Leave a specimen for 60 min in a thermostat chamber at 85 °C and then leave the

specimen for 24 ± 4 h in the standard atmospheric condition.

5 Test methods

5.1 General

In this standard, the following test methods are specified in order to classing the printed

circuit board in accordance with Table 1 in IEC 62326-20.

5.2 Thermal conductivity

5.2.1 Measurement of thermal resistance on the plane

In this subclause, the measurement of thermal resistance on the plane (horizontal direction of

the specimen) is addressed as follows.

a) Apparatus

Use the apparatus specified in EIA/JEDEC STD 51-2, or equivalent. The equipment shall

have a set of a specimen and a thermocouple in the centre of a cubic chamber of 30 cm

side length. An apparatus is shown in Figure 1.

b) Specimen

Unless otherwise specified, use the specimen illustrated in Figure 2. All the dimensions in

Figure 2 shall be requirements. This specimen uses a TEG chip (5 mm × 5 mm) with a

temperature measuring sensor, which is wire-bonded to the centre of the specimen board

as a heat source. The detail specification of the printed board shall be in accordance with

Annex A.

c) Pre-conditioning

Pre-conditioning shall be in accordance with Clause 4. And, the test specimen shall be

fixed horizontally in the chamber of the equipment.

d) Thermal resistance and heat transfer parameter on the plane (horizontal direction of the

specimen). The following procedure shall be respected:

• provide a specimen assembled with a heater with a TEG chip with a temperature

measuring sensor;

• specify the temperature coefficient of the sensor prior to the measurement;

• operate the heater and arrange the applied power (P) based upon the range of thermal

resistance on the plane (horizontal direction of the specimen) as shown in Table 1;

• measure the temperature of the TEG chip with a temperature measuring sensor (T )

s

and the temperature inside the chamber (T ) after the temperature of the TEG chip

a

with a temperature measuring sensor has reached a stable state;

• calculate the thermal resistance on the plane (horizontal direction of the specimen)

(R ) with the following equation:

p

R = (T – T ) / P

p s a

• using the thermal resistance (R ), calculate the thermal transfer parameter (he) by the

p

following equation:

he = W/m K

R × 0,002 5

p

Equilibrium verification shall be in accordance with Annex B.

– 8 – IEC 61189-3-913:2016 © IEC 2016

Table 1 – Applied power (P) that corresponds to a range of thermal

resistance on the plane

Range of thermal resistance

Applied power on the plane

(horizontal direction of the specimen) (R )

p

W K/W

0,1 300 > R

p

0,2 200 < R < 300

p

0,3 150 < R < 200

p

0,4 100 < R < 150

p

0,75

60 < R < 100

p

1,0 30 < R < 60

p

2,0 20 < R < 30

p

3,0 15 < R < 20

p

5,0 5 < R < 15

p

10,0 < 5

R

p

5.2.2 Measurement of thermal resistance across the thickness

In this subclause, the measurement of thermal resistance across the thickness is addressed

as follows.

a) Apparatus

The testing apparatus is as shown in Figure 3. The apparatus shall consist of a metal

block (aluminium or copper) which can hold the specimen specified in 5.2.1 b) and a

cooling system to keep the temperature of the metal block constant.

b) Specimen

Specimen shall be as specified in 5.2.1 b).

c) Pre-conditioning

Pre-conditioning shall be in accordance with Clause 4.

d) Test

The procedure shall be as follows:

• provide a specimen, which is screwed to the metal block, assembled with a heater that

contains a TEG chip with a temperature measuring sensor;

• specify the temperature coefficient of the sensor prior to the measurement;

• apply thermal conductive materials such as thermal grease between the specimen and

the metal block to reduce thermal resistivity;

• install a thermocouple within a 10 mm distance from the edge of the specimen;

• install another thermocouple in the water sink;

• fix the metal block to the cooling system;

• keep the water temperature constant by the water-cooled system as shown in

Figure 3;

• operate the heater and arrange the applied power (P) based on the thermal resistance

across the thickness, as shown in Table 2;

• measure the temperature of the TEG chip with a temperature measuring sensor (T )

s

and the temperature on the metal block (T ) as soon as the temperature of the TEG

b

chip with a temperature measuring sensor has reached the stable state;

• calculate the thermal resistance across the thickness (R ) by the following equation:

t

R = (T − T ) /P (K/W)

t s b

The thermal conductivity parameter (Ke) shall be calculated with the following equation using

R .

t

t

Ke = W/m K

−5

R × 2,5 ×10

t

where

t is the thickness (m);

–5 2

2,5 × 10 (m ) is the area of the TEG chip with a temperature measuring sensor.

Table 2 – Applied power (P) that corresponds to a range of thermal

resistance across the thickness (K/W)

Applied power Range of thermal resistance across the thickness (R )

t

W K/W

0,1

300 > R

t

0,2

200 < R < 300

t

0,3 150 < R < 200

t

0,4 100 < R < 150

t

0,75 60 < R < 100

t

1,0

30 < R < 60

t

2,0

20 < R < 30

t

3,0 15 < R < 20

t

5,0 5 < R < 15

t

10,0

R < 5

t

– 10 – IEC 61189-3-913:2016 © IEC 2016

Dimensions in millimetres

Thermocouple

Specimen

Arrange as to the heating

TEG (test equipment

group) to the center of the

cabinet

Package mounted

on board for test

12,5

TEG chip

Support

Thermocouple

Thermocouple

IEC

Figure 1 – Illustration of an apparatus for the thermal conductivity test

12,5

Dimensions in millimetres

TEG pad

2 1

3,2 25

Mounting hole

Pad

Wire bonding pad

TEG

Substrate

Grease

IEC

Figure 2 – Surface layer specimen pattern for thermal conductivity test

14 2 5

3,2

4,5

– 12 – IEC 61189-3-913:2016 © IEC 2016

Water cooled heat sink (AI or Cu) block

100 mm × 100 mm × 50 mm

10 mm

TEG chip

Specimen

Screw

Thermocouple Thermal grease

Thermocouple

Running

water

Constant water temperature (from 15 °C to 25 °C)

IEC

Figure 3 – Test equipment for thermal resistance to the thickness direction

Annex A

(normative)

Boards and panels

A.1 Panel and board sizes

A.1.1 Board size

This subclause is given for reference only. The size of the board of the product (a × b)

illustrated in Figure A.1 should be selected so that the boards can be arranged efficiently

within a panel with a size as specified in Table A.1. These dimensions are given for

information only. Or, a proper panel with a size given in Table A.1 shall be selected so as to

satisfy the required efficient arrangement of the boards.

Printed board

Panel

e

c b b c

3 4

IEC

Key

Board size of the product: a × b

Space between board and panel edges: c , c , c , c

1 2 3 4

Space between boards: e , e

1 2

Figure A.1 – Board arrangement in a panel

Table A.1 – Panel dimensions

Size of a CCL Division

(copper clad

4 6 8 9

laminate) panel

1 000 × 1 000 500 × 500 333 × 500 250 × 500 333 × 333

333 × 600

1 000 × 1 200 500 × 600 300 × 500 333 × 400

400 × 500

Dimensions are in millimetres.

A.1.2 Allowance of dimensions

The allowance of dimensions of a board or a panel is given in Table A.2.

a a

c e c

2 2 1

– 14 – IEC 61189-3-913:2016 © IEC 2016

Table A.2 – Allowance of dimensions

Length Allowance

mm mm

≤100 ±0,2

Add 0,1 for each 50 exceeding a length of 100.

>100

A.1.3 Perforation and slit

The perforation and slits are shown in Figure A.2. The allowances of the distances from the

datum point to the center of the cut of the perforation and slit is given in Table A.3.

Outline of the

printed board

Perforation

Slit

f

Datum point

f

IEC

Figure A.2 – Distances from the datum point to perforation and slit

Table A.3 – Allowance of the distances from

the datum point to perforation and slit

Distances from the datum

Allowance

point to perforation and slit

mm

mm

≤100 ±0,2

>100 Add 0,1 for each 50 beyond a length of 100.

A.1.4 V-cut

The V-cut is shown in Figure A.3 and Figure A.4. The allowance of the distance from the

reference datum to the center of cut of the V (g to g ) is given in Table A.4. The allowance of

1 4

the deviation of the position of the V-cut on the front and back planes is 0,2 mm, and the

allowance of the uncut thickness of the board is the sum of the allowance of the board

thickness ±0,1 mm.

f

f

Outline of the

printed board

V-cut

g

Datum point

g

IEC

Figure A.3 – Distance from the datum point to the V-cut

Center of the V-cut

i

(front surface)

Base material

Center of the V-cut

(back surface)

IEC

Figure A.4 – Allowance of position off-set of V-cuts on front and back surfaces

Table A.4 – Allowance of the distance from the datum point to the center of the V-cut

Distance from the datum point

Allowance

to the center of the V-cut

mm

mm

≤100 ±0,2

Add 0,1 for each 50 mm exceeding a length over

>100

100 mm

A.2 Total board thickness

The allowance of the total board thickness (t) and symbol marks as shown in Figure A.5 is

given in Table A.5.

g

g

t

– 16 – IEC 61189-3-913:2016 © IEC 2016

Solder resist

Legend

Plating

Copper foil

IEC

Figure A.5 – PWB board with symbol mark, solder resist, copper foil and plating

Table A.5 – Total thickness and its allowance

Total thickness Allowance

(center value of the final board)

t

+0,10

0,3 ≤ t < 0,5

–0,05

0,5 ≤ t < 0,8 ±0,10

0,8 ≤ t < 1,10

±0,15

1,10 ≤ t < 1,40 ±0,17

1,40 ≤ t < 2,00 ±0,19

t ≥ 2,00 ±10 %

Dimensions are in millimetres.

A.3 Holes

A.3.1 Insertion holes and vias

The following requirements apply for insertion holes and vias.

a) Allowance of component insertion holes

The allowance of component insertion holes is given in Table A.6. The allowance given in

this table is not applicable to vias (through-hole vias, buried vias and blind vias). The

allowance of through-holes with a diameter less than 0,6 mm for insertion of a component

and holes for press-fit of a component is to be as agreed between the user and supplier

(hereafter, referred to as AABUS).

Table A.6 – Allowance of holes for component insertion

Item Allowance

0,6 ≤ t < 2,0 ±0,10

Plated through-hole

t ≥ 2,0

±0,15

Non-plated through-hole ±0,10

Dimensions are in millimetres.

t

b) Position of a hole for component insertion

The center of a hole for component insertion should be at the cross point of the grid for

pattern design including the complementary grid lines used. The allowance of a component

→

insertion hole position the deviation from the designed position in respect to the datum

j

,

point as shown in Figure A.6 is given in Table A.7.

→

| j |

Finished hole

Designed hole position

Quasi datum point

Datum point

(X, Y)

(0,0)

X

Datum line

Outline of the printed board

IEC

Figure A.6 – Positions of component insertion holes

Table A.7 – Position allowance of component insertion holes

Longer dimension of rectangular board Allowance

mm mm

≤400 0,10

>400 For board exceeding 400, add 0,05 for each additional 100

c) Distance from the board edge to the wall of a hole

Distance from the board edge to the wall of a hole (d) is shown in Figure A.7. The distance

(d) between the walls of a through-hole before plating and of a hole for component

insertion shall be larger than either 1,0 mm. The distance in the case of hole for press-fit

shall be in accordance with Table A.8.

Y

– 18 – IEC 61189-3-913:2016 © IEC 2016

Hole

Printed board

d

d

d

t

IEC

Figure A.7 – Distance between the wall of a hole and the board edge

Table A.8 – Distance between the wall of a hole and board edge

Item Distance (j) between a component hole before plating and the via wall (d)

HDI PWB ≤1,0 mm and also longer than the board thickness (t)

Standard PWB ≤1,5 mm and also longer than the board thickness (t)

d) Minimum clearance between the wall of a hole and the inner conductor

The minimum clearance between the wall of a hole and the inner conductor (k) as

illustrated in Figure A.8 shall be 0,325 mm. And the detailed dimensions are specified in

Table A.9. If the distance 0,325 mm is guaranteed in the design of the pattern, the

minimum separation is guaranteed.

Table A.9 – Minimum clearance between the wall of a hole and the inner layer conductor

Minimum clearance between the hole wall

and the inner layer conductor

k

Item

Standard value Minimum value

mm mm

Component hole 0,5

HDI PWB 0,25

Via 0,30

Component hole 0,5

Standard PWB 0,30

Via 0,35

d

Base material

Copper foil

k k

Through-hole plating

IEC

Figure A.8 – Wall of a hole and the minimum designed spacing to the inner conductor

A.3.2 Datum hole

+0,10

The allowance of a datum hole shall be ±0,05 mm, or mm. A through-hole without wall

−0,00

plating shall be used as a datum hole.

A.3.3 Assembly hole (through-hole without wall plating)

The following requirements apply.

a) Allowance of an assembly hole

The allowance of an assembly hole shall be ±0,10 mm.

b) Allowance of the position of an assembly hole

The allowance of the position of an assembly hole shall be in accordance with Table A.7.

c) Distance between an assembly hole and the board edge

The distance between an assembly hole and the board edge shall be larger than 2,0 mm.

In case the distance is less than 2,0 mm, the distance shall be agreed between user and

supplier.

d) The distance between an assembly hole and the inner conductor

The distance between the wall of an assembly hole and the inner conductor shall be larger

than 1,0 mm.

A.4 Conductor

A.4.1 Width of conductor pattern and its allowance

The allowance of the formed conductor width (w), as illustrated in Figure A.9, shall be in

accordance with the allowances given in Table A.10. The allowance of the finished conductor

pattern specifically designed for impedance control shall be AABUS.

– 20 – IEC 61189-3-913:2016 © IEC 2016

Table A.10 – Allowance of conductor width

Conductor thickness (t) Allowance Conductor width for reference

µm µm µm

50 ≤ t < 75 15 to 20

±25

20 to 40

75 ≤ t < 100 ±30

100 ≤ t < 300 ±50 30 to 50

t ≥ 300 ±100 40 to 70

±150

Thick copper foil circuits ±200 105

±300 140

The conductor thickness is the copper foil thickness plus the thickness of plated copper.

Conductor

w w

Base material

IEC

Figure A.9 – Width of finished conductor

A.4.2 Distance between conductors and its allowance

Distance between conductor and board edge is illustrated in Figure A.10. The allowance of

the distance between conductors (h) shall be as given in Table A.11. The allowance of the

finished conductor pattern specifically designed for impedance control shall be AABUS.

Table A.11 – Allowance of the distance between conductors

Conductor thickness (h) Allowance Conductor with for reference

µm µm µm

50 ≤ h < 75 ±25 15 to 20

75 ≤ h < 100 20 to 40

±30

100 ≤ h < 300 ±50 30 to 50

h ≥300 ±100 40 to 70

The conductor thickness is the copper foil thickness plus the thickness of plated copper.

m m

Conductor

Base material

n n

IEC

Key

m is the conductor spacing

n is the conductor pitch

Figure A.10 – Distance between conductor and board edge

A.4.3 Thickness of the insulating layer

The thickness of an insulating layer (t) is illustrated in Figure A.11.

Conductor

Base material

IEC

NOTE In case the surface of copper foil is roughened, the thickness of the base material is the minimum distance

applicable to the substrate.

Figure A.11 – Thickness of the insulating layer

A.5 Printed contact

A.5.1 Allowance of the distance between the centers of two adjacent printed

contacts

The allowance of the distance between the centers of two adjacent printed contacts (p, p ) as

n

illustrated in Figure A.12 shall be ±0,10 mm. Add 0,01 mm for each additional 20 mm in case

the distance between the centers of terminals exceeds 100 mm.

t

t

t

– 22 – IEC 61189-3-913:2016 © IEC 2016

Centres of terminals

of printed contacts

P

P

n

Printed board

IEC

Figure A.12 – Distance between centers of terminals of printed contacts

A.5.2 Allowance of the terminal width of printed contacts

The allowance of the terminal width of printed contacts (w) as illustrated in Figure A.13 is

specified in Table A.12.

Printed contact

w w

IEC

Figure A.13 – Terminal width of a printed contact

Table A.12 – Allowance of terminal width of a printed contact

Terminal width (w) Allowance

mm mm

≤1,0 ±0,05

>1,0 ±0,10

A.5.3 Shift of the center of printed contacts on the front and back sides of a board

The allowance of the shift of the center of printed contacts on the front and back sides of a

board (q) as illustrated in Figure A.14 shall be ±0,20 mm.

q

Printed contact

Base material

IEC

Figure A.14 – Shift of the center of printed contacts

on front and back sides of a board

A.6 Land pattern

A.6.1 Allowance of the distance between the centers of two lands

The allowance of the distance between the centers of two adjacent lands (S ) and of two

parallelly located lands (S) as illustrated in Figure A.15 is specified in Table A.13.

Center of land

S

S

IEC

Figure A.15 – Land pattern

Table A.13 – Allowance of terminal width of a printed contact

Allowance

Distance between centers

mm

S ±0,03

S

±0,05

A.6.2 Allowance of a land width

The allowance of a land width of a land pattern (w) as illustrated in Figure A.16 is specified in

Table A.14. The allowance for a land narrower than 0,15 mm shall be AABUS.

S

S

– 24 – IEC 61189-3-913:2016 © IEC 2016

w

Land

w

w

Center of land

IEC

Figure A.16 – Land width of a land pattern

Table A.14 – Allowance of the width of a land of a land pattern

Land width

Allowance

w

0,15 < w ≤ 0,35 ±0,04

w > 0,35 ±0,06

Dimensions are in millimetres.

A.6.3 Land diameter and its allowance for BGA/CSP

The allowance of land diameter for BGA/CSP is specified in a) and b) below.

a) The pattern is shown in Figure A.17. The allowance of the land diameter (d) of BGA/CSP

made of a conductor only is given in Table A.15.

Land

Land

Conductor

Base material

Conductor

d d

Base material

IEC

Figure A.17 – Land diameter of BGA/CSP formed of a conductor only

w

Table A.15 – Land diameter and its allowance for BGA/CSP

Allowance of land diameter Conductor thickness

Item

a

mm µm

+0,02

HDI PWB 20 to 30

–0,03

+0,03

Standard PWB 30 to 50

–0,05

a

For reference only.

b) The pattern is shown in Figure A.18. The allowance of the land diameter (d) of BGA/CSP

formed at the opening of solder resist is given in Table A.16.

Table A.16 – Allowance of the land diameter (d) of BGA/CSP

formed at the opening of solder resist

Allowance

Item

mm

HDI PWB ±0,03

Standard PWB ±0,05

Solder resist

Land

Solder resist

d

Base material

Conductor

IEC

Figure A.18 – Land diameter (d) of BGA/CSP

formed at the opening of solder resist

A.7 Fiducial mark and mark for component positioning

A.7.1 Typical form and size of the fiducial mark

The mark for component positioning in Figure A.19 is specified in Table A.17.

...

글 제목: IEC 61189-3-913:2016 - 전기 재료, 인쇄 기판 및 기타 인터커넥션 구조 및 조립물을 위한 시험 방법 - Part 3-913: 고밝기 LED 전자 회로 기판의 열전도성에 대한 시험 방법 글 내용: IEC 61189-3-913:2016은 고밝기 LED용 인쇄 회로 기판에 대한 열전도성 테스트 방법을 규정합니다. 이 시험은 표면 장착 LED가 있는 고밝기 LED용 인쇄 회로 기판이나 전자 제어 장치(ECD)에 장착된 장치가 있는 인쇄 회로 기판에 적용됩니다. 이 버전은 2011년에 발행된 IEC PAS 61189-3-913의 첫 번째 버전을 취소 및 대체합니다. 이 버전은 기술 개정을 구성합니다. 이 버전은 고밝기 LED용 인쇄 회로 기판의 열전도성에 대한 시험 방법에만 초점을 맞춥니다.

The article discusses IEC 61189-3-913:2016, which outlines test methods for measuring the thermal conductivity of printed circuit boards designed for high-brightness LEDs. These test methods are applicable to printed circuit boards that contain surface mounted LEDs or LEDs embedded within electronic control devices. This edition of the standard is a technical revision, and it supersedes the first edition published in 2011. It focuses solely on the test methods for measuring the thermal conductivity of printed circuit boards for high-brightness LEDs.

記事のタイトル:IEC 61189-3-913:2016 - 電気材料、プリント基板、および他の接続構造および組立体のための試験方法 - 第3-913部:高輝度LED用電子回路基板の熱伝導率の試験方法 記事の内容:IEC 61189-3-913:2016は、高輝度LED用の印刷回路基板の熱伝導率に関する試験方法を規定しています。この試験は、表面実装LEDまたは電子制御装置(ECD)内に埋め込まれたLEDを含む高輝度LED用の印刷回路基板に適用されます。この第1版は、2011年に発行されたIEC PAS 61189-3-913の第1版を取り消し、置き換えるものです。この版では、高輝度LED用の印刷回路基板の熱伝導率の試験方法に焦点を当てています。

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...